SKYShades UK is the name for a new business formed by Dr Robert Carpenter of Inside2Outside Ltd and SKYShades International, the exclusive UK marketers of the innovative SKYShades coverings technology since 2008. But the story goes back much longer.

SKYShades UK is the name for a new business formed by Dr Robert Carpenter of Inside2Outside Ltd and SKYShades International, the exclusive UK marketers of the innovative SKYShades coverings technology since 2008. But the story goes back much longer.

Dr Robert Carpenter, founder and Managing Director of Inside2Outside and now MD of SKYShades UK, has been involved with creating Advanced Tensile Membrane Structures since 1991, starting out installing temporary aluminium frame structures and from there becoming an expert in the provision of tensile membrane structures, a form of architecture in which the fabric is stretched taut across a frame to form a roof.

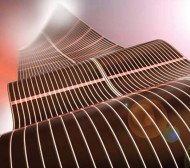

SKYShades International are the Australia-based global leaders in developing and supplying shade and tension membrane structures. Their latest development is to integrate into their fabric roofs an innovative solar technology known as Tensile Fabric Photovoltaics (Tensile PV). These solar panels are very light, don’t need reinforced roofs to bear the increased load, and can be retrofitted into existing structures.

Considerable energy savings are achievable by using solar panels incorporated into the tensile membrane structure to generate electrical energy, which makes a significant difference to the bottom line. Dr Robert Carpenter, Managing Director of SKYShades UK, spoke to Warehouse & Logistics News.

Warehouse & Logistics News – Robert, what is your role in the SKYShades UK business day to day? Do you get involved in devising solutions for customers?

Yes, very much so. We have a very competent team, but the more complex the installations, the more interested I become.

WLN – How big are the structures you supply?

Size doesn’t really matter. We believe anyone looking at installing any size of PV product should give Tensile PV serious consideration. It is by far the most versatile and sustainable photovoltaic product suitable for use in the UK. From 20m2 to 20 acres, the returns generated by Tensile PV can far exceed those from more traditional solid photovoltaic panels. However, installations below 20m2 are really getting too small to be viable, without strong secondary end uses to justify them.

WLN – How do you sum up your proposition for customers in warehousing and logistics?

We give your building a secondary use that proves or reinforces your sustainable credentials, while providing significant savings of income.

WLN – What kind of field sales force do you have to market your structures?

We have an existing sales force of 15, but want to achieve a distribution network of 100 teams in the next 12 months.

We have an existing sales force of 15, but want to achieve a distribution network of 100 teams in the next 12 months.

WLN – Are your structures attached to buildings or free standing?

Our canopies, shelters and covered walkways are either attached to existing buildings or grounded with posts. Usually, our structures are fixed to a modern warehouse. However, where the existing roof is fragile, we cover the whole building with an independent “second skin”. This technique can also be used instead of re-roofing an old or leaky roof – where our tensile PV provides a waterproof layer that harvests the sun’s power over the whole roof – whether facing south or north.

WLN – How does your relationship work with SKYshades in Australia?

They are there when we need them. SKYShades International has its manufacturing base in Sri Lanka and principal design teams there and in Australia. Smaller, standard structures are manufactured here, but larger more complex structures such as sports stadia and airport buildings tend to be designed, manufactured and installed from these two bases.

WLN – How big are SKYShades as a business in Australia and round the world? What kinds of operations are their structures used to protect?

SKYShades International is probably the world’s largest tensile membrane manufacturing company. Tensile membrane shade structures are much more prolific in Australia and other sunbelt countries across the world, where there is much more sunlight than here and protection from overexposure to UV is crucial, and SKYShades’ canopies are widely used in car parks, shopping malls, sports venues and many public places.

Tensile membrane structures are used for virtually any type of building, pretty much anywhere in the world. A tensile structure is lightweight by design, using much less materials then conventional techniques. This produces significant cost savings and possibly more importantly, tensile structures are much more sustainably manufactured and installed than conventional structures. Particularly now using Tensile PV as a Building Integrated PV, the environmental benefits of using SKYShades Structures are extremely significant. From school playgrounds to sports stadia, through warehouse structures, temporary and permanent, anyone considering building a structure with a view to sustainability or cost savings should be looking at a SKYShades solution.

WLN – Where are the structures made for UK customers?

Our standard structures are designed here and manufactured either here or Sri Lanka, depending how busy we are. The company’s international design teams design the more complex structures.

Our standard structures are designed here and manufactured either here or Sri Lanka, depending how busy we are. The company’s international design teams design the more complex structures.

WLN – What is the story behind your new solar panels?

We cover large areas with tensile membranes. For probably the last 20 years, I’ve been looking for a way to combine these areas with a means of harnessing the sun’s power in the form of electricity. About 18 months ago, manufacturing carbon-based instead of Silicon-based solar photovoltaic panels looked like becoming reality, so we saw our chance to capture this opportunity. Carbon-based photovoltaic panels’ manufacture is very environmentally friendly: their carbon footprint is much less than solid panels, even before they start being used.

