In this article we look at how the company adopted a new Kanban stock movement and replenishment system and the benefits it has brought to the company.

Main Piece:

Main Piece:

Who is SCHMIDT Technology?

Schmidt Technology is a family owned business based in the south of Germany and is a technology leader in the fields of writing instrument technology, presses for forming and joining and advanced sensor technology.

The right amount of stock required

In order to provide manufacturing with exactly the right amount of material SCHMIDT Technology must have complete transparency of the amount of material held at any time in the FIFO racks. StockSAVER makes sure that FIFO shelves never run dry, solves all of the traditional Kanban problems and renders previously required safety stocks unnecessary.

Typical Kanban problems solved

A well organised Kanban system brings many advantages to the operation but in reality does not give good transparency on the amount of stock held line-side on FIFO racks.

Do Kanban cards get lost or damaged? Does the milk-round actually collect them in a timely fashion? Questions like this often lead to increasing safety stocks held locally in order to avoid production coming to a grinding halt.

StockSAVER – the solution from WERMA

Bins in the FIFO flow racks contain the refills which are awaiting the barrels coming in from the mould shop before being worked on further. Because there is no additional WIP stock it is important to have excellent transparency of the actual content of the FIFO flow racks to prevent too much or too little stock being held there and to allow the flow of production to run smoothly.

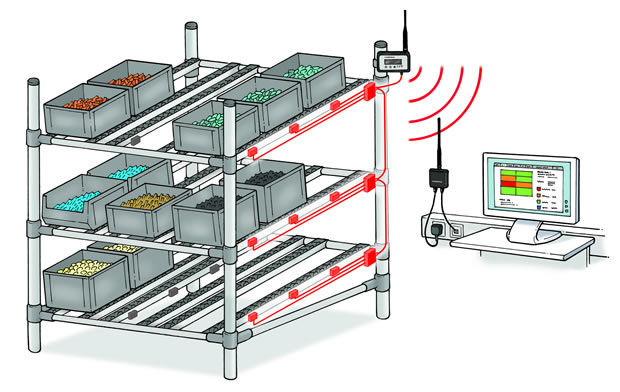

With the WERMA system, sensors fitted to the flow rack rails monitor the number of bins on the FIFO flow racks and the movement in and out and transfer this data wirelessly to the StockSAVER software. Here pre-set minimum and emergency stock levels for each component and stock location will be cross checked against the incoming movement data and automatically replenishment orders will be triggered once the emergency stock level has been reached.

Test run with WERMA‘s StockSAVER

SCHMIDT Technology fitted 17 shelves with three sensors per shelf and on one shelf installed 4 sensors. The sensors monitor the movement of the bins and transfer this data via the SmartBOX to the software wirelessly. In this way a digital version of the real-time status of the shelves is created which gives everybody a perfect overview of stock levels on the shelves In addition clear instructions are given automatically to Logistics and Planning on the replenishment requirements and priorities. Analyses and data export allow lasting improvement measures to be made to the process.

WERMA UK Ltd

Tel: 01536 486930

Comments are closed.