The 1960 Mechanical Handling Show at Earls Court continued to produce examples of new ideas involving technological development and specialisation. Larger manufacturers tended to extend their ranges to meet ever-widening needs, whilst the small manufacturers concentrated on specific opportunities created through market experience and location.

The 1960 Mechanical Handling Show at Earls Court continued to produce examples of new ideas involving technological development and specialisation. Larger manufacturers tended to extend their ranges to meet ever-widening needs, whilst the small manufacturers concentrated on specific opportunities created through market experience and location.

Amongst the latter was Matling Ltd, who not only launched a new forklift truck but also a revolutionary control system for its speed and direction. Their new sit-on rider-operated machine called the ‘Lion’ had a one-ton lift to a height of 110 inches at 24-inch load centres. This four-wheeled battery powered truck was constructed without the normal control equipment associated with electric motors, but instead had a clutch fitted.

The system was designed by the company’s own engineers and in principle used a contactor for engaging the drive motor and a friction clutch to engage this with the transmission. The slip and resultant heat generated was dissipated through the clutch mechanism. With this new type of drive, the company claimed a smooth and more controlled handling of loads, especially in confined areas. These manoeuvres, up until this time, had relied on the rather jerky movements following a contactor flashing in and out under load, especially when the battery was well into a shift.

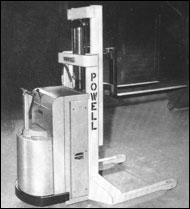

Another relatively small British manufacturer also took the opportunity of the show to add a new powered forklift truck to their range. Powell and Co of Burry Port, South Wales launched the ‘Vertostacker’ series VK/20 pedestrian controlled stacker as a specially designed truck to work in narrow confined areas. Lift capacity was 2,000 lb at 20 inch load centres to a height of 146 inches.

Other British manufacturers to launch new forklifts at this time were Montgomery Reid, B.E.V, Conveyancer and Coventry Climax. Shown for the first time at the exhibition was the latest forklift truck from Wingrove and Rogers, the B.E.V. model DH.33 with a lifting capacity of 30 cwt. This battery-powered model could be fitted with a choice of solid, cushion or pneumatic tyres, making the machine adaptable for most surface conditions.

Other British manufacturers to launch new forklifts at this time were Montgomery Reid, B.E.V, Conveyancer and Coventry Climax. Shown for the first time at the exhibition was the latest forklift truck from Wingrove and Rogers, the B.E.V. model DH.33 with a lifting capacity of 30 cwt. This battery-powered model could be fitted with a choice of solid, cushion or pneumatic tyres, making the machine adaptable for most surface conditions.

Montgomery Reid had a couple of new battery-operated machines on display. Both were rider operated and included a three wheeled forklift truck and a platform truck. This latter machine was made in two models; one of 10cwt and the other of 20cwt capacity. The forklift truck was called the ‘Ministack’ and had a lifting capacity of 1,680lb at 20 inch load centres to a height of 108 in.

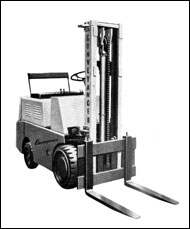

Conveyancer Fork Trucks Ltd displayed their new streamlined 4-24 series 3 forklift. It was capable of lifting 4,000lb at 24 in load centres up to a maximum of 14 ft and could be fitted with a choice of gas, petrol or diesel engine. These power units were offered from the Standard Motor Co series 23 C diesel or 87 mm petrol engines and connected to the transmission by a manual gearbox and dry clutch, giving two speeds in forward and reverse. The company claimed that the machine was designed for driver safety and comfort quoting the no-strain driving position, which was provided by the wide adjustable seat, ensuring that the operator had maximum visibility in all directions.

Another part of their display, but mounted outside the hall, was a ‘Shorland’ carrier handling a railway container. This followed an agreement made in 1959 between Conveyancer and Short Brothers and Harland Ltd that Conveyancer were to be the sole distributors at home and overseas of straddle carriers manufactured by Shorts in N. Ireland. The machines were originally known under the name of British Straddle Carriers but from this time carry the name of ‘Shorland.’

By James Brindley, Director, National Fork Truck Heritage Centre

To be continued…

Comments are closed.