WLN – How different are your solar panels to other solar panels?

Most UK solar panels are Silicon-based solid panels, covered in glass. Our panels are lightweight and flexible. Tensile PV technology works anywhere it can collect light. The panels don’t rely on being at optimal angles to the sun. This means we can cover whole roofs, whatever way they face, even north facing walls if required, and our panels are much more suitable than solid panels for the relatively low light levels in the UK. Being lightweight, our products’ structural impact on any roof is minimal, enabling us to cover whole roofs without additional structural designs or engineering to support glass panels. These qualities mean Tensile PV can be retrofitted onto virtually any warehouse roof, whatever size and however fragile and whichever way it is facing, at any location. It is far more versatile and much more environmentally friendly than solid PV panels.

WLN – Where are your solar panels made?

The components are sourced from the optimal locations at the time of manufacture. Final assembly is usually here.

WLN – What sizes do these panels come in?

It depends on the size of roof. For standard modern UK warehouse roofs, the panel width will be 4-6m, to fit the standard bay size of the roof trusses. Being tensile membrane-based, this comes on a roll and is cut to length.

WLN – Are you offering the Tensile Fabric Photovoltaics to all your customers?

Yes, our first move is to attract a number of high profile pilot projects to launch the Tensile PV into the UK. We would look to work with these pilot sites to demonstrate the actual amount of power produced by each structure compared to its location. We plan to have pilots in place in early 2011.

WLN – How can customers use your technology to reduce their electricity consumption?

Our product cannot reduce electricity consumption, but it does make the electricity consumed much more environmentally friendly and effectively far cheaper than buying power from the grid directly. Exactly how this is done depends upon the customer’s requirements. Our Tensile PV produces DC power. Under present legislation, this must be converted to AC to qualify for the government’s Feed-In-Tariffs. The government pays an incentive for any electricity our product produces – whatever the customer does with the power. If the customer uses this power to run their factory, they will not have to buy that power from the grid. If the customer doesn’t use the power produced by Tensile PV, the grid purchases that power from the customer. So in effect the customer is paid twice for any power Tensile PV structures produce.

Our product cannot reduce electricity consumption, but it does make the electricity consumed much more environmentally friendly and effectively far cheaper than buying power from the grid directly. Exactly how this is done depends upon the customer’s requirements. Our Tensile PV produces DC power. Under present legislation, this must be converted to AC to qualify for the government’s Feed-In-Tariffs. The government pays an incentive for any electricity our product produces – whatever the customer does with the power. If the customer uses this power to run their factory, they will not have to buy that power from the grid. If the customer doesn’t use the power produced by Tensile PV, the grid purchases that power from the customer. So in effect the customer is paid twice for any power Tensile PV structures produce.

WLN – Do you offer the electrical hardware and cabling to take the output from the photovoltaic panels to wherever it is used?

We offer the complete installation. We also offer regular (usually annually) inspections and maintenance to ensure continued performance.

WLN – Can you retrofit your panels to existing roofs?

Yes, we can. This is a very economic way to deploy Tensile PV. The PV membrane is so lightweight and versatile it can be attached to the whole roof, usually without needing costly structural surveying or structural strengthening. Where the existing roof is fragile, to avoid any damage to the roof, we cover the space above the roof.

WLN – How easy are these panels to install?

Installation is quick and in most cases very straightforward. Where a ground mounted tensile membrane structure is installed with integrated Tensile PV, installation starts with the footings. The frame is then installed followed by the Tensile PV, which is tensioned into place to ensure the longevity of the whole product.

WLN – Do your panels need to be facing in a particular direction?

No, they don’t. Tensile Fabric Photovoltaics can be installed even on north facing roofs, as they don’t need direct sunlight to generate electricity, just light.

WLN – Do you need special installers?

Yes, you do. SKYShades UK provides a service to cover the complete installation, commissioning and maintenance of an installation where required. But we’re happy to work with the customer where they can bring their own skills to the installation.

WLN – How easy are these panels to clean and maintain?

Very, when you know how! We offer – and recommend – an annual inspection and maintenance service. It is often claimed that Solar Photovoltaic installations do not require any maintenance. We strongly believe this is not the case. All installations benefit from regular maintenance and cleaning, principally to inspect and check those parts of the installation (the accompanying electronics) that don’t last as long as the Tensile PV. These are the same parts that would be likely to go wrong on standard installations.

Very, when you know how! We offer – and recommend – an annual inspection and maintenance service. It is often claimed that Solar Photovoltaic installations do not require any maintenance. We strongly believe this is not the case. All installations benefit from regular maintenance and cleaning, principally to inspect and check those parts of the installation (the accompanying electronics) that don’t last as long as the Tensile PV. These are the same parts that would be likely to go wrong on standard installations.

