Martin Styler, Sales Director at Ambassador Antalis looks at how the introduction of a stretch wrapping solution goes beyond just protecting your pallet to delivering some significant business benefits.

Most companies will already be aware of the importance of running an efficient warehousing and transportation operation, but all too often, the final stage of securing your palletised freight can be taken for granted. The cost of freight claims throughout the logistics, transport and shipping industry is huge, and yet, it’s an area of rich pickings for those who want to make cost savings. What’s more, by ensuring your goods arrive at their destination in perfect condition, it’s not just the goods that remain undamaged. You prevent damage to your company’s brand, its reputation and its relationship with its customer.

Whether handling high cost items, or relatively inexpensive ones, by the time they are all packaged together and palletised, the load takes on a significantly higher value. If this load was to become damaged or ‘shift’ in storage or transit, it could result in pallet rejection by the receiving warehouse as well as the delivery of unsaleable goods. The potential penalties of which can be extremely costly in terms of health and safety, as well as in time and money.

But, by taking the time to consider the best solution for your needs, and by investing in the right equipment to ensure a securely contained load, you will be securing a lot more than just your pallet!

Cost savings and increased safety can be achieved by the introduction of an automated or semi-automated stretch wrapping solution – one of the simplest, fastest and most cost effective ways of decreasing damage to palletised loads.

When loads become loose and fall apart, it requires costly manual labour to retrieve, re-stack and clear up any resulting damage. In addition, any movement in the palletised container during transit will result in costly rejection from the receiving customer – a situation that is becoming more prevalent with the increased introduction of automation in the warehouse.

When loads become loose and fall apart, it requires costly manual labour to retrieve, re-stack and clear up any resulting damage. In addition, any movement in the palletised container during transit will result in costly rejection from the receiving customer – a situation that is becoming more prevalent with the increased introduction of automation in the warehouse.

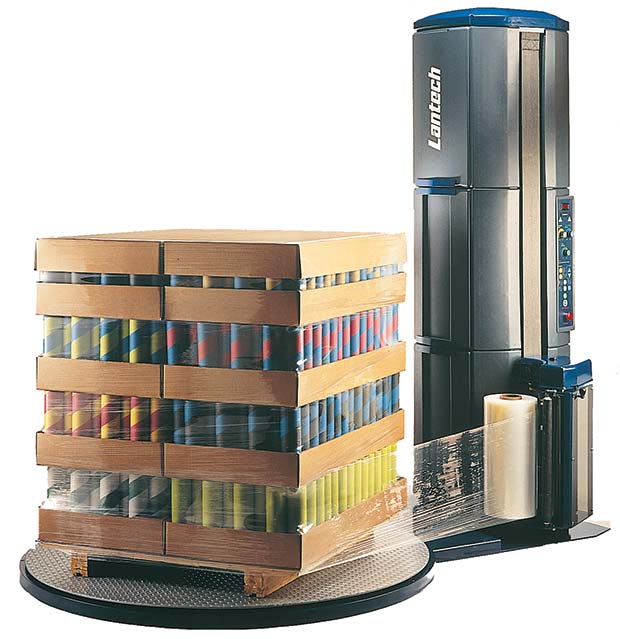

By using automatic and semi-automatic stretch wrapping systems, you can achieve a far superior load containment giving the pallet and the goods much greater stability, while actually reducing the cost of the film used. Quality wrapping machines such as our Lantech range of stretch wrappers have integrated powerful film delivery systems, which pre-stretches the film as it is applied to the pallet, increasing the yield of each roll of film by up to three times. As such, these wrapping solutions begin to have a significant impact on cost savings.

The introduction of an automated or semi-automated stretch wrapping system also reduces the level of labour intervention for each load, especially if you are manually wrapping 10 or more loads per day. This can enable you to reduce labour costs, deploy staff to other areas of your business, as well as reduce the risk of injury to staff having previously been responsible for manual wrapping.

While the introduction of stretch wrapping systems therefore deliver increased efficiencies and tangible cost benefits in terms of consumables, labour and damage compensation claims, they also help to secure the reputation of your business – something that is much harder to quantify, but equally, if not more important. So by securing your palletised load, you are also securing your reputation, your brand and the potential future of your business.

Tel: 0870 241 1466

Comments are closed.