The growing trend across industry to improve efficiency and productivity by gathering and analysing data is putting large amounts of information in the hands of management. While lots of data is good, and areas for improvement are often identified through this process, sometimes it is simple and clear information that is needed on the factory floor to improve efficiency and productivity, especially as the demands on each worker’s time is increasing.

Although most machines that frequently need operator attention have a tower light indicating red, amber and green for the overall health of the machine / process, the operator still has to approach the machine to read an information display, in order to find out why the tower light is not on green (indicating that everything is good).

Although most machines that frequently need operator attention have a tower light indicating red, amber and green for the overall health of the machine / process, the operator still has to approach the machine to read an information display, in order to find out why the tower light is not on green (indicating that everything is good).

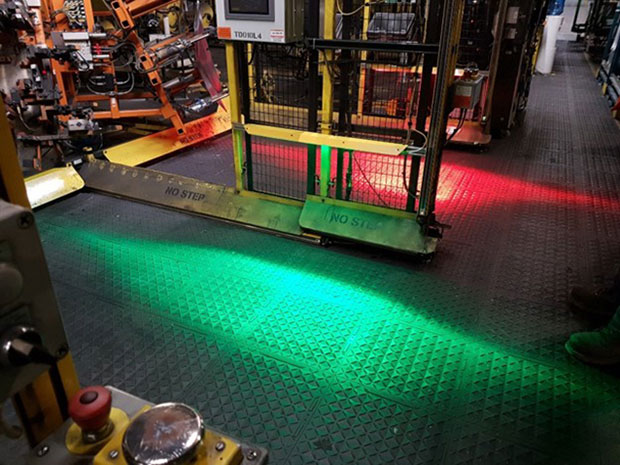

The operator could be far more efficient and productive if the most common conditions affecting a machine could be identified from a distance.

Turck Banner’s programmable lighting is only limited by your imagination. (Well almost.)

What is a programmable light?

The Banner Pro range consists of Strip lights, Tower lights, Touch buttons, Indicators and Pick-to-Light.

Colours and other features that can be programmed in the lights blur the distinction between these types. Strip lights that would normally be just for illumination can now be used as tower lights or indicators. A push button that would normally require multiple indicators to show different states and responses can now be achieved with a pro illuminated touch button.

Pro lights are able to display 12 standard colours, or any colour using RGB values. They can display animations like flashing, rotation, light intensity and multiple colours in one segment. Segments of a light can be controlled individually, in groups or the whole indicator.

Pro Lights are programmed using the free Pro Editor software, where the configuration is stored within the light and activated using the hard-wired connections, or via a PLC choosing the pre-programmed configurations. They can also be controlled dynamically via IO-Link or Modbus for greater flexibility, allowing the programmer to prioritise indication states within a single light. For example, in a normal running mode, the indicator could show fill levels of multiple bins and production speeds on different segments or areas of a light. However, if the machine stops, the majority of those indications become irrelevant at which time the whole light alternates between red and whatever colour is used to indicate the empty bin.

A tower light or indicator has to be able to give a clear and unmistakeable message. If a light uses a coloured lens illuminated by a white light, it is often difficult to distinguish between the indicator being on or off, especially in bright ambient light. All Turck Banner lights use a white lens illuminated by coloured LEDs. This ensures that when the indicator is off there is no possibility of it being mistaken for being on.

While the cost of a Pro light is a little higher than a non-programmable light, the cost saving can be far greater due to a reduction in the number of spares, stock holding and eliminating multiple lights or combinations of indicators and switches.

Banner have been using and developing LEDs and industrial housings for their photoelectric sensor products for over 50 years. The same technology is applied to their lighting products, which ensures reliability and a product life of over 50,000 hours, even in the harshest conditions. All housings are designed for industry, with a protection class of IP65 to IP69K. The robustness of the LED lighting products allows them to be positioned much closer to harsh environments than alternative light sources, providing greater illumination or reducing the power consumption for an equal amount of illumination.

Although the flexibility of programmable lights are perfect for some, others may not want to programme their light. For these customers we have all of the standard configurations. We can provide a light that is either configured or pre-programmed to the customer’s specification, and for larger quantities we can provide kits, bulk packing and even custom branding.

Whatever the customer’s choice, either Pro or non-programmable, Turck Banner can provide the solution and reduce their costs, while also helping with their sustainability objectives.

Comments are closed.