WLN – Are these systems weatherproof?

Yes – additionally, a Tensile PV membrane over a whole roof would add significantly to the weatherproofness of the building as a whole. The Tensile PV effectively acts as an extra watertight layer over the existing roof – this can also be used for further insulation or for ventilation controls of the whole structure.

WLN – We don’t get that much direct sunlight here. Do these panels generate enough electricity in “normal” British daylight for industrial use?

Yes. Tensile PV is much more suited to the UK climate than solid glass panels.

WLN – What kinds of power ratings do they have?

The power generation depends on the area of land, or the size of roof. The larger the area covered, the greater the power generated. A 100kWp system needs an area of about 1500m2. An average home needs 2.5kWp to run all its electrics for a year.

WLN – Can you tell us about the organisations that have used them and the kinds of energy savings they have achieved?

The largest installations of Tensile PV are currently in Australia. A 5mWp power rating requires about 20 acres, compared with around 35acres for solid solar panel systems.

WLN – What kinds of energy savings are possible with your systems?

This depends upon the installation’s size – a 5MWp installation will produce about 4GWh of power in an average year. Over 25 years the 5mWp installation would generate an income of around £113m, or around £4.5m per year, for an initial £12-15m investment.

This depends upon the installation’s size – a 5MWp installation will produce about 4GWh of power in an average year. Over 25 years the 5mWp installation would generate an income of around £113m, or around £4.5m per year, for an initial £12-15m investment.

WLN – What‘s these panels’ typical working lifetime?

For MCS certification, products must have a 25-year lifespan and be working at about 80% efficiency at end of life.

WLN – Do you advise companies on how to use this technology to their best advantage?

Absolutely. But we recognise that we cannot know everything about every installation, and it’s important to work with the customer to develop a system that is most likely to meet his needs today and into the future.

WLN – Do you offer a solar solution specifically for the warehouse sector, so people can generate electricity on their roofs?

Yes, we offer a solar solution designed for the ‘W&L’ sector. Tensile PV is probably the most efficient and rewarding way of utilising the roof space of the UK’s many and varied warehouse roofs. Interest has been very significant from this sector, not only those who want to cover their roofs, but those wanting to maximise their income potential from micro generation by providing Tensile PV roofs to their carparks and other open spaces. Covering such areas has the additional benefit of providing weather protection for users of the areas.

WLN – Do you have a checklist for potential end users to see if their operations are suitable for either your canopies or the photovoltaic technology?

Does your company use a building with a roof? Do you have any outside spaces within your operation? If the answer is yes to either, your company would probably benefit from Tensile PV technology.

WLN – What are the steps involved in getting one of your solutions? How quickly can you quote? How long from go ahead to go live?

We can provide a lot of information by telephone, and can usually give ballpark examples from there in a matter of days. We are very happy to visit to collect information to give a more detailed feasibility study; we usually visit within two weeks. On acceptance of this, we provide a formal quotation prior to proceeding. Once the order is received, delivery and installation currently start in about six weeks. This timeframe is very likely to lengthen dramatically. If you would like to qualify for the greatest Feed-In-Tariffs for the next 25 years (installation before April 2012), it would be hard to guarantee this unless your order is received before July 2011. This observation is taken from the German example, where they recently reduced their Feed-In-Tariffs.

WLN – What do your solutions cost? Do you offer finance packages?

Our installations pay for themselves over the life of the current Feed-In- Tariffs. An installation needn’t cost anything at all: using a ‘rent a roof’ scheme, you would just receive an income from a managed Tensile PV array on the roof. Greater benefit would be gained by investing in the system, and a range of finance options are available. There are probably as many solutions as potential customers.

WLN – What industrial standards are your technologies approved to?

All our products conform to the relevant requirements of the Government’s Feed-In-Tariff scheme, The tensile membrane structures and electrical installations meet the appropriate codes and guidelines.

WLN – What do you see as the main drivers of adoption of your technology in the ‘W&L’ sector?

The government are offering significant financial incentives at the moment, but the most significant driver depends upon the individual user. There is a growing sector where sustainability and Carbon footprint are of primary importance, driven often by their customers, but also by government directives. This applies both to Tensile PV and the canopies themselves, as they are extremely efficient means of covering large areas of space.

WLN – Where do you see SKYShades UK going from here?

We would like to see every warehouse roof covered by Tensile PV. This would make a very significant contribution to the security of the country’s energy supply and to supplying its needs now and increasingly in the future.

SKYShades UK

Tel: 01480 498297

2 Comments

Can you show any pictures of UK installations?

I am keen to know more about the tensile PV. We wish to incorporate these in our project and need to give a proposal to our clients.

We wish to know how these will be fixed on our PVC fabric for tensile structures. The standard Panel sizes and their electrical output. The standard warranties for these units and indicative costing. We would appreciate a prompt reply from your end on this subject.