E-commerce has grown significantly and the average consumer is probably unaware of the mad scramble taking place behind the scenes at warehouses and distribution centers (DCs). But the rising demand in online sales isn’t the only challenge that warehouses are grappling with right now. Sustainability is a growing consumer concern too. A ‘Which?’ survey reports 48% of customers agree that “excessive packaging is one of the most annoying things about online shopping”.

Managing the labour crunch

Managing the labour crunch

Warehouses and DCs are also dealing with a labour shortage that was already in place pre-pandemic and became an even bigger problem for companies in 2021. “Companies are really fighting for affordable and available labour right now,” says Jo Bradley, Business Development Manager at Sparck Technologies (formerly known as Packaging by Quadient), whose 3D fully integrated automated packaging machines decrease the need for excess labour and can save companies the cost of up to 20 labourers per shift workers who can then be upskilled to more important activities.

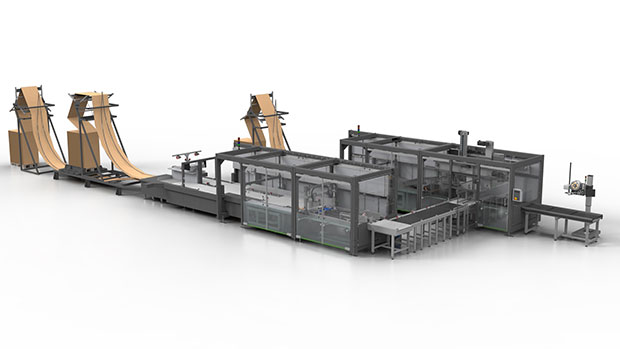

Using 3D scanning technology, Sparck Technologies’ automated packaging systems size, construct, weigh and label each individual order – regardless of whether it is made up of individual or multiple items in just a matter of seconds. The CVP Impack Automated Packaging Solution packs up to 500 orders per hour. With a cycle time as short as three seconds the CVP Everest can construct up to 1,100 fit-to-size boxes per hour.

Building the best box around its contents using automated packaging solutions takes the guesswork out of an otherwise costly link in the supply chain. They also reduce the amount of packaging material, time, and labour required to package orders in the fast-paced fulfilment environment. With many companies still using manual packaging processes, the warehouse that moves to an automated packaging solution saves significantly on labour. It can also save up to 50% on shipping volume (thanks to the optimal-sized boxes), and uses about 30% average less corrugated shipping material.

Automated packaging solutions like the CVP Impack and the CVP Everest also support scale—a major concern for companies operating in the expanding e-commerce sector. The company that typically packages 5,000 orders per day manually, for example, will have to find more employees, and additional equipment if it’s order volume suddenly jumps to 10,000 orders per day. The organization with an automated packaging solution in place can readily scale up to meet that additional throughput in a very safe, sustainable, and profitable manner.

Providing high levels of value

When e-commerce sales skyrocketed, the value proposition for automated packaging solutions shot up exponentially. Able to integrate directly with a company’s existing enterprise resource planning (ERP) or warehouse management system (WMS), the CVP Impack and the CVP Everest also provide valuable data that warehouse and supply chain managers can use to optimize their operations (e.g., what is the machine doing today? Are we on target with our throughput? What changes do we need to make?). “Our machines don’t just take an order, make a box, and get it ready to ship,” says Will Carder, Sales Engineer at Sparck Technologies. “They also give users the valuable data, metrics, and key performance indicators [KPIs] that they need to optimize their operations and plan for the future.” The automated packaging machines are also ergonomic and built to accommodate workers of all heights. “Our solutions are perfectly aligned with the workers who use them every day,” says Carder. The auto-boxers also take the pressure off employees that were previously tasked with boxing up to 35-45 parcels per hour. With today’s growing order volumes and fast delivery expectations, keeping up with these demands has become nearly impossible for manual-based packaging operations. “At some point, these companies will hit a peak period and find that they just don’t have the labour, physical space, or equipment to handle the volume anymore,” Carder says. When those existing processes break down, the end result is often an unhappy customer who doesn’t get his or her order on time, or that gets a tiny item packed in a gigantic box and filled with plastic air pillows or paper fill. With right-size packaging every parcel serves as a brand ambassador.

Down with plastic and bubble wrap

Most businesses stock a range of shipping box sizes. The idea is that the packer selects the smallest box for the contents, but that box may not always be the smallest that it can be. This creates a need for void fill material and airspace, essentially adding up to lost Pounds for the company. The latter is becoming increasingly important in a world where more consumers are focused on sustainability and on doing business with companies who care about the environment. “We help companies get rid of their plastic and bubble-wrap void fill materials,” says Bradley, “and because those companies also no longer ship ‘air,’ that translates into fewer trucks on the road.” With an automated packaging solution in place, companies can optimize all steps of package fulfilment by creating fit-to-size boxes for variable-dimension single- or multi-item orders. Using the CVP Impack and the CVP Everest, companies experience a quick return on investment, stay ahead of their competitors, and free up valuable labour to focus on more important activities other than packing boxes. More information on Sparck’s fit-to-size auto-boxing systems sparcktechnologies.com

Comments are closed.