Geek+, the global leader in mobile logistics robots, has released its latest solution, RoboShuttle Plus, achieving one-stop storage and picking of all types of goods and delivering higher throughput and flexibility. This marks a significant advance in the interoperability of Geek+’s various robot models and a stride towards full warehouse automation.

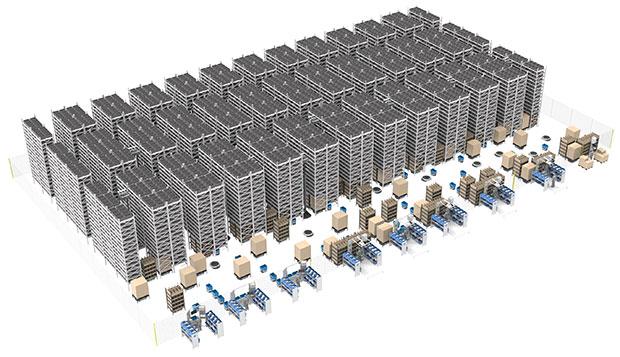

The upgraded solution fills the market gap for an all-in-one picking solution by coordinating three types of robots around one centralised workstation: RoboShuttles handle vertical storage and retrieval of totes, P40 picking robots move smaller items, and P500 and P800 robots move medium to large items.

The upgraded solution fills the market gap for an all-in-one picking solution by coordinating three types of robots around one centralised workstation: RoboShuttles handle vertical storage and retrieval of totes, P40 picking robots move smaller items, and P500 and P800 robots move medium to large items.

Hongbo Li, Chief Technology Officer at Geek+, said: “The RoboShuttle series has been one of our most successful line of solutions enabling automated height storage for warehouses, and this latest version realises the full potential of our technology as it adds more speed and higher throughput for customers. Entrusting all picking to RoboShuttle Plus allows businesses to centralise their operations and enables them to respond to business fluctuations quickly and easily.”

Geek+’s warehouse management software coordinates the actions of all robots and optimises the placement of goods in the inventory to ensure maximum efficiency and 99.99% picking accuracy. The solution makes full use of vertical warehouse space and removes the need for multi-zone operations by allowing items of all sizes to be handled by one solution at a centralised workstation.

Comments are closed.