Not all businesses find fully automatic or semi-automatic machine wrappers an option. For some the outlay can be expensive, the application unsuitable for irregular load types and time is lost queuing up whilst others are using them. Sometimes going back to basics is called upon.

Traditional handheld films are a low cost solution to securing loads and can be purchased with extended cores for operator ease of application. These can be applied without a dispenser, however they come with their own user warning. Operators are often stooped over for long periods of time, causing back problems and user fatigue. The constant unravelling of the wrap can cause friction burns and because the tensioning of the wrap comes from the user, loads can sometimes be poorly secured and film inconsistently applied as a ‘that will do’ mindset sets in.

Traditional handheld films are a low cost solution to securing loads and can be purchased with extended cores for operator ease of application. These can be applied without a dispenser, however they come with their own user warning. Operators are often stooped over for long periods of time, causing back problems and user fatigue. The constant unravelling of the wrap can cause friction burns and because the tensioning of the wrap comes from the user, loads can sometimes be poorly secured and film inconsistently applied as a ‘that will do’ mindset sets in.

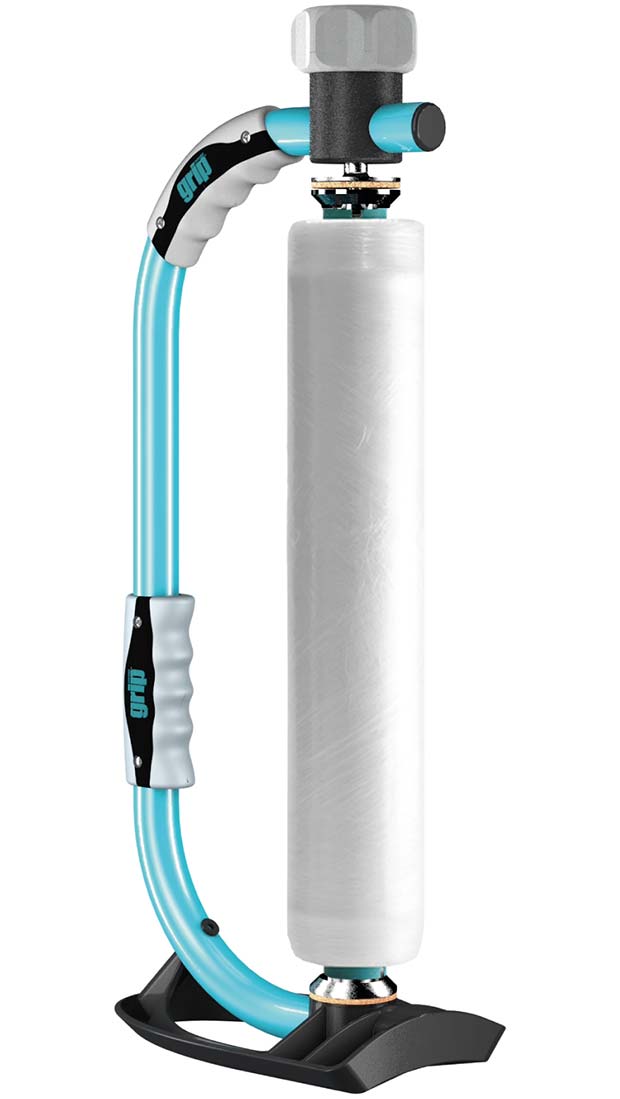

At allpack we have developed a revolutionary film dispenser that will place all regular hand film and dispensers firmly in the shade. The Grip™ Dispenser takes into consideration all aspects of operator safety and still delivers a professional wrapping system that is hard to beat. At only 800 grams, this lightweight ergonomic dispenser is perfect for one handed application and allows the securing of loads without grazed knuckles, friction burns to the hands or back pain. The unique twist and lock system creates speedy roll changeovers and allows the operator to set appropriate tension for the load. The hard wearing, tough skid plate permits the dispenser to be stood upright when placed down and acts as a buffer between operative and load. Plus, the Grip™ System delivers a professional uniform application of film to any load, even those with sharp, rough edges or irregular shapes.

We recommend using the Grip™ Dispenser with the incredibly powerful, self gripping film which contracts when applied. It has a secure non-slip core which is designed to work seamlessly with the dispenser with it’s self gripping formula adding to load stability. This unique film requires fewer wrap cycles per pallet, less roll changeovers, and it gives you 480m per roll. When compared to conventional films, Grip™ film will comfortably save you up to 40% in film usage, which is a massive reduction in plastic use and waste; a real environmental winner. Remember, with this film there’s no pulling, bending or endless cycles, which means your operatives won’t become so exhausted, making them more productive because of less downtime.

The Grip™ System, can do all of that, plus now you can accessorise your purchase with the Grip™ Hook. Made from reinforced glass, this hook really is built for everyday warehouse wear and tear. It can be mounted to racking and smooth surfaces and comes with a wall mounting kit that includes fixings, screwdriver, glue and glue pads; giving you no excuses to place it in the most convenient spot in your packing area. It really is inconceivable that a pallet wrapping system can offer all of this and be willing to give any business a free two week trial to road test it for themselves.

Those wishing to take up the trial will receive a Grip™ Dispenser and a case of eight rolls, so they can feel and see the benefits for themselves. If you’re not totally satisfied after the two weeks, collection will be arranged. If the Grip™ Pallet Wrapping System has simplified how you palletise, one of our representatives will make contact. Try it today and start feeling the benefits of the Grip™ Pallet Wrapping System, with a free two week trial. We’re quietly confident you won’t be disappointed.

Contact one of our representatives today: 01922 472 400.

Comments are closed.