Welcome to episode sixtyone in our exclusive series on the history of the fork lift truck, the machine which over the decades has revolutionised the face of materials handling around the world. We’ve now reached 1975, the year the Vietnam war ended, the Betamax video recorder was launched and Lancer Boss launched their largest ever fork lift truck, with a 130,000 lb lift capacity.

Welcome to episode sixtyone in our exclusive series on the history of the fork lift truck, the machine which over the decades has revolutionised the face of materials handling around the world. We’ve now reached 1975, the year the Vietnam war ended, the Betamax video recorder was launched and Lancer Boss launched their largest ever fork lift truck, with a 130,000 lb lift capacity.

Our writer is James Brindley, an acknowledged authority on fork lift trucks. James’s distinguished career has involved engineering and management roles with BT Rolatruc and serving as a Director of the FLTA, before he set up the National Fork Truck Heritage Centre in 2004 as Britain’s first such collection open to the public.

The Heritage Centre continues to need your support in 2011, and if you or your company would like to help in any way, you can contact James on the number below. Now sit back and enjoy the latest part of this fascinating series.

Episode 61: Vietnam war ends: first VCR on sale: Lancer truck breaks lift record

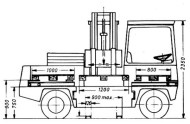

1975 started in a big way with the latest and largest offering from Lancer Boss. The K130/48 forklift with a lifting capacity of 130,000 lb was some 20 tons bigger than the Company’s previous giant, which was rated at 82,000 lb lift capacity. Four forward and reverse gears gave a maximum speed of 20 mph and the machine had the power and capability to cope with 1:4 gradients. Features included a braking system that braked the inner front wheel of a turn to assist the power steering on full locks and independent fork positioning, which was hydraulically controlled. An unusual feature was the counterweight, which was in two parts – a fixed main weight that was attached to the rear of the chassis and dynamic segments which were carried over the steering axle and designed to turn with it. This system was used to concentrate the mass and limit the total truck weight. The picture shows the K130’s physical size against a conventional 4,000 lb capacity forklift.

Although enjoying the success of their large truck launch, it would appear that they would now have to be watchful over their sideloader business. In stiff competition with the Lancer Boss sideloader trucks were the Italian companies of Battioni & Pagani, Fantuzzi and Benneli, who already had dealerships in Britain. Another company based in Italy, by the name of Baumann, had a new product and was now actively seeking such an opening in the market. Built in Italy and German-owned, their sideloader had a 3 in one function. By means of slide across platforms, on each side of the mast, the machine was able to pick up and transport three pallets at a time.

Early this year it was announced that a new company was to be formed to run a national pallet pool. A joint company of GKN Building Supplies & Services Ltd and the Australian Brambles Group, of which CHEP was a subsidiary, were to begin operations immediately. It was said that the pool would closely follow the mechanism that had been run and proved in Australia since 1957, when it was acquired by the Brambles Group. The history of CHEP began in 1945-46 after the war when the Australian Government took over from the United States Government a large quantity of mechanical handling machinery that was left behind by US Forces. This equipment was transferred to a rental pool run by the Government with the objective of stimulating industry to adopt better handling techniques. As a government department it was named the Commonwealth Handling Equipment Pool or CHEP. Part of the equipment that was rented was in the form of 46 in x 46 in pallets, which was considered by the Government to be of a domestically useful size. In 1957 the assets were sold to the Brambles Group, who adopted the inherited pallet size as a chance to offer the whole of Australian industry, and in particular grocery distribution, a standardised pallet size. The launch of the pallet pool in Britain was adapted to suit our grocery distribution organisations, including the size of pallet. The pallet size chosen was the UK’s most popular of 1000mm x 1200mm, and was of the perimeter boarded type. This latter choice however was not popular with many, which included owners of automated warehouses and users of stacker trucks. One acronym that was not altered however was CHEP, by which it is still known today, even though its Commonwealth connotations are gone.

Early this year it was announced that a new company was to be formed to run a national pallet pool. A joint company of GKN Building Supplies & Services Ltd and the Australian Brambles Group, of which CHEP was a subsidiary, were to begin operations immediately. It was said that the pool would closely follow the mechanism that had been run and proved in Australia since 1957, when it was acquired by the Brambles Group. The history of CHEP began in 1945-46 after the war when the Australian Government took over from the United States Government a large quantity of mechanical handling machinery that was left behind by US Forces. This equipment was transferred to a rental pool run by the Government with the objective of stimulating industry to adopt better handling techniques. As a government department it was named the Commonwealth Handling Equipment Pool or CHEP. Part of the equipment that was rented was in the form of 46 in x 46 in pallets, which was considered by the Government to be of a domestically useful size. In 1957 the assets were sold to the Brambles Group, who adopted the inherited pallet size as a chance to offer the whole of Australian industry, and in particular grocery distribution, a standardised pallet size. The launch of the pallet pool in Britain was adapted to suit our grocery distribution organisations, including the size of pallet. The pallet size chosen was the UK’s most popular of 1000mm x 1200mm, and was of the perimeter boarded type. This latter choice however was not popular with many, which included owners of automated warehouses and users of stacker trucks. One acronym that was not altered however was CHEP, by which it is still known today, even though its Commonwealth connotations are gone.

By James Brindley, Director, National Fork Truck Heritage Centre.

To be continued…

2 Comments

We are a group of volunteers and opening a new scheme in our community.

Your web site offered us with valuable info to work on.

You’ve done an impressive job and our entire community will be thankful to you.

Nice post. I was checking continuously this blog and I’m impressed! Extremely useful info specifically the last part 🙂 I care for such information a lot. I was seeking this particular information for a very long time. Thank you and good luck.