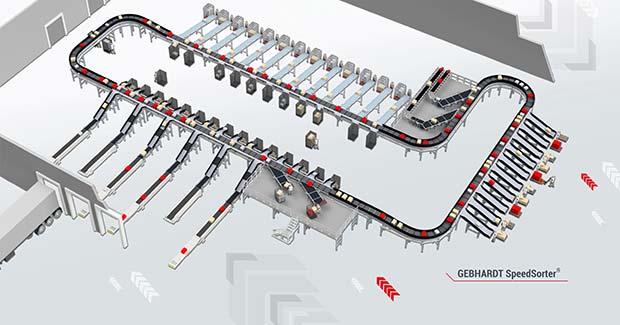

The GEBHARDT Intralogistics Group has launched a fully automated, horizontal, and smart sorting system based on the principle “mechanical meets digital”. The GEBHARDT SpeedSorter® is the perfect solution for a wide range of conveyed goods due to its modular design, high system performance, ease of maintenance and high availability. Moreover, it impresses with digital components for Intralogistics 4.0.

Due to the growing demands for online sales services and the increasing e- commerce sector, manual sorting processes are more often replaced by automated concepts. GEBHARDT recognised this potential and developed a product which optimises the sorting processes based on numerous innovative and digital features.

Due to the growing demands for online sales services and the increasing e- commerce sector, manual sorting processes are more often replaced by automated concepts. GEBHARDT recognised this potential and developed a product which optimises the sorting processes based on numerous innovative and digital features.

The GEBHARDT SpeedSorter® is based on the crossbelt sorter principle, which enables a continuous material flow concept from a single source through the combination with various system components such as incoming goods, storage, order picking and dispatch. The implementation is advantageous from a business management point of view – the internal material flow can be optimised, and the available space can be used effectively. The digital functions make a lasting contribution to increasing system performance and availability.

This product innovation allows the sorting of a wide variety of conveyed goods at high speed – from clothing and letters to cartons and even food. Totes, packages, poly- and paper bags in different shapes and weights but also longer piece goods can be transported as well.

Due to precise control and the mechanical drive, the entire system is very solid and requires little maintenance. The reliability of the sorting system is ensured by condition monitoring and the associated connection to digital solutions – such as the GEBHARDT Galileo IoT® platform.

Comments are closed.