From 0 to 100 instantaneously

As a systems provider, ABM Greiffenberger develops and manufactures drive systems for stationary and mobile intralogistics applications. Upon request, customers can be supplied with individual solutions allowing them to reduce their costs. This is made possible by the ABM’s close cooperation and partnership with customers.

As a systems provider, ABM Greiffenberger develops and manufactures drive systems for stationary and mobile intralogistics applications. Upon request, customers can be supplied with individual solutions allowing them to reduce their costs. This is made possible by the ABM’s close cooperation and partnership with customers.

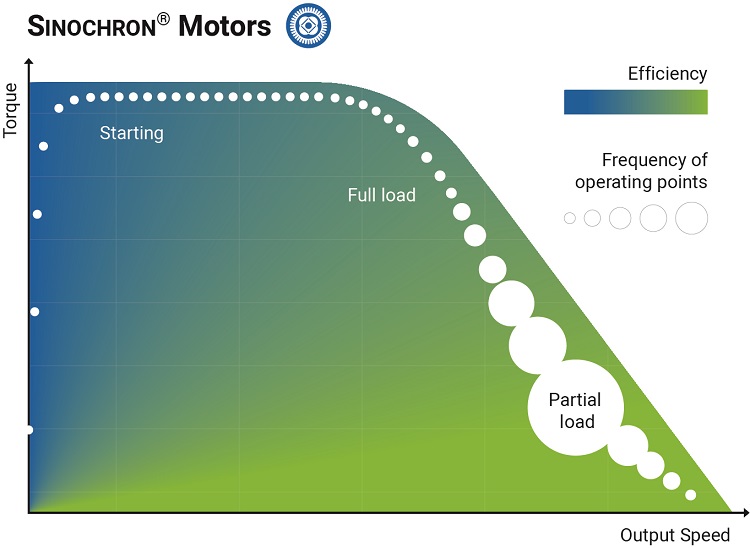

Manufacturers of intralogistics solutions want highly efficient drives that are always available and run without any problems. ABM helps customers slash costs and thus profit from a fast ROI. The motors are extremely efficient, especially in the partial-load operational range the systems primarily operate in. The Sinochron motor operates without sensors and has a high starting torque. This is particularly important in intralogistics applications because conveyor systems often have to move heavy loads from a standstill: with a speed control range of 1:200, the Sinochron series can immediately apply the full starting torque to move stationary loads– virtually from 0 to 100.

Manufacturers of intralogistics solutions want highly efficient drives that are always available and run without any problems. ABM helps customers slash costs and thus profit from a fast ROI. The motors are extremely efficient, especially in the partial-load operational range the systems primarily operate in. The Sinochron motor operates without sensors and has a high starting torque. This is particularly important in intralogistics applications because conveyor systems often have to move heavy loads from a standstill: with a speed control range of 1:200, the Sinochron series can immediately apply the full starting torque to move stationary loads– virtually from 0 to 100.

The Sinochron series are permanently excited synchronous motors, which, thanks to their special compact design, are perfect for sensorless operation. Without the encoder, users benefit from significantly reduced system costs and high system availability – both points are important advantages for the total cost of ownership. The smallest IEC frame size of 63 can already reach nominal torques of 4.5 Nm.

The motor is supplied with 400 V. This makes project planning much easier because multiple drives are operated from one power supply and connected in daisy chain.

With an intelligent modular design, ABM can find the right solution for every application. Various gearbox designs are also available and tuned to the performance values of the respective motors. Thanks to its modularity, the drives can also meet special requirements of the system manufacturer with standard components. With this, the systems provider also reduces the number of possible variants. If higher torques are required, the motor can be combined with a gearbox. Various mechanical and electrical plug-and-play interfaces simplify the installation.

Wearless direct drive, gearless, without brakes, energy-efficient and with high availability: all this is what makes the ABM solutions suitable for roller conveyors. If a gearbox is attached to the motor the user can handle higher loads and still profits from the advantages of the Sinochron motors.

Thanks to the modified modular solutions, the customer profits from fast availability. ABM supports manufacturers with efficient drive solutions – in AGVs, conveyors, lifting gear and forklift trucks or in cold storage facilities.

Comments are closed.