TracLogik working with several logistics businesses has developed a low-cost multi-technology solution to better track and manage reusable packaging and transport assets such as distribution cages, stillages, trolleys and pallets. The solution is designed to assist clients who are often faced with significant, regular expenditure to replace items lost during the course of business and dramatically reduce asset loss and improve operational efficiencies.

Operators within these sectors are of course acutely aware of the scale of the problem and the ongoing costs associated with the continued loss of these assets.

Operators within these sectors are of course acutely aware of the scale of the problem and the ongoing costs associated with the continued loss of these assets.

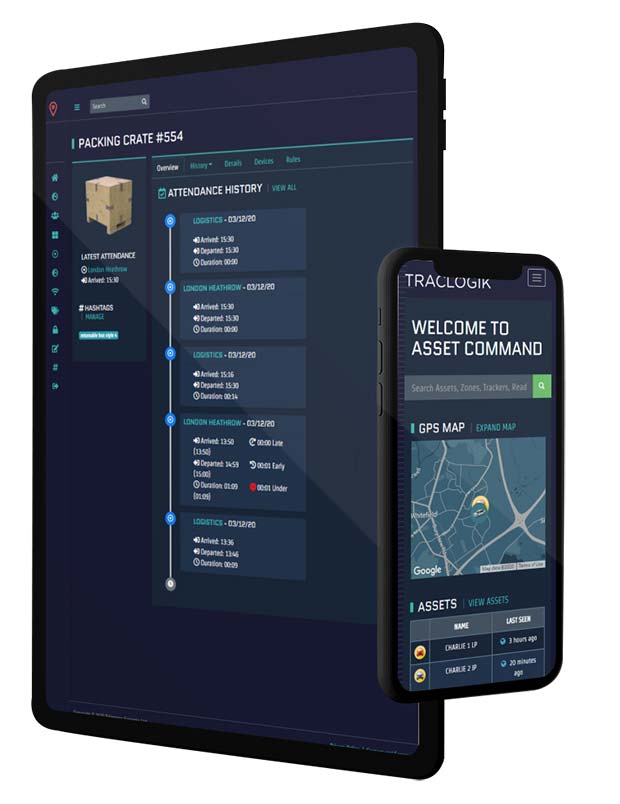

The TracLogik Solution combines GPS and Bluetooth Low Energy into a highly effective and versatile industrial packaging tracking solution to harness the strengths of both technologies.

By deploying our integrated GPS – Bluetooth receivers in vehicles, the system can provide a live position for assets tracked by Bluetooth, almost anywhere in the world. This gives full visibility of transport assets through the production facility, to the distribution centre, onto vehicles and at delivered locations.

The TracLogik System enables users to visualise the delivery of assets to partner facilities in real-time. If required, the system can be extended further quickly and cost effectively to provide coverage at the partner facility using Bluetooth with optional 3G/4G cellular communication should other connectivity for the devices be unavailable.

Businesses using pallets, cages, trolleys, stillages and other forms of returnable industrial packaging for customer deliveries or internal transport are often faced with significant, regular expenditure to replace items lost during the course of business.

In most cases these missing assets are rarely lost and often attributable to an absence of an effective asset management tracking system.

Working in partnership with several logistics businesses, TracLogik has developed a suite of flexible solutions that can be tailored to overcome these challenges.

The TracLogik solution effectively combines a broad spectrum of tracking technologies, including GPS, WiFi, BLE, RFID and low power wide area networks such as Sigfox and Lora.

The result is that the packaging asset tracking system, which was installed on the basis of a business case that predicted a payback period based around the reduction in the loss of assets is now also a go-to business tool for transport managers planning their next deliveries showing available capacity, throughput and being a source of asset-optimisation and rotation time reduction.

www.traclogik.co.uk/Resources/Tracking-Your-Returnable-Containers

Comments are closed.