The British Frozen Food Federation (BFFF) has published research which could help firms save thousands of pounds in their annual energy bills, as well as reducing their CO2 emissions.

The British Frozen Food Federation (BFFF) has published research which could help firms save thousands of pounds in their annual energy bills, as well as reducing their CO2 emissions.

The report will help companies in the frozen food industry to better understand the importance of using data loggers to improve temperature management.

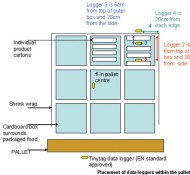

The investigation researched the storage temperatures of a group of companies in the frozen food industry. The researchers used over 60 Tinytag Transit data loggers to monitor temperatures at various stages in the supply chain.

Eight areas for improvement were identified, five of which relied on the temperature data loggers.

These included:

•Avoiding over-cooling in blast freezers

•Reducing the temperature difference between air and refrigerant

•Making seasonal adjustments of the evaporating temperature

•Raising cold-store air temperature when a cold store was running unnecessarily low

•Avoiding air- temperature fluctuations by establishing steady control at the warmest possible temperature

Most supply chain companies could implement at least a few of the suggested measures with minimal outlay. Some might require a certain degree of capital investment, particularly in older premises, however as the research indicates this investment could be offset by consequent energy savings.

Visit www.Tinytag.info or call 01243 813000 for more information on how you can save energy and reduce your CO2 emissions using Tinytag Data Loggers.

GEMINI DATA LOGGERS UK LTD TEL: 01243 813000 EMAIL: info@tinytag.info or info@geminidataloggers.com www.tinytag.info

Comments are closed.