Engineered heating solutions can answer the challenges of installations that aren’t suitable for off-the-shelf products. They offer the flexibility required to meet the heating needs of ‘problem’ buildings, explains Joe Kiernan of Reznor UK Ltd.

Consultants and contractors are faced with constantly changing requirements for heating in the commercial and industrial H&V market – including ever more stringent Building Regulations. End-users rightly demand perfection for their investment and will be quick to complain if comfort levels fall short of expectation.

Compromising on heating systems is never an option. So when a building presents exceptional challenges – because of unusual layout, conservation requirements or other out-of-the-ordinary features – an off-the-shelf heating product is rarely the most appropriate solution.

A correctly designed, well-engineered solution, tailored precisely to the application, will always answer the heating needs of the building and its occupants. In Reznor’s experience, bespoke heating systems are specified more often than ever before. One reason for this may be the pressure to achieve energy efficiency ratings.

Modern heating installations must optimise fuel efficiency, produce lower greenhouse gas emissions, operate very effectively and quietly, and in some cases provide both heating and ventilation or summer cooling.

Investing in high efficiency heating equipment costs less in both capital and ongoing running costs, as well as being eligible for 100% Enhanced Capital Allowances up to one year from installation.

Engineered solutions – the benefits

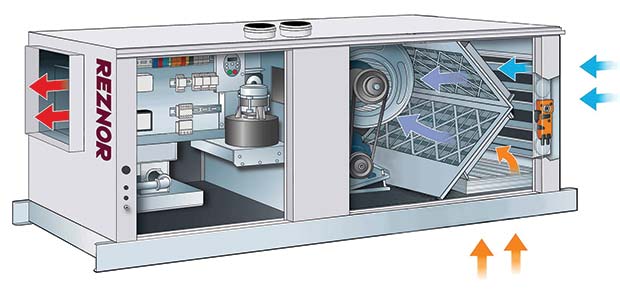

Engineered heating systems can include heaters complete with a range of optional extras such as filters, modulating burners, dampers, discharge heads, cooling coils, re-circulation fans and so on, to meet the precise comfort levels required.

Additionally, a Reznor solution will include the provision of other critical information, subject to the requirements of the building, such as heat loss calculations, schematic drawings, flue design, the suitability of types of control equipment and the optimum positioning for the equipment.

Heating system design will also take account of any constraints or obstacles imposed by the building, ensuring the correct layout for the installation.

In the case of Reznor engineered solutions, effective partnership support for consulting engineers, ensuring the H&V requirements of the project are handled smoothly and efficiently, is part of the package. All routine queries about the heating installation can be handled with nominated contractors without having to refer to the consultants.

A Tailored Solution

Most heating specifications are fairly straightforward however some engineered solutions require heaters to be tailored for specific purposes, which was the case for clothing company ASOS. A unique heating system was required to guarantee a consistently comfortable working environment for staff in ASOS’s 52,000 sq ft warehouse in Hemel Hempstead.

As with all multi level mezzanine systems there were concerns that heat from the lower level would rise to the top causing the top level to be too warm, whilst leaving the bottom level under heated.

Reznor were able to provide the ideal solution using their innovative Air Mix system. This unusual solution demonstrates the flexibility that an engineered solution can bring when a heating specification is unusually complex or out of the ordinary. In all engineered solutions, Reznor applies expertise and technical capability to develop a tailored and wholly innovative approach to heating.

Phone: 01303 259141

Email: reznorsales@nordyne.com

Web: www.reznor.co.uk

Twitter: @ReznorUK

Facebook: Reznor

LinkedIn: Reznor UK Ltd

Comments are closed.