Hyundai Heavy Industries Europe (HHIE) will present an extensive display of its latest, updated range of industrial trucks at the IMHX materials handling exhibition at the NEC, Birmingham in November. The Hyundai display will include eight models from 1.4 to 16 tonnes lift capacity, including electric, LPG and diesel-powered lifttrucks, stackers, pallet and reach trucks, and it will be the first European showing of the all-new 5t capacity model 50L-7A – the first of a new -7A Series of LPG lift trucks.

Hyundai Heavy Industries Europe (HHIE) will present an extensive display of its latest, updated range of industrial trucks at the IMHX materials handling exhibition at the NEC, Birmingham in November. The Hyundai display will include eight models from 1.4 to 16 tonnes lift capacity, including electric, LPG and diesel-powered lifttrucks, stackers, pallet and reach trucks, and it will be the first European showing of the all-new 5t capacity model 50L-7A – the first of a new -7A Series of LPG lift trucks.

At its modern and recently expanded research and development centre in Ulsan, South Korea, Hyundai has been concentrating on consolidating its industrial equipment range to provide a broad spectrum of choice in all industrial materials handling sectors, meeting the latest environmental requirements and maintaining Hyundai’s legendary reputation for performance and reliability.

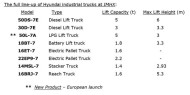

The full range of Hyundai industrial trucks now provides some 75 models altogether, from 1.4 to 18t capacity, with many variants including diesel, battery-powered and LGP-powered lift-trucks, electric reach and stacker trucks, pallet trucks and a handy compact platform/tow-truck.

These machines are complemented by a wide range of specialist handling equipment and attachments, and all provide a high level of driver comfort and efficient performance for modern factory and warehouse operations.

New -7A Series

The latest model to be introduced, and being shown for the first time at IMHX, is the new top of the LPG range model, the 5t-capacity 50L-7A. This is the first of a new series of -7A LPG models which will include 3, 4 and 4.5t models as well as the 5t machine being shown. Full details of the rest of the range will be available shortly.

Amongst the main features of the new -7A range are : newly configured engines to conform with Tier 4 emissions standards, and a big change in the drive-line, with a new front axle arrangement. In the new system, the transmission has now been mounted independently of the front axle, with an intermediate drive-shaft. This effectively eliminates any drive-line vibrations for smoother operation and operator comfort. There is also a new, independent, more easily accessible handbrake.

A new innovation is the introduction of OPSS (Operator Presence Sensing System), which detects when the operator is not properly seated and neutralises all hydraulic and drive functions.

A new innovation is the introduction of OPSS (Operator Presence Sensing System), which detects when the operator is not properly seated and neutralises all hydraulic and drive functions.

Other models in the -7A Series will be introduced progressively in the coming months.

Commenting on these new developments and Hyundai’s broader outlook, Marketing Manager Michel de Weert said, ‘‘We are looking ahead very positively. Hyundai has invested millions in new research and production facilities in Ulsan to ensure continuity of our product development and treble production capacity in the new, even more efficient main manufacturing plant.

‘‘The objective is to grow our global market share in all sectors of construction/mining and industrial equipment by providing end-users the best available choice, and building on our reputation for product reliability and value-for-money.’’

Hyundai

Comments are closed.