Packaging manufacturer Allpack has launched a revolutionary stretch film called Grip® into the warehouse and logistics sector.

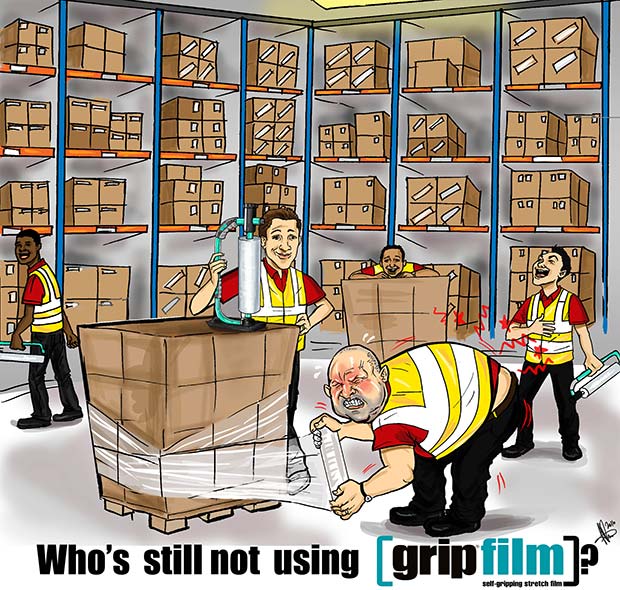

Grip® film is a self-gripping stretch wrapping system that speeds up the wrapping of pallets significantly and reduces operator strain with its unique lightweight and ergonomically designed dispenser. According to Allpack’s Head of Product Innovation, ergonomic tests showed a 74% reduction in back injury claims when trialled across 400 operators over six months.

Grip® film is a self-gripping stretch wrapping system that speeds up the wrapping of pallets significantly and reduces operator strain with its unique lightweight and ergonomically designed dispenser. According to Allpack’s Head of Product Innovation, ergonomic tests showed a 74% reduction in back injury claims when trialled across 400 operators over six months.

The Grip® dispenser is made from an ultra-light carbon fibre material weighing less than 800 grams, 4 times lighter than any other applicator. The film itself is pre-stretched to 480 metres, ensuring it can be just ‘laid-on’ to the pallet rather than stretching it manually.

Grip® is used and endorsed by some of the UK’s most recognised household names, Home Bargains, DB Schenker, DHL, PepsiCo and McCain Foods to name a few. One company successfully avoided a substantial HSE fine as a result of implementing corrective action through implementation of Grip® Film.

The H&S Manager at Nivea, the leading skin care brand, says: “We approached Allpack with a safety concern when wrapping pallets manually, as part of a distribution operation. Allpack responded immediately, with a trusted solution, showing us previous success of the GRIP film dispenser.

“Our workforce trialled the equipment, and found it to be not only safer, but easier and less time consuming for them. Allpack representatives then came in and trained all of the workforce, even on night shift. Both safety and productivity have improved after full implementation of the GRIP dispenser.”

Allpack’s Sales Director, Marcus Clarke, says: “Whilst the development of the Grip® system came out of workplace H&S issues relating to back injuries and other operational dangers like having to walk backwards with traditional palletwrap, there are also significant commercial benefits from moving to the Grip® stretch film system.

“Wrapping a standard pallet with Grip® film uses 73 grammes of plastic compared to 121 grammes of traditional film, a 39% reduction in plastic.

“Grip® film is good for the environment and offers good cost savings on pallet wrapping operations.”

Other features of the Grip® dispenser include a robust skid plate, allowing the user to wrap the film close to the floor level to add extra load support, a simple speed thread for adjusting the tension, negating the need for fiddly film loading, and a unique rapid roll-change process, with a notched film-core and twist-lock retention mechanism.

A new version recently introduced is the Grip® Magnet Dispenser, which cleverly incorporates two magnets enabling the dispenser to be attached to a racking stanchion or any metal surface.

It can also be attached to a forklift truck ensuring it is always at hand for the order picker and solves the annoyance of dispensers being run over and damaged. This version is still under 1kg in weight.

Warehouse Manager Steve G at DHL comments: “We were having issues with breakages and discovered Grip® film to be a different product altogether. Straightaway we saw a reduction in damages, and a reduction in workforce sickness absence.”

If you would like to trial the Grip® system in your operation, contact Allpack for a free demo on 01922 472400 or email sales@allpack.uk.com.

Comments are closed.