The volatility of the ecommerce marketplace has been emphasized recently with unforeseen consequences for businesses slow to adapt. The pandemic has illustrated the importance of a flexible logistics operation while the continued reign of ecommerce over physical shop fronts necessitates investment into sophisticated packing solutions. Kite Packaging is market-leading with their range of automated machines and systems designed to enable rapid responsivity to changes in demand, scaling up or down packing processes accordingly. One of the greatest demands of online shopping is a fast delivery time, therefore, swift order fulfilment is crucial for repeat sales. Hence, the efficiency of automation is a strong rationale for investment, yet there is a wealth of further benefits granted by fronting the latest technological advancements.

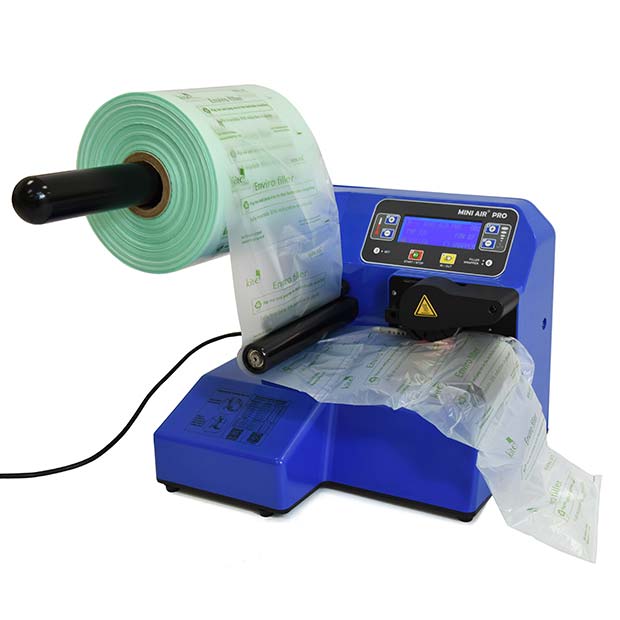

The Mini Air System supplied by Kite exemplifies this enhanced efficiency and flexibility. Capable of being loaded with eight different film types, including an 100% biodegradable starch-based film, the system automatically inflates air cushions. These machines can produce a customisable volume of air parcels dependent on current requirements with the Mini Air Pro being capable of inflating over 400 cushions per machine per day. These pads are excellent shock absorbers, resolutely shielding a range of products from damage by occupying the surrounding space and minimising movement. As such, the digitised machine allows a business to produce a considerably higher volume of in-the-box protection at a faster rate, ensuring quicker dispatch times and increased customer satisfaction.

The Mini Air System supplied by Kite exemplifies this enhanced efficiency and flexibility. Capable of being loaded with eight different film types, including an 100% biodegradable starch-based film, the system automatically inflates air cushions. These machines can produce a customisable volume of air parcels dependent on current requirements with the Mini Air Pro being capable of inflating over 400 cushions per machine per day. These pads are excellent shock absorbers, resolutely shielding a range of products from damage by occupying the surrounding space and minimising movement. As such, the digitised machine allows a business to produce a considerably higher volume of in-the-box protection at a faster rate, ensuring quicker dispatch times and increased customer satisfaction.

Kite’s most advanced carton sealing machines take this customisation a step further by automatically adjusting to the dimensions of the box being driven through the frame. As a result, an assortment of different sized cardboard boxes can be sent along the conveyer belt and sealed tightly with Kite’s industry standard machine tapes. Picking and packing operations are simplified and the degree of human intervention is reduced to allow for greater speed and productive use of time. In short, efficiency is massively increased to enable reliable order fulfilment to best exploit the soaring ecommerce market.

Programmable functions, like those available with the above products, enable quick reactions to maintain control over warehouse management, both avoiding overproduction or accelerating output depending on the circumstance. This reactivity is mirrored in the Paper Jet machine. This system runs at customisable speeds and sizes adjusted to suit the item being protected, awarding an advantage over operations relying primarily on manpower which cannot be scaled up or down with the same immediacy. The Paper Jet system dispenses 100% recycled paper and features an array of controls, including a ‘series mode’ permitting the user to program up to three different quantities of different measurements to rapidly pack certain products. Alongside responsivity, these functions free up a worker’s decision-making capacity for more complex procedures such as operating heavy machinery.

Automated elements can also regulate and strengthen your packaging process due to the increased physical capabilities of machinery as opposed to a solely human workforce. Kite’s pallet wrap machines can utilise greater power to stretch the film to its optimal elongation, helping each package to be uniform and economised as only the required amount of material is used. Companies can enjoy reduced wastage and improved sustainability through this automated process. The stretch wrap systems minimise the judgement calls and calculations needed from staff, consequently standardising packing processes throughout a warehouse which in turn makes it easier to adapt. This applies to all the automated systems: should a company underestimate the level of cushioning required to avoid damages, for example, the paper and air cushion dispensers can be reprogrammed in seconds as opposed to the training and reorganisation that would be needed to reform staff packing practices.

Many automatic machines also promote an improved health and safety of workers. The robotic pallet wrapping machine removes the need to transport pallets or load them onto a packing pad since the robot simply moves around the object wrapping as it goes. For operations packaging high volumes of orders, this level of technology is essential for maximising resources and ensuring effective wrapping every time, growing profits in the long-term. Kite’s compact gummed paper tape dispenser is a low-cost semi-automation option that similarly protects employees with its concealed blade that virtually eliminates the possibility of getting cut. This efficiency-boosting device smooths a medium-volume operation and is an economic alternative to a carton sealing machine.

Stocking over 2500 products on their ecommerce website and boasting seven Regional Distribution Centres capable of creating bespoke solutions, Kite Packaging provides automated machinery to grow almost any enterprising business. The ability to scale production almost instantaneously, best utilise human workers for more intricate tasks and of course, maximise efficiency identifies investment into automation as an integral tool for navigating unpredictable circumstances and solidifying a company’s position in the lucrative ecommerce market.

Comments are closed.