Leading global provider of materials handling solutions, Interroll, has launched its energy efficient High-Performance Crossbelt Sorter.

The new High-Performance Crossbelt Sorter MX 025H, offers an increased conveying speed of up to 2.5 m/s, enabling throughput rates of up to 20,000 conveyed goods per hour. At the same time, the High-Performance Crossbelt Sorter MX 025H is able to transport goods weighing up to 50 kg. In addition, the width of the carriers has been increased by an impressive 50 percent. This means an enormous gain in flexibility when sorting goods of different dimensions.

Other improvements include replacing the drive chain with a rubber belt. This negates the need for lubrication and offers simpler maintenance should the belt need changing. However, extensive testing indicates that the belt will last for several years, even in the case of 24/7 operations.

Hilton Campbell, managing director of Interroll UK, explained: “The MX 025H High-Performance Crossbelt Sorter has been designed with efficiency gains and environmental benefits in mind. Without compromising on performance or functionality, we’ve increased flexibility and durability.

“Our patented mechanical design ensures accuracy and speed with fewer electrical components than a conventional crossbelt sorter, offering further cost savings and energy consumption benefits to end users over the lifetime of the machinery. We’re looking forward to sharing the MX 025H’s capabilities with the attendees of IntraLogisteX.”

The direct drive principle behind the mechanisms in the MX 025H also means that if one drive unit fails, the sorting operation can continue uninterrupted. Downtime is therefore significantly reduced as the sorter can be used right up until the point of maintenance. The sorter also operates extremely quietly – below 67 dB(A) – even at the highest throughput rates.

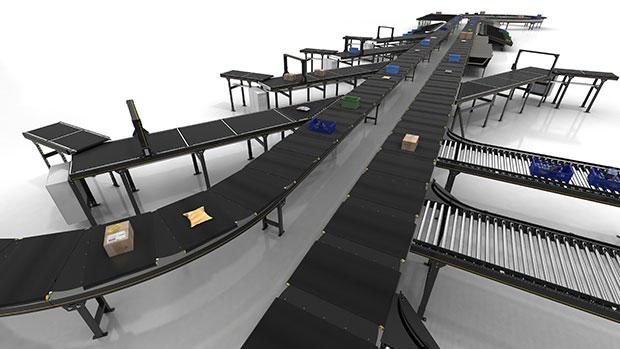

Based on Interroll’s Sorter Solution Platform, all requirements for the automatic sorting of goods weighing up to 50 kilograms can be met. The portfolio includes solutions ranging from entry-level to high-speed applications. This makes the sorters suitable for end users who are just starting to introduce automated sorting processes as well as for end users who already operate large distribution centers and distribution locations. A huge variety of goods can be sorted including boxes, parcels, maxi-letters, packaged food, mail order goods, mail order bags, polybags, clothing and more.

Approximately 500 Interroll sorters are already in use worldwide by industry leaders such as Amazon, DHL, FedEx, UPS, ASDA, Hugo Boss, Inditex (ZARA), Zalando, Great Bear, Swiss Post, Austrian Post and China Post.

Comments are closed.