Dürkopp Fördertechnik, a market leader in the manufacture and installation of systems which handle the flow of both flat and hanging goods, has completed a new system for the Netrada Group – a leading German e-commerce service provider.

Dürkopp Fördertechnik, a market leader in the manufacture and installation of systems which handle the flow of both flat and hanging goods, has completed a new system for the Netrada Group – a leading German e-commerce service provider.

Netrada, which is based in Hanover-Garbsen, is a subsidiary of logistics company D+S Europe, one of the leading e-commerce firms in the fashion industry. Employing more than 1700 people, it has become a specialist in on-line selling. However, the group’s sphere of activity goes beyond just the management of online shops and now includes storage, order-picking, packaging and dispatch – right the way through to managing returns and refunds. This integrated approach allows the e-commerce specialist to offer its clients a comprehensive service. Every year the company delivers several million packages for other companies, mainly in the textiles and clothing sector.

“A particular feature of Netrada is our optimised returns management. Goods returned by customers go straight back into the range available for sale”, says Thiess Johannssen, a spokesperson for the company.

Dürkopp’s split tray sorting system helps ensure Netrada’s handling process for returns is as effective as possible.

Annette Sommer, Dürkopp Fördertechnik’s General Manager in the UK, said: “Customers do not always keep everything they order. With clothes in particular, the same items are often ordered in different sizes so that the customer can try them on in the comfort of their own home and select the right style and size.

“However, this can obviously lead to a significant flow of return goods so it is naturally important to be able to manage the returns process efficiently and quickly. I am delighted that Netrada, which focuses on the wholesale outsourcing of online shops specialising in the fashion industry, uses our new split tray sorter to enable them to meet their targets.

“However, this can obviously lead to a significant flow of return goods so it is naturally important to be able to manage the returns process efficiently and quickly. I am delighted that Netrada, which focuses on the wholesale outsourcing of online shops specialising in the fashion industry, uses our new split tray sorter to enable them to meet their targets.

“In the online shopping sector, efficiency and speed are of paramount importance, particularly when it comes to returns management. Our sorter can be used to process several thousand items per hour, quickly separating returns and reintegrating them into the warehouse.”

The Dürkopp equipment is capable of sorting items into either containers or boxes so they are ready for dispatch – or, in Netrada’s case, ready to be returned to the warehouse.

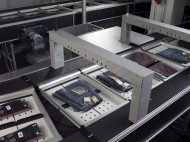

The goods to be sorted are placed by hand into the sorter tray at one of six loading points – the split tray system itself is in a space-saving, elongated horseshoe shape measuring around 29m x 15m. The sorting trays are 60cm x 45cm, consisting of two half trays set next to each other, which automatically open upon reaching the desired point, placing the item directly into the container below.

In order that the system can recognise very small bar codes of up to 8mm x 33mm – even through a layer of plastic wrap – extensive tests were carried out to find the best read system. This proved to be a combination of a CCD (Charge-Coupled Device) sensor camera and a laser scanner which were duly installed.

Once the item of clothing has been scanned, the warehousing management system indicates the appropriate delivery station. A light beam at every delivery point recognises full containers and a light signal then tells the operator to change over. Containers of sorted goods are made available in a selected area of the warehouse and an operator then returns them to their storage place in the order-picking section.

At each of the feeder points, the conveyor belt drops to a height of 80 cm, so that the employee can load the goods from a standing position. The sorter, however, is raised above the level of the points, so as to be able to reach the containers below.

At each of the feeder points, the conveyor belt drops to a height of 80 cm, so that the employee can load the goods from a standing position. The sorter, however, is raised above the level of the points, so as to be able to reach the containers below.

If extra capacity is required, the split tray system is very easy to enlarge due to its modular design, and Netrada’s system has room for an extra 30 delivery units. These are very simple to retrofit during operations, without any need for the conveyor belt to be extended.

Dürkopp Fördertechnik’s customers are located across the U.K. and mainland Europe and include blue chip names such as Next, Marks & Spencer, John Lewis, Asda, C&A, Inditex/Zara and H&M.

Dürkopp Fördertechnik Tel: 01455 299892 Email: annette.sommer@duerkopp.com www.duerkopp.co.uk

Comments are closed.