The logistics planning consultancy LPC International has been helping logistics operations here and around the world put effective operating systems and procedures in place for 25 years. These systems have helped LPC’s clients steer their way successfully through various downturns and recessions since then. Over the years, LPC has developed a number of highly effective techniques to help logistics operations not only survive economic downturns but emerge stronger and fitter. LPC International senior consultant Ian Nicholls spoke to Warehouse & Logistics News.

The logistics planning consultancy LPC International has been helping logistics operations here and around the world put effective operating systems and procedures in place for 25 years. These systems have helped LPC’s clients steer their way successfully through various downturns and recessions since then. Over the years, LPC has developed a number of highly effective techniques to help logistics operations not only survive economic downturns but emerge stronger and fitter. LPC International senior consultant Ian Nicholls spoke to Warehouse & Logistics News.

Warehouse & Logistics News – Where and when was LPC International set up, and who by? Are they still involved in the business? Who owns the business now?

Robert Williams, LPC’s founder and sole owner, started the business in 1984. He sold it in May 2007 to a management buyout team comprising David Hayward-Browne, Jason Tindley and Graeme Smith.

WLN – How big is LPC now in turnover and staff? How many offices do you have, in how many countries?

WLN – How big is LPC now in turnover and staff? How many offices do you have, in how many countries?

We don’t disclose our turnover but there are currently 20 in-house consultants and external associates. We have the one office in Cirencester, in Gloucestershire, and are a medium-sized consultancy by industry standards.

WLN – How much of your business is in the UK?

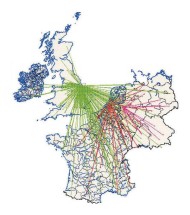

The proportion varies year to year but as a rue of thumb 40% is UK and 60% abroad, primarily North America, the Middle East and South Africa. Many of the leads come through our network of people we have worked for over the years.

WLN – How much of your business is for trans-national clients working from the UK across several countries?

WLN – How much of your business is for trans-national clients working from the UK across several countries?

The UK-based businesses whose overseas operations we work for tend to have autonomous country operations. For instance, Unilever’s HQ is in the UK but we work directly for their South African operation.

WLN – What size operations are your clients? Can you name any companies you work for?

The opportunity varies from a single depot to a network, and from a warehouse of 15,000 square foot to 1 million plus. We can work with any size operation to develop a solution: our designs are scalable around consistent design principles.

The companies we work for in the UK include Dixons Group, Sainsbury’s, Co-op Group, all retail operations. Overseas clients include Unilever’s manufacturing operations in various countries and Loblaw, Canada’s biggest food and drink retailer. We have clients in manufacturing, retail, grocery, leisure and technology: in the UK we also work on projects for the NHS.

WLN – What kind of work do you do for your clients?

Our work typically starts with a health check: a depot or logistics network is not performing as required, or it may be a new build, which we design and project manage, or we provide a combination of both, for companies with a series of depots. We also optimise routing and scheduling, and can offer advice about any functional area in warehousing and logistics operations.

WLN – Even in good times, the UK and European logistics sector is traditionally very competitive, providing high levels of customer service and working on tight profit margins. What’s your prognosis for the effects the current recession will have on the logistics industry?

WLN – Even in good times, the UK and European logistics sector is traditionally very competitive, providing high levels of customer service and working on tight profit margins. What’s your prognosis for the effects the current recession will have on the logistics industry?

We expect to see a continuation of the recent consolidation among large and medium 3PLs. Many companies get involved in warehousing and transportation: as they develop the progression could be to more logistics outsourcing, based on detailed advice from a consultancy like LPC.

Warehouse and transport is a non-core business area for the typical client: we can help them either run it better or outsource it.

WLN – When would you advise a client to outsource?

We advise them to outsource when current capacities are exceeded, bottlenecks appear, processes can’t cope or where costs need to be reduced, and reconfiguring isn’t the answer.

WLN – When the smoke clears after the recession, will there be fewer third party logistics companies left standing?

