Welcome to episode fiftyseven in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world. In this episode we’re up to 1971, the year Britain’s coinage went decimal.

Welcome to episode fiftyseven in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world. In this episode we’re up to 1971, the year Britain’s coinage went decimal.

Our writer is James Brindley, an acknowledged authority on fork lift trucks. James’s distinguished career has involved engineering and management roles with BT Rolatruc and serving as a Director of the Fork Lift Truck Association, before he set up the National Fork Truck Heritage Centre in 2004 as Britain’s first such collection open to the public.

The Heritage Centre continues to need your support in 2011, and if you or your company would like to help in any way, you can contact James on the number below. Now sit back and enjoy the latest part of this fascinating series.

Episode 57: 1971 – Britain’s coinage goes decimal, Caterpillar opens UK lift truck plant

The Komatsu Company provided a first for itself during the beginning of 1971 with a battery powered reach truck. Known as the FBR 10 R1 it had a lift capacity of 2000lb and was a stand in machine. The reach function was obtained using a pantograph on the fork carriage. Another first was supplied by the Japanese Company Nichiyu. Its basic product was released onto the Japanese market during 1970 as the first Automated Guide Vehicle (AGV). and its speed was controlled by an SCR panel that did not require contactors. This innovative pallet mover was also launched onto the wider markets as the World’s first ever AGV during the 1971 International Materials Handling Exhibitions.

Here in Britain the news was also bright with the formation of a new manufacturing partnership with America. The first lift trucks produced by Caterpillar in the UK were completed at the end of January at their new plant in Leicester. Models produced at this time were the T 30/40/50 and 60 which were powered by the 52 hp petrol engine. These models were approximately the same as the equivalent models produced in the USA although slightly different in external appearance. All models were available with a choice of either hydrostatic or manual transmission.

This year also signalled the formation of a new British forklift truck company by the civil engineering group Hudswell Badger. The original forklift called the “Total Interceptor” was made by Total Hydraulics during 1970 and then sold on to the Swansea Jig and Tool Company. After its further sale to the Hudswell Badger Group the truck was given a mechanical facelift and renamed the “Hudswell Total”. Although the product incorporated minor alterations the concept of modular design was still kept. The machine was special in that it had no conventional chassis and consisted of three main units. The front section contained the mast and carriage, driving wheels, ball type hydraulic motors and the hydraulic pump. The mid-section was designed for the engine with a choice of diesel, LPG or petrol fuel. Either choice of power unit was mounted on a self-supporting stress-sump. This particular part was the only link to the rear section which contained the steering wheels and counterweight.

In addition to the new manufacturers there were also new machines from the established British sector with Harbilt, Coventry Climax and Shelvoke and Drewry making significant progress. Coventry Climax filled a gap in their DA range with the 3000lb capacity 30 DA fitted with a Land Rover engine and Shelvoke and Drewry extended its range with three models to its “Defiant” range. The new machines of 4,000lb, 5,000lb and 6,000lb were all offered with a choice of Hydrostatic or Torque Converter drive. One important fact from this company was that during 1970 its forklift sales doubled with 50% of the units made being exported.

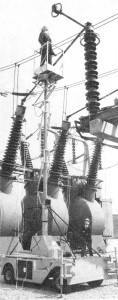

As the final contribution for this year the Harbilt Company of Market Harborough produced a dual purpose machine for use by the CEGB in the maintenance of its sub-stations. It was designed especially to lift and attach earthing cables to its overhead equipment so that servicing could be carried out. The Harbilt “Homer” was able to raise and fit these earthing clips up to a height of 7.75 metres by remote control from a distance of 9 metres. When earthing had been completed the machine doubled as a mobile access platform.

By James Brindley, Director, National Fork Truck Heritage Centre.

To be continued…

Comments are closed.