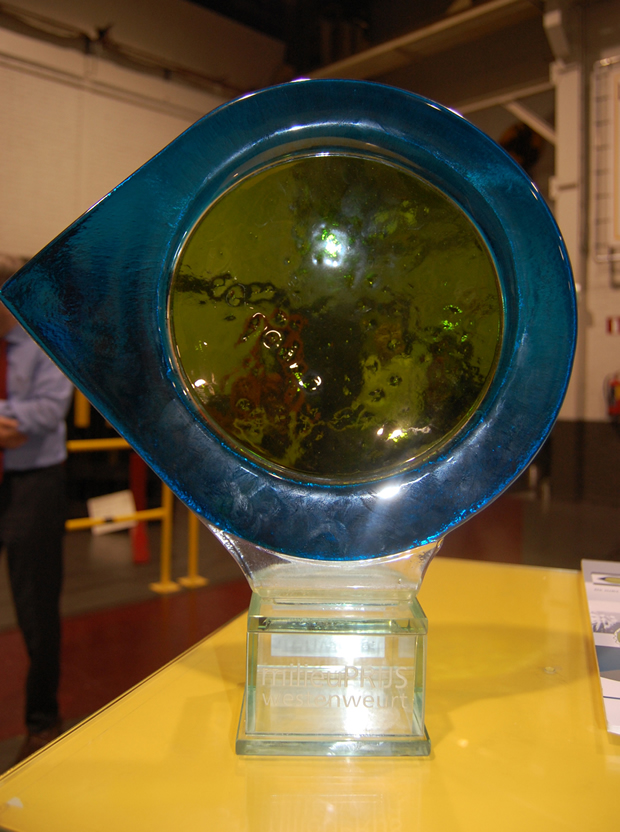

The NACCO Materials Handling Group plant in Nijmegen, The Netherlands, where Hyster Big Trucks are manufactured, has won a Dutch environmental award, Milieuprijs Westenweurt 2013.

NACCO Materials Handling B.V. beat 25 other companies to be recognised as the most environmentally friendly company in the industrial area of The Netherlands, in the east of the country.

The jury found evidence that the culture within NACCO Materials Handling B.V.helps to handle a process for a sustainable future – for the environment and also for our people explains Wim van Dam, Nijmegen Plant Manager. This is not just a marketing tool.

The five key achievements that contributed to NACCO Materials Handling B.V. winning this award were sustainable, improved processes; improved energy use; reduced fuel usage; reduced necessity to repaint vehicles; and the 93% reduced emission of Volatile Organic Compounds (VOCs).

The five key achievements that contributed to NACCO Materials Handling B.V. winning this award were sustainable, improved processes; improved energy use; reduced fuel usage; reduced necessity to repaint vehicles; and the 93% reduced emission of Volatile Organic Compounds (VOCs).

The award jury chairman Prof. Dr. B. Dankbaar (with a chair on Business Organization at the Nijmegen Radbout University) said that NACCO Materials Handling B.V. won this environmental award because of the combination of approachable environmental improvements, passionate management, sustainable policies and the consistent approach towards environmental focus in general.

The plant has also demonstrated sustainability during the economic recession, avoiding layoffs with a period of shorter working hours and part-time employment. The production line has also been enhanced, with a record 1,927 unit assembled at the NMHG Factory in 2012, beating the previous record set in 2008.

Product and process enhancements have also led to significant reduction in the emission of VOCs as well as producing products with low fuel consumption. For example, Hyster ReachStackers and Container Handlers used in ports, which are manufactured at the Nijmegen plant, are reported to deliver significantly reduced fuel emissions, as well as significant savings in fuel costs thanks, partly, to Tier 4i/Stage IIIB compliant engines.

Improvements have been made in order to prevent damage to truck parts, eliminating the need to re-spray them, contributing to reduced cost as well as being environmentally friendly.

The consumption of gas and electricity per tonne of product has also been drastically decreased. Having built a connection between the Nijmegen plant and the Nijmegen Waal river port*, in 2007 NACCO Materials Handling B.V. created a permanent dock for a barge, which enables finished Hyster Big Trucks to be shipped by barge, rather than by road. This helps to save time and money and reduce fuel consumption and CO2 emissions by eliminating the transportation of dozens of trucks at a time on the road.

The first prize was 10,000 EURO to be spent on further enhancing the plant’s sustainability and environmentally friendliness using Solar Energy Systems.

We are holding an internal competition to help decide how the money will be used says Wim. It is important to us that we include the people in this decision as they are key to the success of the company.

The Nijmegen plant also celebrated 60 years of production in 2013.

The Environmental Award West Weurt is an initiative of the municipalities of Nijmegen and Beuningen and undertakings TPN West. This year (2013) is the third time the prize has been awarded, with the title previously being awarded in 2007 and 2009.

For more information about Hyster products manufactured at the NACCO Materials Handling Group plant in Nijmegen, visit www.hyster.eu.

Comments are closed.