WLN – When the smoke clears after the recession, will there be fewer third party logistics companies left standing?

If anything, I’d say the opposite. We predict more opportunities for logistics companies and consultancies as big customers realise they are not the logistics experts they thought they were and they do not have the capacity or infrastructure they need. These companies will be wondering how they can reduce their enormous logistics costs.

WLN – How can logistics operations plan for this recession? If they haven’t done so already, is it too late to start now?

It’s not too late but the earlier you engage, the better. People should be talking to consultants and logistics professionals about how to reduce their logistics costs. The natural scenario is “we’ve gone as far as we can and we need help”: they’ve got to be honest and admit their limitations. It should happen at board level, with the finance director and MD driving the decision based on the costs of logistics in the business. Established businesses have shaved the cost of their goods to a minimum, but growing companies need to do it. Though any solutions should be designed to allow companies to take competitive advantage when the recession ends.

WLN – In summary, what can logistics operations do to drive operating costs down without affecting their level of service?

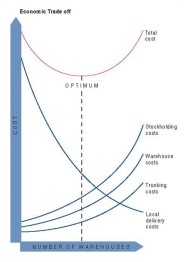

Rigorous examination of inventory levels, warehousing facilities operations and transport operations is, best started by means of an audit of costs and unit cost performance across warehousing and transport operations, the audit being linked a review of operating procedures and resources.

Identify the high cost areas, particularly in relation to inventory, the use of space, labour, and vehicles. Then focus on those high costs, to find out why they are high, and to determine how they can be reduced. Don’t worry about the lower cost areas at the preliminary stage, as the potential savings and benefits will be less. Think “outside the box” and be prepared to consider radical solutions.

WLN – With respect, aren’t these measures standard ‘best practice,’ something the logistics companies can work out for themselves?

WLN – With respect, aren’t these measures standard ‘best practice,’ something the logistics companies can work out for themselves?

They are in theory, but consultants offer an objective vision. We’re talking about companies with an in-house logistics operation, that may have promoted someone into the logistics function from another discipline – best practice is developing all the time. In the ‘90s a company may have had a logistics health check, but ten years on the business and people have changed. Ideally, you should review every three years.

WLN – What do you bring to the party?

We bring impartiality, no historical politics and no agenda. Our core set of skills is interchangeable and you can turn it on and off. We have no links to particular suppliers. Suppliers of IT, racking and materials handling equipment offer consultancy, but it’s not impartial – we provide totally neutral guidance on what is best for the client.

We judge each operation on its merits and work from a template, designed to customers’ needs.

WLN – Are there many logistics planning consultancies out there? What sets you apart?

In the UK there are 30-40 one-man bands; in the medium sector where we are there are a dozen firms; and then there are the bigger consultancies, who cover the majority of the supply chain. If you cover everything, you can dissipate your focus: LPC supports customers’ selection of hardware and software – we have high-level IT knowledge, but we are focused on the supply chain. LPC’s ultimate attraction is that we don’t just design solutions, we implement them.

WLN – What’s your role in the business from day to day? What were you doing before?

WLN – What’s your role in the business from day to day? What were you doing before?

My role is primarily business development and building the pipeline of live projects. I also project manage other consultants. I was previously with Swisslog (UK) Ltd as Business Development Manager.

WLN – What are the steps in reviewing a company’s logistics operations and arriving at a solution?

First we gather information and data: we look at current operations and forward projections. We understand the ‘as is’ and how it functions, and from there benchmark the process to ensure it complies with customers’ understanding. We produce concept studies, with three or four options to go forward, then determine the preferred concept study and confirm the processes will work. It could be large scale, a new hub, or small-scale, micro level, running a function better.

The next stage is implementation – a new build, a retrofit or tweaking methods. Our role could take a couple of days or 12 months. We agree a precise budget and narrow scope of design then go from there.

WLN – What does a typical LPC solution for a client entail?

Solutions fall into two groups – new facilities requiring large, long-term projections and strategic focus, or re-engineering existing operations on a smaller basis to offer value.

