Balancing the need to reduce environmental impact with business requirements can be a minefield. Fortunately, Antalis Packaging can offer a range of solutions.

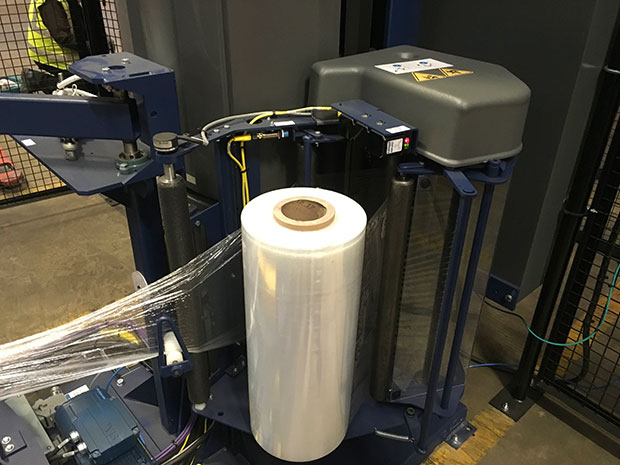

For most companies involved in the packing and distribution of goods, stretch film is one of the biggest areas of plastic usage. With environmental concerns an increasing focus and the new Plastic Packaging Tax now introduced, finding ways to reduce and manage the use of stretch film without negatively impacting business is a priority.

For most companies involved in the packing and distribution of goods, stretch film is one of the biggest areas of plastic usage. With environmental concerns an increasing focus and the new Plastic Packaging Tax now introduced, finding ways to reduce and manage the use of stretch film without negatively impacting business is a priority.

The Antalis Packaging team has been working hard to develop a raft of solutions that can help companies to achieve their business goals while keeping their environmental reputation intact.

Stretch Film Specialist at Antalis, Tom Reid, comments: “It starts with getting the right advice. What may work for one business may not be right for another. We’ve offered free audits across a range of packaging challenges for several years; the film assessments are in-depth, but quick, taking around 30 minutes. The process is invaluable for customers who are seeking to reduce their film consumption.”

Antalis Packaging’s free film assessment involves an exploration of a business’ existing film and machine usage before making recommendations that can, in some cases, bring about significant benefits.

Tom comments: “We have helped numerous companies make vast savings. One such example is a UK-based DIY company who took advantage of our assessment. By following our recommendations, they reduced their packaging waste by 75%, increased wrapping speed by 70%, and achieved a 60% reduction in overall costs. Similarly, we helped a manufacturer of pet supplies to reduce the cost of stretch film per pallet by 70%, increase wrapping speeds to 65 pallets per hour, and achieve a 70% reduction in packaging waste.”

Stretch film is frequently over-used, meaning that there are savings to be made for most companies. For those companies that may have already optimised their film usage, another way to reduce the impact of the Plastic Packaging Tax is by switching to a film containing a minimum of 30% recycled plastic, which, as with other plastic packaging products containing at least 30% recycled content, will be exempt from the tax. Tom continues: “We’ve been working with our suppliers to source and test new films. We currently have a number of options available in our Master’In range, covering both hand- and machine-stretch films, in a variety of thicknesses, dimensions, core types and colours.”

Tom advises that whatever route a customer chooses in terms of their stretch film use, it must be fully auditable, especially for those that are consuming more than 10 tonnes of plastic annually. Antalis Packaging can offer further support for customers by putting them in touch with third party companies who can help ensure compliance with the new tax.

Tom finishes: “It can appear to be a minefield, but with the right support and advice, there is a real opportunity here for packing and distribution companies to introduce some significant efficiencies to their business that can help them reduce their environmental impact and costs.”

For more information, please visit www.antalis.co.uk or contact Antalis on 0370 241 1466.

Comments are closed.