Established in 1999, inotec UK has become a worldwide leader in developing, manufacturing and installing durable labels, floortags and line marking solutions. With customers in a variety of industries including warehousing and logistics, healthcare and automotive, inotec has developed a range of products to meet customers’ specific requirements.

Based in Germany, inotec GmbH’s headquarters is home to its head office as well as its product development, testing and manufacturing facility. Over 20 years ago, inotec built its own laboratory to ensure its innovative products meet and maintain the high standards required by customers. Today, the company produces around 300 million labels a year for customers across Europe and many other countries around the world.

Product testing – Creating specification data

One of the most fundamental aspects of developing labelling solutions is the product testing. Product testing enables inotec to guarantee how long labels will last in a particular environment. This allows it to predict a lifespan for each label type.

On occasion, inotec is asked to produce bespoke labelling solutions, having its own in-house laboratory and testing facility is essential to do this successfully.

There is a standard specification sheet produced by inotec to advise customers of product durability and life span. This spec sheet is derived from data collected during its core testing procedures including weather resistance, erosion resistance, adhesive durability and label readability. The thorough testing allows inotec to provide customers with a report which details exactly how long it guarantees its labels will resist such conditions.

Weather testing – UV light and water resistance

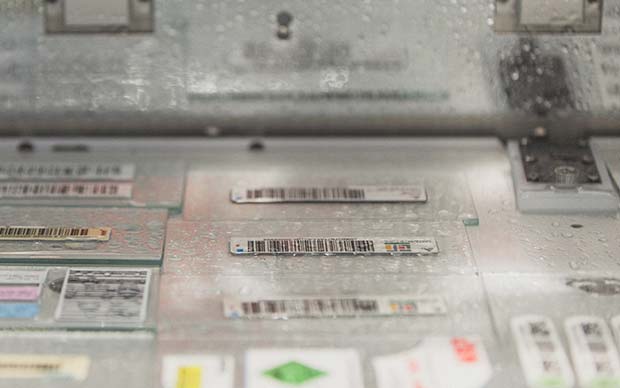

To test a label’s durability against weathering, both UV light and water, inotec uses high specification Q-SUN machinery at the German testing facility. These machines are used by professional laboratories worldwide for the weather testing of materials and coatings. The Q-SUN testing chambers allow inotec’s technicians to continuously run alternating UV light and water cycles to replicate realistic weather patterns. This allows inotec to examine how the labels will last when used outside.

In-mould label testing for plastic crates

The range of in-mould labels produced by inotec has been specifically designed for use within environments that require a high level of hygiene. The in-mould labels are placed inside the mould before the injection of the molten plastic. This allows the label to become a permanent fixture on the surface whilst the crates are produced.

The advantage being that in-mould labels have no adhesive edge so no bacteria or water can sit underneath the label. This is essential not only to maintain hygiene levels but also to ensure that the in-mould labels can endure intensive wash processes for a long lifespan – sometimes up to 10-15 years.

The inotec Label Competence Centre

Within the laboratory, there is a dedicated Label Competence Centre that continuously tests the quality of products to ensure they consistently meet inotec’s specification standards. The specification sheet confirms all labels go through the same testing for water resistance, wash resistance, UV light and temperature resistance and scratch resistance.

Labels are tested to check factors including the quality of the label itself, the adhesive, the reading quality of the barcode, the sharpness of lines and the contrast between black and white. All materials and products are not only tested to the required specification, but also to the point of failure so the limits within various environments can be defined.

As well as testing inotec’s products, the Competence Centre also tests materials from suppliers to ensure that inotec’s products uphold the expected high standards.

Meeting inotec’s specification standards

Test processes for the specification sheet include chemical and acid substance testing. The lab can submerge labels into a range of chemicals for various amounts of time to ensure they are resistant to damage. In addition to UV light resistance, inotec also test labels for heat resistance.

For even the standard specification of testing, inotec’s labels must be resistant to +90 degrees Celsius and -32 degrees Celsius for 24 hours. On request, the lab can test label heat resistance up to 1,200 degrees Celsius.

In order to check scratch resistance, inotec tests labels with a Taber test. The Taber test machine adds weight to a pen which pushes down onto labels to see how the surface withstands scratching.

Medical and pharmaceutical label testing

For environments that require labels to be rotated, such as medical test tubes, inotec tests the adhesive strength of the labels using centrifuge machines.

inotec’s Competence Centre also tests for extremely low temperatures, ranging from minus 18 down to minus 85 degrees Celsius. This is vital for checking labels and adhesives can withstand being frozen, stored and thawed without compromising their performance.

Label adhesion strength testing

To examine label adhesives and the strength of the glue, inotec has devised an adhesion test using clamps. A piece of the adhesive is attached to a test plate and then lifted to see how many newtons’ per 20 millimetres squared it takes to pull the adhesive away from the plate.

RFID labels – Testing scanning competencies

The performance of RFID inlays is also verified at inotec’s Competence Centre. The technicians can test the maximum reading distances to ensure they meet customers’ required needs. The RFID inlays get tested through various standards, such as chemical assessments, and then have reading distance capabilities tested.

Quality Testing Department

In addition to producing and testing labels, the inotec head office also houses a focused Quality Testing Department. Here, technicians check every single label of every order before they are despatched to the customer. When checking the quality, labels are examined for the print quality, correctness of barcodes and material quality. For RFID chip labels, quality testing includes checking for both readability and if the chip content is correct.

The importance of an invested supplier

Having such an extensive product development and testing processes is something that inotec prides itself on. The data reports produced in the Label Competence Centre and laboratory ensure inotec’s specification sheet is consistently accurate. The company can guarantee every batch of materials and every label produced always meet the required standard of quality with no discrepancies between products.

If you would like to speak to inotec UK to discuss your labelling needs and find a reliable solution, please call 01482 654466 or email info@inotec.co.uk to arrange a consultation.

Comments are closed.