WLN – If a company reading this is worried about their state of health, how quickly can you step in?

Depends on the appropriate resource, we can respond in a few days with an initial meeting and scoping. Our structure allows us to bring in flexible resources, including analysts and CAD people: we don’t use agency staff. We can get someone there within a week and do the analysis in a few days. For a simple process, we can recommend a concept in a few weeks.

WLN – Presumably most of your work results in the client’s improved operational health. Have you ever had a client that was clearly failing, and you couldn’t restore them to fitness?

If the core business is failing, no amount of supply chain work will help. If the logistics arm is failing but the rest is healthy there’s always the chance to save it. You may need to reorganise or move a distribution centre, but it’s not the end of the world.

WLN – How quickly can you deliver results?

Broadly, we can complete reconfiguring and implementation in a month or so but an elaborate large-scale concept design can take a year or more.

WLN – Can you tell us about some of your recent projects?

We worked on a 1 million square foot DC supporting a series of factories in South Africa, for a company in the food and beverage sector. We have re-engineered an Internet retailer’s warehouse to improve output and reduce cost. We’re supporting the move to a new generation of distribution centres and regional distribution centres for Loblaws in Canada. The existing processes simply weren’t working. We introduced a new flow concept to the Canadian market, going from stocked warehouses to a flow through basis. It’s been familiar in the UK for over 20 years but it’s new to North America, and is an area where UK consultants are subject matter experts!

WLN – What’s been LPC’s biggest project to date? Do you publish case studies?

Our biggest project to date is re-engineering the supply chain for Loblaws. The largest DC we have worked on is for Unilever in Durban. You can find case studies for both these projects and others on our web site.

WLN – Do you sell the computer analysis and modelling software that you use to solve your clients’ problems as an application in its own right?

We don’t – much of what we offer is based on experience and expertise which you can’t package as an application.

WLN – As part of your solutions, you recommend people invest in particular warehouse management IT and storage and handling equipment. Do you get involved in implementing these solutions, ie procuring and supplying the applications and equipment you recommend?

We don’t do any purchasing – that’s down to our customers. We advise on WMS, forklifts and storage and racking. We produce performance specifications and tender documents, and advise customers on what to look for from vendors.

We assist with implementation and commissioning – we have civil and mechanical engineering expertise in house. On occasions, we have been the lead project manager, doing all build activities.

WLN – Do you have links to any particular vendors of applications or equipment?

We have no historical links with vendors, but we know pretty well who’s out there.

WLN – What industry standards do you work to? Are you accredited to any particular standards?

We produce designs in accordance with all relevant British Standards and European materials handling standards. As a company, we have a Total Quality Management system in place internally.

WLN – Are you members of any industry bodies?

We are business partners to the CILT and honorary advisers to UKWA.

WLN – Have you won any awards for excellence or other achievement?

Our results are acknowledged as part of the team on the projects we work on. Within the last year, our design for the distribution centre for Woolworths Pty (South Africa) won a SAPOA award for innovative excellence in property development design.

WLN – What do you see as the biggest external factors that you and your clients have to face?

I’d say probably the uncertainty of the current economic climate – should people invest in their logistics operations or not? Businesses are scaling back due to concerns over cash flow: everyone is contracting into their own little hole. The UK has never had a culture of long-term logistics planning, but some more astute people recognise they need to spend money on it. Some of the UK ports are developing their logistics facilities, but there is generally a contraction in in-house logistics operations, led by retailers concentrating on their core activity, which brings us back to outsourcing logistics, which is where we can help.

WLN – Finally, where do you see LPC International going from here?

Overall, I see us supporting a growing client list. The challenge is, with the recession, how can we help clients manage their warehousing and logistics in changing times? It was all about growth, but now it is all about consolidation and cost reduction. Whatever happens we will go on meeting the challenges of the market place and strengthening the supply chains to which we continue to add value.

LPC International Ltd Tel: 01285 640038 www.lpcinternational.com

Comments are closed.