Our first question this month asks about back-to-back distances and our second enquires about the tolerances on racking.

Back to Back Racking Minimum Distance

Back to Back Racking Minimum Distance

Q. I’m hoping you’re able to give me some guidance on racking. For racking that is back to back, what is the minimum distance these should be installed? Any help on this is much appreciated.

A. For the UK market the back-to-back dimension between racks is given in Appendix 4 of the SEMA Code of practice for the use of static racking and you can get a copy of this from the SEMA website www.sema.org.uk/product/code-of-practice-for-end-users-of-apr-free-complimentary-copy.

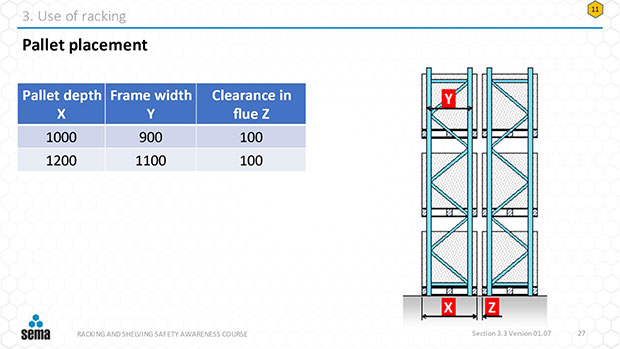

This recommends a minimum clearance of 100mm between the pallet or load (whichever sticks out the furthest). This is shown diagrammatically below;

Of course, sprinklers and other obstructions at the back of the rack sometimes mean that this dimension must be increased and this situation is treated more fully in EN15620.

Broadly similar recommendations are given in clause 6.4.4 and Annex D of EN15620:2021 “Steel static storage systems – Tolerances, deformations and clearances”, although these also deal with the situation where there are other “obstructions” at the back of the rack run.

Other national codes might have different recommendations.

Tolerances for Beam Damage

Q. I wondered if there were established guidelines / tolerances for beam damage.

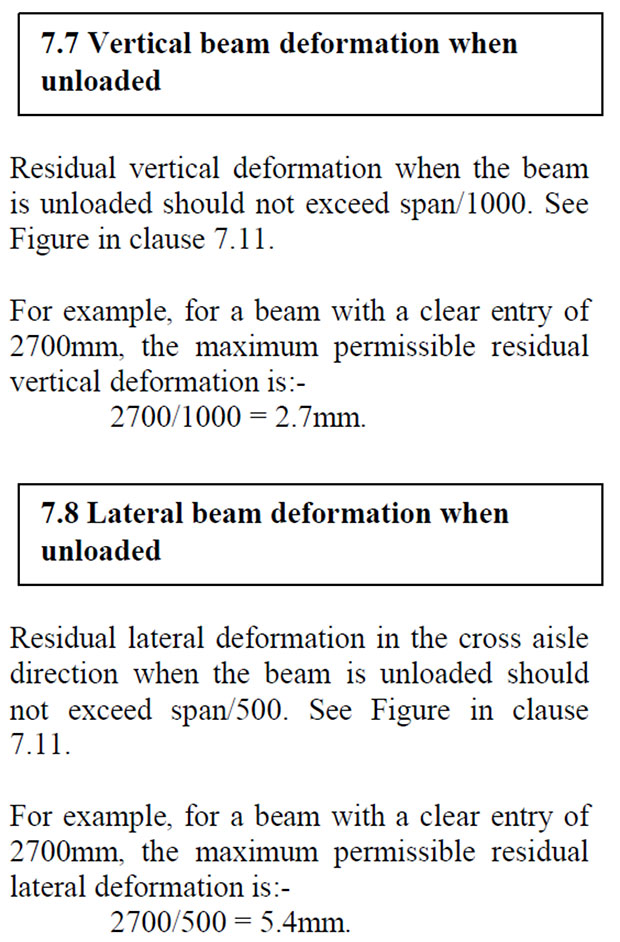

A. There are some damage assessment criteria given in the SEMA Code of practice for the use of static pallet racking. The most relevant clauses of this code are extracted below.

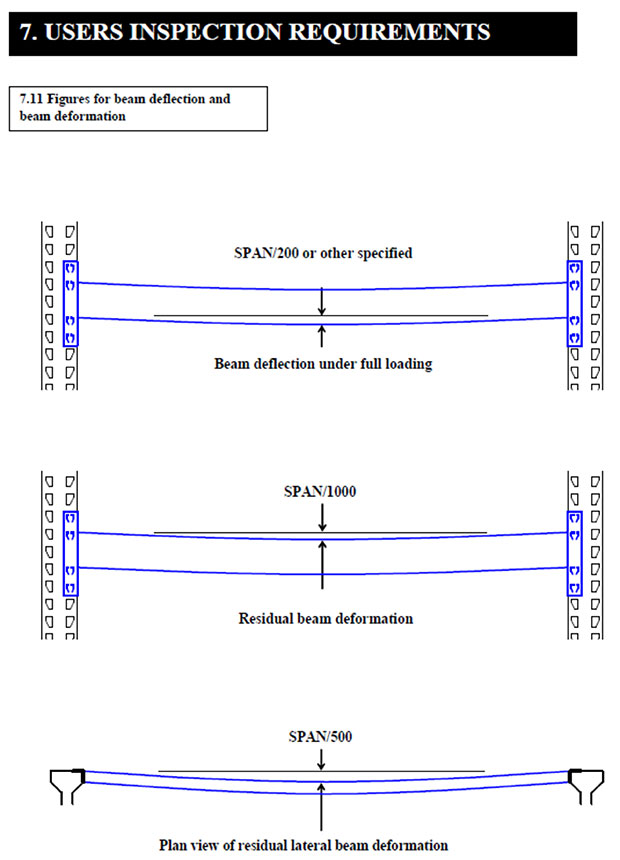

The first diagram shows the limiting vertical deflection when the beam is loaded.

The first diagram shows the limiting vertical deflection when the beam is loaded.

The second and third diagrams show the limiting deformation of the beam vertically and laterally when the beam is not loaded – if the residual deformation exceeds either of the given limits then action is required.

The second and third diagrams show the limiting deformation of the beam vertically and laterally when the beam is not loaded – if the residual deformation exceeds either of the given limits then action is required.

SEMA Rack Safety Awareness Inspection Courses

SEMA runs a one-day safety course on Rack Safety Awareness and Inspection. These courses are aimed at end users, giving an in-depth look at the need for inspections, how to conduct an assessment and what actions to take when this is completed.

SEMA Approved Rack Inspectors Qualification

This qualification is aimed at professionals who conduct rack surveys as an integral and significant part of their duties. It involves delegates in undertaking an in-depth SEMA Course, together with an examination and practical assessment. CPD will be an important part of the qualification, demonstrating to end users that SEMA Approved Inspectors maintain a high professional standard.

SEMA Publications

SEMA has 26 publications in stock – Codes of Practice, ‘Guides’ and European documents – all of which are available to purchase online.

For further information visit our website, www.sema.org.uk

Comments are closed.