According to recent analysis, almost 100 million ft.² of additional warehouse space will be required in the next 2 years to keep pace with the growth of online retail. Ongoing supply chain problems have also led to retailer stockpiling, and supermarkets seeking additional warehouse space are experiencing major problems finding suitable sites due to record demand.

Space is therefore undoubtedly a very valuable commodity, and “improving not moving” can be the key to unlocking space, increasing productivity and avoiding extra financial outlay. It makes sense to use every inch of available capacity to maximum effect, as building, buying or leasing new facilities, if at all possible nowadays, is costly and disruptive.

Space is therefore undoubtedly a very valuable commodity, and “improving not moving” can be the key to unlocking space, increasing productivity and avoiding extra financial outlay. It makes sense to use every inch of available capacity to maximum effect, as building, buying or leasing new facilities, if at all possible nowadays, is costly and disruptive.

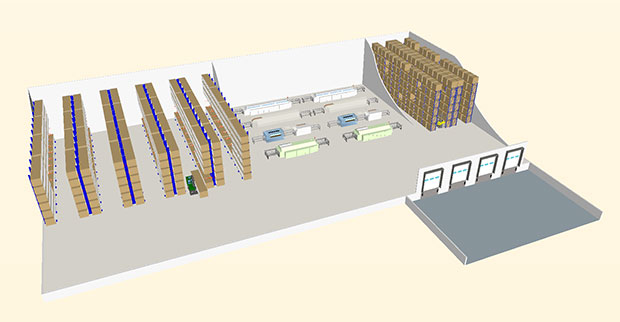

The best approach for space optimisation is to get the experts involved. As well as supplying a wide range of forklifts and materials handling solutions to over 85 countries, the Irish manufacturer Combilift has over 2 decades of experience in warehouse design and material flow analysis. Its dedicated team of design engineers create free of charge and no obligation layouts and simulations which clearly illustrate the potential space and time savings that can be achieved using the company’s products. They can show for example how reconfiguring aisle widths to work with articulated forklifts such as the Aisle Master can bring about a doubling of storage space in any given area compared to the use of reach trucks. As well as operating in 1.6m aisles, Aisle Masters have the highest reach of any articulated truck, up to 15 metres, so can work within high bay racking to exploit all vertical space. Combilift’s CEO and Co-Founder Martin McVicar: “It will cost you nothing to contact us – but could save you thousands! And looking to the future, our solutions can bring a more sustainable model to our customers’ business. If they are saving space they are reducing their carbon footprint too.”

Comments are closed.