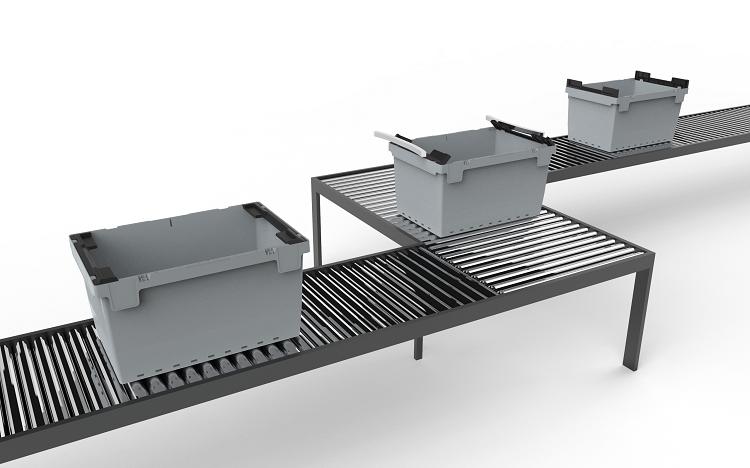

The Omnimax is an omnichannel container that can be used throughout the whole supply chain, from working with automation systems to maximise picking efficiency in the warehouse, to increasing vehicle fill during transport to the store and for deliveries to the end customer. With various automation features and a simple innovative design to increase ergonomics for manual users, this product provides significant benefit for each touch point within supply chain and is the ideal transport solution for retail, click & collect and last mile delivery applications.

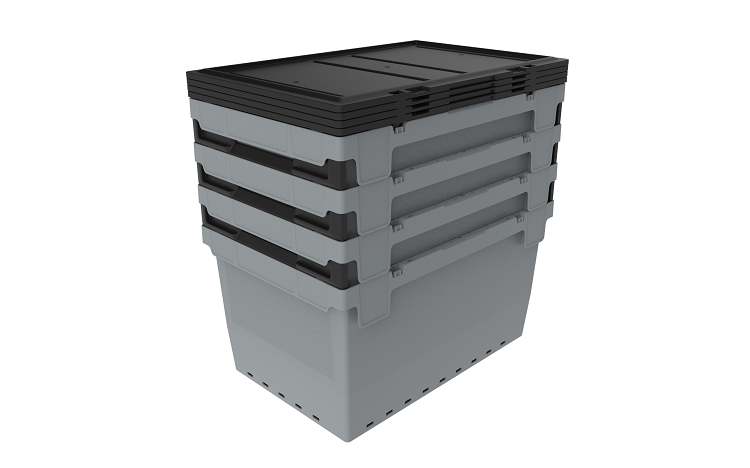

Its automation-friendly bail arm system is designed to facilitate stacking operations, reducing the need for complex robotics and human interaction, therefore significantly reducing the cost of implementation. This allows for easy handling during stacking operations; containers can be stacked easily during order picking, without the need for a lid. If used for home delivery, the Omnimax does have an optional lid available to help protect the load during transportation and maintain the packaging aesthetics for the end customer.

Its automation-friendly bail arm system is designed to facilitate stacking operations, reducing the need for complex robotics and human interaction, therefore significantly reducing the cost of implementation. This allows for easy handling during stacking operations; containers can be stacked easily during order picking, without the need for a lid. If used for home delivery, the Omnimax does have an optional lid available to help protect the load during transportation and maintain the packaging aesthetics for the end customer.

Thanks to its versatility, this container combines the features and benefits of an automated container with the high volume and return efficiencies of transport packaging. It can be implemented throughout the whole supply chain, increasing efficiency and productivity throughout.

Thanks to its versatility, this container combines the features and benefits of an automated container with the high volume and return efficiencies of transport packaging. It can be implemented throughout the whole supply chain, increasing efficiency and productivity throughout.

Available in 4 different heights, the Omnimax provides the largest usable volume on the market, offering maximum litterage of 52.4 (270mm), 62 (320mm), 69 (360mm) and 79 (400mm). Its average increased volume capacity of 7%, not only increases the vehicle’s fill during transport but also reduces waste and costs. With an 80mm nesting pitch, the Omnimax also boasts maximum return efficiencies in comparison to other nesting totes.

Available in 4 different heights, the Omnimax provides the largest usable volume on the market, offering maximum litterage of 52.4 (270mm), 62 (320mm), 69 (360mm) and 79 (400mm). Its average increased volume capacity of 7%, not only increases the vehicle’s fill during transport but also reduces waste and costs. With an 80mm nesting pitch, the Omnimax also boasts maximum return efficiencies in comparison to other nesting totes.

In accordance with FM Global regulations, the Omnimax can also be manufactured with drainage holes to allow water to drain away in the event of a fire. The offset position of the holes reduces errors during laser identification, making it perfectly compatible with automated systems.

In accordance with FM Global regulations, the Omnimax can also be manufactured with drainage holes to allow water to drain away in the event of a fire. The offset position of the holes reduces errors during laser identification, making it perfectly compatible with automated systems.

The easy picking lid sits on a hinge but then opens on an easy release, increasing ergonomics when picking while maintaining cover from dust. When the Omnimax is used in conjunction with the Loadhog Pally & Lid system it facilitates transport and eliminates double handling.

With the rise of e-commerce sales over the last years (from 13.8% in 2019 to 19.6% in 2021 worldwide), retailers have had to focus on click & collect applications and last mile deliveries. The efficiency of these operational processes has therefore become a priority and businesses are looking for the appropriate packaging solutions to meet these new expectations. The Omnimax is the answer to this rising demand and appears as the future of retail logistics.

Comments are closed.