At CeMAT Asia, the most important Asian trade fair for intralogistics and materials handling (27 – 30 October 2015, Shanghai), KASTO will be presenting an innovative range of products for storage of bar stock and sheet metal. The international storage technology specialists, based in Achern, Germany, will display the space-saving UNIBLOC stacking cradle system, which is noteworthy for short access times and simple material handling, in Hall W2 at Stand C1-5.

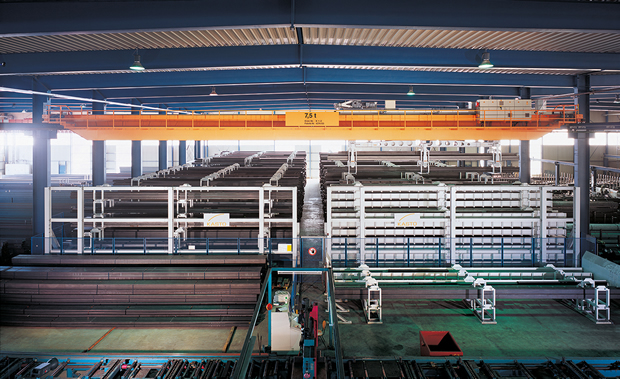

The compact UNIBLOC stacking cradle system is a cost-effective alternative for all storage needs when low to medium access frequencies are required and it does not pay to install a highly dynamic, fully automatic bar storage system. It can transport and store bar stock, sheet metal and other bulky goods with lengths of three to 24 meters. Thanks to its simple operation and handling, it provides quick access to stored goods and can restack them efficiently.

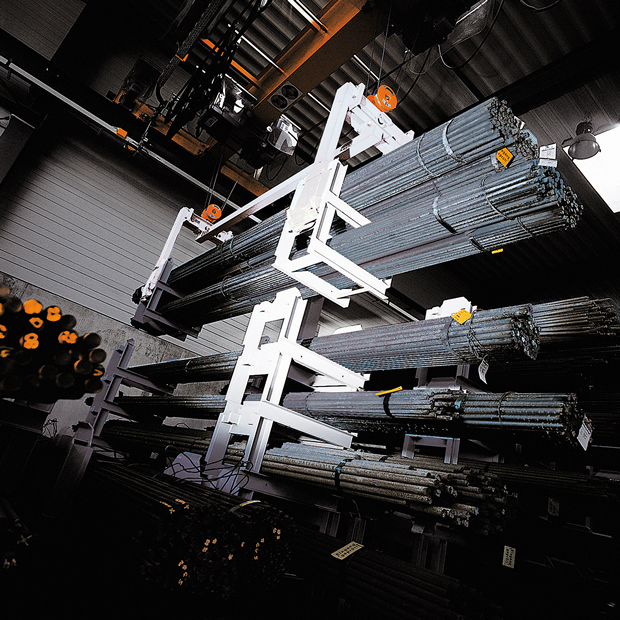

The UNIBLOC system stores pipes, bars, steel beams and other bar stock on sturdy, precision-welded cradle pairs. The cradles can be stacked on one another, making better use of the available space. A spreader beam with patented gripper arms transports and restacks up to three layers at the same time, depending on the model. This considerably accelerates turnover and reduces access times. The spreader beam can be moved manually by means of a stacker, automatically by means of a gantry crane or hoist crane, or by means of a magnetic lift.

The automatic version of the UNIBLOC storage system offers an additional advantage: the KASTO Inventory Control Computer, which manages materials and storage locations. By organising storage, restacking and removal it optimises the entire work process. Thanks to continuous inventory management, the operator is able to monitor stocks at all times and, if necessary, optimise them during unmanned shifts, for example at night.

Bars are managed individually to avoid unnecessary waste, thus reducing material costs. Manual UNIBLOC systems can also be retrofitted for automatic operation.

KASTO at CeMAT Asia: Hall W2, Stand C1-5

About KASTO:

KASTO Maschinenbau GmbH & Co. KG, based in Achern-Gamshurst, Germany, specialises in sawing and storage technology for bar stock. The company is a global leader in the manufacture and sale of metal-cutting saws and semi-automatic and automatic storage systems for bar stock and sheet metal. It is also a leading manufacturer of automatic handling systems for metal bars, sheet metal and pre-cut parts. One of Europe’s oldest family-owned companies, KASTO celebrated its 170th anniversary in 2014. In the course of its successful history it has registered 140 patents, delivered more than 140,000 sawing machines to all parts of the world and installed more than 1,700 automatic storage facilities. In addition to a branch in Schalkau, Thuringia, KASTO has subsidiaries in England, France and the USA. In 2014 the company’s roughly 670 employees achieved revenues of about 120 million euros.

Comments are closed.