One of the World’s largest premium alcoholic drinks manufacturers, appointed Conveyor Systems Ltd (CSL) to provide a solution to transit case loads of flat packed Whisky cartons from a lower floor storage area up to the bottling hall before entering a carton erector and robot packer.

The main challenge to be undertaken by CSL was the limited access between floors due to the upper floor close pitch concrete beams and a crowded bottling hall. After careful planning the obvious solution was a Qimarox® Prorunner Mk1 vertical elevator which was the ideal choice due to its small footprint which kept the hole size to a minimum. The Qimarox® MK1’s other benefits includes its patented design using a high quality reinforced belt instead of chain which means it is ultra quiet, can operate at higher speeds and very low maintenance. The elevator was fitted with a motorised roller conveyor platform to allow for the automated infeed on the lower floor and outfeed transfer on the upper floor.

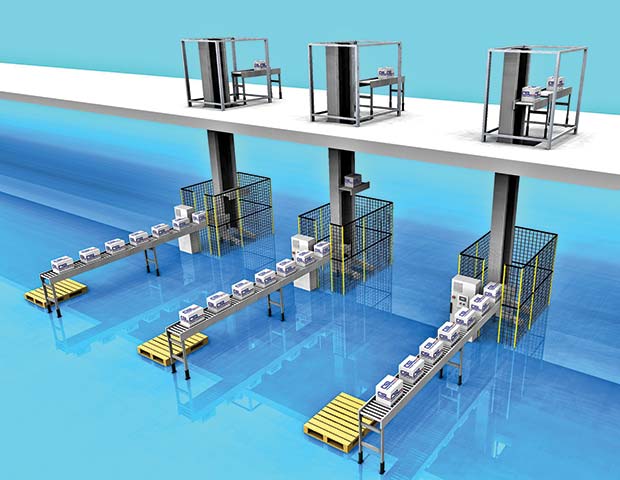

To feed into the elevators, CSL used 24v zero line pressure (ZLP) accumulation roller conveyors to singulate cases onto the elevator platform conveyor from a non contact queue the lower floor infeed conveyors are hand loaded from pallets at an ergonomically suitable height and feed…. through mesh fence safety guarding onto the lift platforms.

Once the elevator platform reaches the upper floor discharge position the case is driven onto another section of 24v non-contact roller conveyor which feeds single cases to an operator who loads the flat cartons into a newly acquired carton erector. The outfeed conveyor is fitted with a build back sensor which will stop the elevator delivering more cases if there is no space on the conveyor.

All 3 separate bottling lines have their own independent conveyor panel with a touch screen HMI for conveyor status information and fault diagnostics. To ensure the elevators are safe and CE compliant CSL fitted mesh guarding on the lower floor and stainless framed clear polycarbonate guarding in the bottling hall above. All guard doors are electronically interlocked and will close down the CSL system in the event of a door needing to be opened.

CSL provided a full turnkey project including design, supply, installation and commissioning. The Bottling Hall Projects Manager, reported “we have worked with CSL on many projects over a 19 year period and the level of expertise and service remains consistently high and never fails to impress. The latest system has made significant improvements over the previous system and has allowed us to increase productivity to meet the growing demand for our products”

CONVEYOR SYSTEMS LTD

Jim Farquhar, Sales Director

Tel: 01283 552255

Comments are closed.