![]() Welcome to episode fiftysix in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world. In this episode we’re up to 1970, the year the Beatles broke up.

Welcome to episode fiftysix in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world. In this episode we’re up to 1970, the year the Beatles broke up.

Our writer is James Brindley, an acknowledged authority on fork lift trucks. James’s distinguished career has involved engineering and management roles with BT Rolatruc and serving as a Director of the Fork Lift Truck Association, before he set up the National Fork Truck Heritage Centre in 2004 as Britain’s first such collection open to the public.

The Heritage Centre continues to need your support in 2011, and if you or your company would like to help in any way, you can contact James on the number below. Now sit back and enjoy the latest part of this fascinating series.

Episode 56: 1970 – Beatles break up, Lansing Bagnall launch used truck business

Despite the trend away from battery powered forklifts in favour of I/C engine forklifts that was reported by manufacturers at the beginning of 1969, the total population of battery powered equipment including industrial trucks was very much on the increase. This was the conclusion of the Electric Vehicle Association (EVA), in January 1970.

The EVA report stated that in industry the total number of electric trucks at this time was 75,000 of which 70% of this figure was for forklifts and equipment used in materials handling. One company taking full advantage of this industry need was Conveyancer. who made an addition to its “Starline” range with its new E8 model forklift with an 8,000 lb lifting capacity at 24 inch load centres. Power was supplied by a 72 volt battery through an S.C.R Controller.

Another company leading the way was Lansing Bagnall, who launched two new reach trucks and an electronic controlled upgrade to the P.O.E.P 5, an already proven powered pallet truck. The reach trucks included the FRER 6 for the lighter end of the market and the model FRER 8 for use in hazardous flammable areas. This manufacturer also established a new company this year to accommodate the many small businesses which could not afford a new truck or could not show a sufficient return on a new truck investment. The company’s name was “Regentruck” and supplied overhauled Lansing machines. This equipment was bought up as part exchange in a new deal and rebuilt to the original specification so that a warranty could be given. The purchaser of this equipment was then able to take full advantage of the company’s after sales service normally supplied to new truck sales.

Most of the new equipment for this year was exhibited at the Mechanical Handling Exhibition in May, and included a 4 way stacker. This four directional stacker was made by Sidetracker Engineering Ltd. and was the brainchild of Peter Dobson, who was formerly employed by PERA as a consultant. One of the features of the truck was that separate load wheels were used for forwards and sideways travel. The latter wheels were jacked down at the push of a lever and elevated the truck and its forward/reverse load wheels clear of the ground. Traction was maintained through all four directions by a spring loaded steering/drive unit. The lift jacks, fork carriage and directional drive were operated by an electric motor driving a constant displacement pump. As this machine was not fitted with a reach facility any pallets at ground level needed to be elevated above six inches for clearance of the outrigger legs. One extremely useful feature of this truck design was that both sets of load wheels could be brought into contact with the ground at the same time. This action locked the trucks movement in any direction and made it easy for applications that required spot loading such as locating press dies.

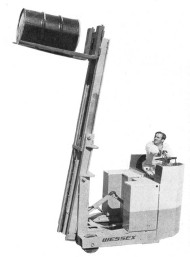

Another machine recently released was a reach truck by the Wessex Company of Poole. This forklift truck is of the tilting mast type with a lifting capacity of 4,500 lbs at 24 inch load centres to a height of 118 inches. At the centre of the trucks design is a double acting hydraulic cylinder which was designed and manufactured by the Company in its own workshops. The cylinder extended 32 inches from a closed length of 27 inches. In common with all of its other battery powered vehicles the reach truck was fitted with the special plug-in module control system ,which was developed in conjunction with Sevcon Engineering. In the words of the management this device permits programming of the machine for specific duties without the need to reconfigure the logic box. At this time the Wessex Company also announced the launch of a pantagraph version of its reach truck. This was an interesting development as to date there was only one other fork truck manufacturer that was offering the two concepts – the company of Conveyancer Fork Trucks Ltd.

Another machine recently released was a reach truck by the Wessex Company of Poole. This forklift truck is of the tilting mast type with a lifting capacity of 4,500 lbs at 24 inch load centres to a height of 118 inches. At the centre of the trucks design is a double acting hydraulic cylinder which was designed and manufactured by the Company in its own workshops. The cylinder extended 32 inches from a closed length of 27 inches. In common with all of its other battery powered vehicles the reach truck was fitted with the special plug-in module control system ,which was developed in conjunction with Sevcon Engineering. In the words of the management this device permits programming of the machine for specific duties without the need to reconfigure the logic box. At this time the Wessex Company also announced the launch of a pantagraph version of its reach truck. This was an interesting development as to date there was only one other fork truck manufacturer that was offering the two concepts – the company of Conveyancer Fork Trucks Ltd.

By James Brindley, Director, National Fork Truck Heritage Centre.

To be continued…

If you would like to support the National Fork Truck Heritage Centre, please call James Brindley on 0780 195 4167

2 Comments

I have a Stacker and suddenly one of the wheels has Jammed .

as if some gear or ?? inside the steerable wheel has come loose.

Can ony one sdvise me where to stsrt

It is a very old unit and in wonderful condition except for this little problem that occured after left standing for 3 months in the cold Canadian winter.I live in Ottawa

At first I thought it was the Hand brake but after jacking up I found the the wheel moves a few degrees before it jams.