Rocketing demand for online deliveries since the coronavirus outbreak has put even more pressure on retail distribution centres to pick, pack and deliver goods faster than ever.

For those companies operating high speed, high output automated warehouses, consideration should be given to the storage platform that you introduce to the system. When storing and retrieving bulky items in automated high-bay warehouses, we know our range of heavy duty, full perimeter plastic pallets on 5 runners are the preferred solution. But when smaller items in smaller quantities are required, there are other options such as Miniload systems that use specialist Miniload containers, which Goplasticpallets.com can now supply – and in huge quantities!

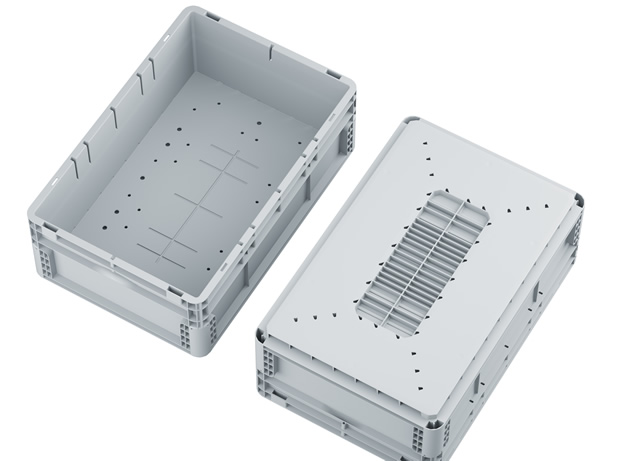

What is special about these Miniload containers

The Miniload container is a strong, durable picking crate available in various sizes to perfectly fit your automated storage system. Designed for repeated use, these customised containers come with various options which often relate to a specific provider’s automation. Special reinforced bases for extra strength (whether visible under the box or sandwiched between two base layers) solid or perforated sides, rigid or occasionally folding, special pick up locations and moulded-in bar codes – the options are almost endless.

Requirements for Miniload containers are normally vast, which reflects the density of these systems and the size of the companies operating them. Typical order volumes here are from 15,000 to 275,000 units, and even higher quantities as a system expands. Goplasticpallets.com and its European partners can deliver such volumes, to the required specification, with humour and efficiency.

How do Miniload containers accelerate order picking?

In a large automated warehouse with aisles upon aisles of racking, a stacker crane, conveyors and all controlled by a warehouse management system.

The stacker crane will locate the Miniload container with the desired goods, extract it from the racks and transfer it to the picking area, which will likely be located at the end or sides of the racks. At the picker area, the stacker crane deposits the Miniload container onto the conveyors and the appropriate item is picked from the container, before it is returned by the crane to the racks.

The Miniload containers, which are all of uniform size, shape and strength ensure that order picking takes place in one smooth, simple process, and at high speed!

What are the benefits of automated Miniload warehouses?

Aside from accelerating order picking, using Miniload containers in an automated warehouse offers considerable benefits:

- Optimal space usage – the high-density storage means that warehouse space is optimised with little or no wastage

- Multiply storage capacity – we have heard of retailers multiplying their storage capacity 10-fold by using an automated Miniload warehouse system

- Streamlined picking – as the containers are picked and delivered to the operator at exactly the same location, the operator can man his station, away from other operatives

- Rapid ROI – as the Miniload containers are designed for frequent, repeated use, the retailer will quickly see a return on their investment

- Safe environment – as the system is controlled by a warehouse management system with minimum human involvement, optimum safety is guaranteed.

If you manage or operate an automated warehouse, contact our team of experts today on +44 (0)1323 744057 or by emailing sales@goplasticpallets.com to find out how our Miniload containers can help you increase your output.

Comments are closed.