Things change fast in today’s world, so coming up with ways of achieving manpower savings, improving safety or increasing capacity could make that critical difference. Building a solid and efficient materials handling operation doesn’t start with buying a truck – instead, the process should always begin with a careful analysis of your needs and current operation so that you can see what is being done well and what can be improved. When planning a new warehouse, or thinking about making changes to an existing one, it’s possible to use some basic figures about the operation to make an analysis of how effective the solution will be. Logistics analysis can increase uptime and boost efficiency in these challenging environments.

Figures like the trucks’ speed, the rack heights in the warehouse and rough travel distances can give you an estimation of how the operation will look. However, this result will only ever be a fairly approximate estimation – and there’s a good chance it could be missing crucial details that lead you to the wrong conclusions.

Figures like the trucks’ speed, the rack heights in the warehouse and rough travel distances can give you an estimation of how the operation will look. However, this result will only ever be a fairly approximate estimation – and there’s a good chance it could be missing crucial details that lead you to the wrong conclusions.

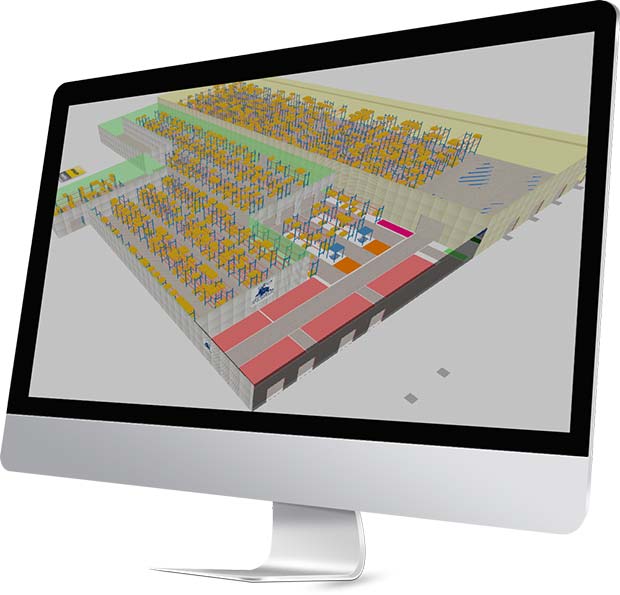

‘Static’ calculations on fixed, unchanging figures like these should be avoided, especially when simulation software is available. Static calculations can only offer a snapshot of the operation. A simulation, on the other hand, takes into account the huge amount of variables which can affect a materials handling operation.

For example, if you wanted to find out the time needed for a truck to drive to a rack, retrieve a pallet, and take it to the dispatch area, your calculation may involve the truck’s average driving speed, lift speed, and distance to the pallet location. A simulation would give a more realistic picture, as it would take into account other vital details by simulating the actual route — details such as truck and pedestrian traffic, the acceleration parameters of the specific truck and manoeuvring needed along the route, and even the time taken for the driver to get on and off the truck, if it’s relevant.

A simulation is dynamic and changing, just like a real materials handling operation – not flat and fixed, like a calculation. So if you’re serious about boosting efficiency and creating the most rational operation possible, it is essential to use simulation software.

Helping your business prosper

We can help you bring costs down and make your challenges easier to deal with – not only with simulation analysis, but with equipment, and a range of material handling solutions:

•Service support and coverage that maximises uptime

•Account management that reports KPIs and supports strategy

•Cost control strategies

•Contract suitability to meet business demands

•Relevant fleet management equipment

If you want to learn more about the benefits of simulation, or need help with your materials handling operation, why not give us a call now on 01844 215501 to arrange for a member of our team to visit? Or find out more at unicarrierseurope.com/uk/Logistics-Analyser.

Comments are closed.