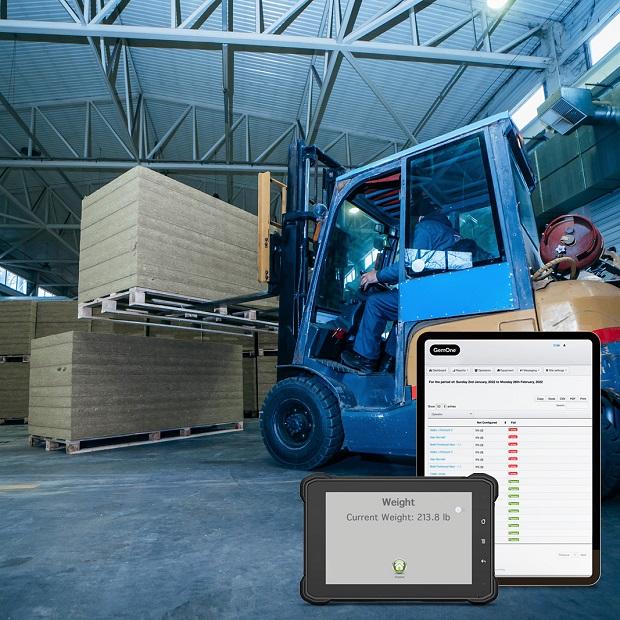

In today’s fast-paced material handling industry, efficiency, accuracy, and safety are of utmost importance. To meet these demands, GemOne has introduced Sapphire, a cutting-edge telematics solution that offers a range of advanced features tailored specifically for the industry.

One of the standout features of Sapphire is its innovative load sensor, which offers a multitude of benefits that have the potential to transform material handling operations. Here are five of those benefits:

One of the standout features of Sapphire is its innovative load sensor, which offers a multitude of benefits that have the potential to transform material handling operations. Here are five of those benefits:

- Overload Prevention

One significant benefit of the load sensor technology is overload prevention.

By setting thresholds for load capacity, operators can be notified when they exceed the safe limits.

This proactive notification system helps prevent dangerous situations related to the overloading of forklifts, thereby enhancing safety in the workplace.

This proactive notification system helps prevent dangerous situations related to the overloading of forklifts, thereby enhancing safety in the workplace.

Moreover, by avoiding overloading, the machine is protected in the long term, resulting in reduced equipment maintenance, improved efficiency, and overall cost savings.

- Enhanced Safety Measures

Safety is a primary concern in the material handling industry, where mishaps can lead to injuries, property damage, and costly legal liabilities.

Sapphire’s load sensor feature significantly contributes to enhanced safety measures.

The load sensor provides real-time feedback, alerting operators when they exceed safe weight limits, ensuring that they take necessary precautions to avoid potential hazards.

GemOne creates modern telematics solutions to help create safer work environments in and around your warehouse; find out how much safer your workplace could be with telematics here by downloading our free checklist.

- Optimised Efficiency and Productivity

Efficiency and productivity are crucial factors in material handling operations.

GemOne’s load sensor optimises both.

Operators can avoid unnecessary trips by optimising their load capacity to the safe limits set for their machine and business needs, with the certainty that they are not overloading their machine.

In this way, they can reduce downtime and increase their overall operational efficiency.

- Preventive Maintenance and Equipment Longevity

Excessive strain caused by overloading can accelerate wear and tear on material handling equipment, resulting in frequent breakdowns, downtime, and increased maintenance costs.

Sapphire’s load sensors aid in preventive maintenance by monitoring weight thresholds and ensuring that operators operate within safe limits. By preventing equipment overload and damage, businesses can extend the longevity of their assets, minimise repair costs, and reduce unplanned downtime.

Well maintained equipment is a key component to creating a safe warehouse environment: find out how safe your warehouse is by taking a look at GemOne’s free checklist.

- Compliance with Regulations and Standards

The material handling industry is subject to various regulations and standards concerning weight restrictions, load limits, and occupational safety. Failure to comply with these regulations can result in penalties, legal consequences, and reputational damage.

Sapphire’s load sensor function assists companies in meeting these compliance requirements by providing real-time alerts when limits are exceeded. This feature ensures that businesses can operate within the legal framework and maintain a high level of safety and professionalism.

How Safe is Your Warehouse?

GemOne’s Sapphire telematics solution and its new load sensor feature bring a new level of safety and efficiency to the material handling industry. By enhancing safety measures, optimising productivity, aiding preventive maintenance, and ensuring compliance with regulations, Sapphire’s load sensor is ensuring businesses in material handling can make time and cost savings related to safety, efficiency, and maintenance.

How safe is your material handling warehouse? Grab GemOne’s free safety checklist now to see how technology can make your workplace safer.

Comments are closed.