The Autotote is the next development in intralogistic containers. It is perfectly designed to offer smooth silent running, with its double skin strengthen base and cantilever edges.

The innovation of the Autotote’s double skin concaved base is designed to run smoothly and quietly along automation systems, while maintaining a high level of durability and ultimate strength. The diagonal ribbing strengthens the base to the highest standard and the 100% closed underside protects the conveyor system, helping to save cost on belt maintenance, while improving grip and speed.

The innovation of the Autotote’s double skin concaved base is designed to run smoothly and quietly along automation systems, while maintaining a high level of durability and ultimate strength. The diagonal ribbing strengthens the base to the highest standard and the 100% closed underside protects the conveyor system, helping to save cost on belt maintenance, while improving grip and speed.

The base consists of a cantilever edge that reduces noise on rollers and a chamfered side edge that provides a smoother transition between linking conveyors or during a directional change. The Autotote also has several strengthened interaction points to optimise movement within an automated shuttle system.

The base consists of a cantilever edge that reduces noise on rollers and a chamfered side edge that provides a smoother transition between linking conveyors or during a directional change. The Autotote also has several strengthened interaction points to optimise movement within an automated shuttle system.

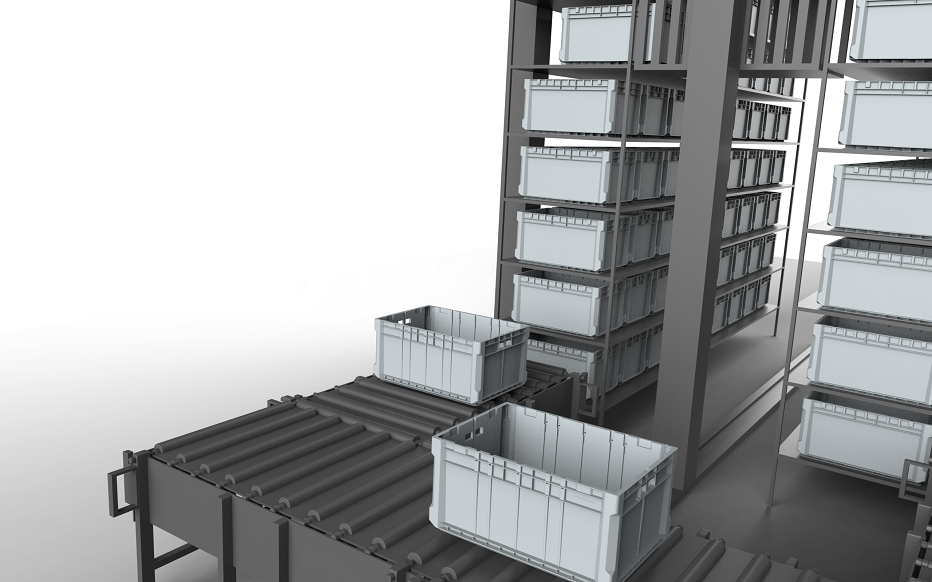

Intralogistics and automation warehousing is becoming increasingly popular throughout the globe and is pushing businesses towards future proofing their supply chains. The Autotote advances all aspects of the supply chain from improving accuracy and speed, to reducing waste, and is suitable for all conveyors and transfer units, with an optimised base design that reduces deflection and noise.

Intralogistics and automation warehousing is becoming increasingly popular throughout the globe and is pushing businesses towards future proofing their supply chains. The Autotote advances all aspects of the supply chain from improving accuracy and speed, to reducing waste, and is suitable for all conveyors and transfer units, with an optimised base design that reduces deflection and noise.

Dividers can be added to the Autotote for versatile subdivisions, allowing up to 1/8 segregation for increased fill and SKUs available per system. Other various optional extras are available and can help modify the Autotote dependant on the specific needs of the company, including; easy recycle lift lid, automated barcode and label application, and both open or closed handle options.

Loadhog can manufacture the container with a blend of recycled and virgin material, helping you to protect your supply chain’s carbon rating. A circular economy is now globally recognise and promotion of this within your supply chain will not only future proof your business but ensure a long life investment.

As the importance of automation continues to grow, Loadhog’s new innovation is set to improve and modernise operations processes across a range of sectors. The global intralogistics market is expected to grow at an annual rate of 15.5% from 2020 to 2030, encouraging businesses to migrate from manual to automated warehousing and invest in the most reliable and efficient totes for a smooth process.

The first Autotote to be produced will be 650mm x 450mm footprint, 320mm height – Loadhog will also be offering heights of 220mm, and 400mm.

Product Specifications

- 600mm x 400mm: 220mm, 270mm, 320mm, 420mm

- 650mm x 450mm: 220mm, 320mm, 400mm

- Unit payload (for any material): 50kg

- Temperature range: -20 +40

- Versatile dividers: allows up to 1/8 container segregation.

Comments are closed.