In today’s dynamic business environment, industries ranging from pharmaceuticals to dairy are embracing Automated Storage and Retrieval Systems (ASRS) to elevate their logistics supply chains. ASRS systems promise heightened picking accuracy, accelerated operations, and optimised warehouse space utilisation, enabling seamless warehouse management with minimal labour input.

The effectiveness of an ASRS hinges on the precision of its components. Factors that hinder, damage, or introduce confusion to the machinery translate into both time and financial losses. Traditional wooden pallets, with their tendency for splintering, loose nails, and moisture absorption, alongside plastic pallets susceptible to Plastic Creep and Deformation over time, pose challenges. Additionally, both wood and plastic pallets fall short in fire safety risk assessments.

The effectiveness of an ASRS hinges on the precision of its components. Factors that hinder, damage, or introduce confusion to the machinery translate into both time and financial losses. Traditional wooden pallets, with their tendency for splintering, loose nails, and moisture absorption, alongside plastic pallets susceptible to Plastic Creep and Deformation over time, pose challenges. Additionally, both wood and plastic pallets fall short in fire safety risk assessments.

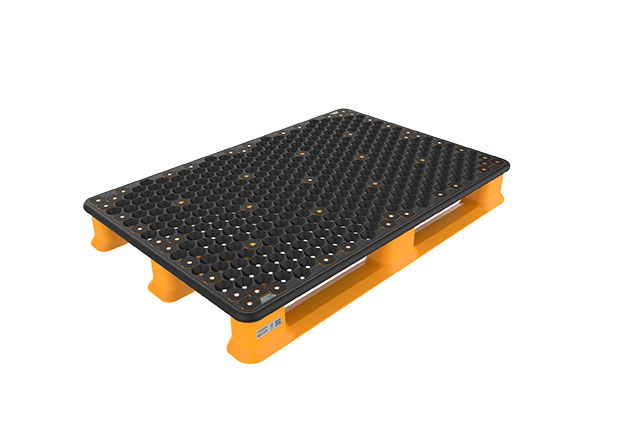

For a precision-demanding mechanical system, an equally precise pallet is imperative. Enter the Ecolite ER64.2 hybrid pallet, distinguished by its uniform dimensions, stable weight, and robust construction, making it the ultimate choice for ASRS applications. Choosing Ecolite’s hybrid platform mitigates disruptions, ensuring a smooth flow in the supply chain and enhancing overall throughput.

Highlighted features of Ecolite pallets seamlessly integrated with ASRS include:

Construction: Top deck produced from 2 thin steel panels, double pressed and laser welded. Skids/runners produced from HDPE with imbedded fixings and anti-slip features.

High Strength to Weight Ratio: Weighing a mere 20kg and supporting a safe rackable load of 1800kg (ISO 8611), the Ecolite ER64.2 hybrid pallet has the market leading strength-to-weight ratio.

Highly Rigid: The Ecolite ER64.2 hybrid pallet, thanks to its highly rigid steel panel top deck, exhibits less than half the deflection at full load compared to equivalently rated plastic pallets. Unlike plastic pallets prone to permanent deflection over time, the Ecolite ER64.2 immediately returns to its original position after deloading.

Reduced Downtime: The pallet’s robust construction resists damage, minimising malfunctions, and reducing downtime. A laser welded steel edge bumper reinforces the pallet and protects the load from side impacts. Reduced Foreign Object Damage: The steel and plastic construction cannot splinter or produce debris, preventing Foreign Object Damage (FOD) in machinery.

Modular Design: In case of wear or accidental damage, the modular design facilitates the replacement of the plastic skids in as little as 2 minutes. This results in a lower total cost of ownership as Ecolite pallets are built to withstand decades of normal use in ASRS systems.

Anti-Slip Features: Ecolite’s patented anti-slip features, including ‘Sure Foot Pads,’ ‘Load Lock Washers,’ ‘Load Lock Plugs,’ and ‘Tine Lock Plugs,’ address the four main areas of slippage in ASRS systems. See diagram below.

Fire Safety: The metal deck of the ER64.2 serves as a fire break, inherently making it fire retardant. This feature translates into cost savings on fire prevention systems and insurance for system operators.

With its robust but lightweight construction, Ecolite pallets withstand the demands of powerful ASRS machinery, providing dimensional stability and locational accuracy without compromising performance. These features collectively contribute to reduced operational interruptions, lower maintenance requirements, increased throughput, and an overall reduction in the Total Cost of Business.

Ecolite pallets are cost competitive with plastic pallets of comparable load bearing specifications. Choose Ecolite for ASRS-equipped supply chains and unlock a substantial return on investment. www.ecolitepallets.com

Comments are closed.