Atlet, one of Europe’s leading truck manufacturers and material handling experts, has been actively improving the profitability of companies in the material handling industry for over 50 years. The key to Swedish-based Atlet’s enduring success is its extensive material handling expertise and a wide range of tools that help solve customers’ internal material handling problems.

Now part of the UniCarriers Corporation, Atlet improves the profitability of its customers by offering user-oriented products, including warehouse logistics services, rental contracts, fleet management, after-sales cost a small and related services.

Now part of the UniCarriers Corporation, Atlet improves the profitability of its customers by offering user-oriented products, including warehouse logistics services, rental contracts, fleet management, after-sales cost a small and related services.

Chris Bates, National Sales Manager at Atlet UK, spoke to Warehouse & Logistics News.

Warehouse & Logistics News – First of all, Chris, as National Sales Manager at Atlet UK, what does your role involve day to day? Are you personally responsible for solutions for customers?

I have responsibility for the management and support of our UK sales force, with the ultimate duty of achieving profitable market growth. I also head up the National accounts team in order to provide direct input into customer proposals.

WLN – When was the Atlet business founded?

Atlet’s history began in 1958, when Knut Jacobsson started innovating and making trucks at home in central Gothenburg, Sweden.

WLN – When did Atlet become part of the UniCarrier Corporation?

The Jacobsson family sold the Atlet business to the Nissan Motor Company six years ago, after which Atlet’s operations were integrated into the Nissan Industrial Trucks division. In August 2012 Nissan Forklift in turn became part of UniCarriers.

WLN – Can you talk me through the UniCarrier Group and explain how you fit in?

The Japanese government has created and invested in business to develop Japan’s business interests overseas. It’s a recession-busting strategy, managed by the Innovation Network Corporation of Japan. The lion’s share of INCJ’s investment capital has gone into new technology, but a significant proportion is in materials handling. Nissan provided the industrial truck part of their business as part of their stake in the group, and so did Hitachi, with a brand called TCM. TCM as a brand is very big in Japan but less so in Europe. Atlet sits in the heart of the business, as part of Nissan Forklift.

WLN – What effect has this change of ownership had on the Atlet brand?

As far as the market is concerned, the Atlet brand remains unchanged. We have benefited from our Nissan ownership to the extent that we now have a full counterbalance range in our product portfolio and in addition, UniCarriers have started the process of identifying any product shortfall in our portfolio, based on the demands of our customers. We would therefore expect to see an even broader product range in the years ahead.

WLN – Can you talk us through the different trucks in the UK range?

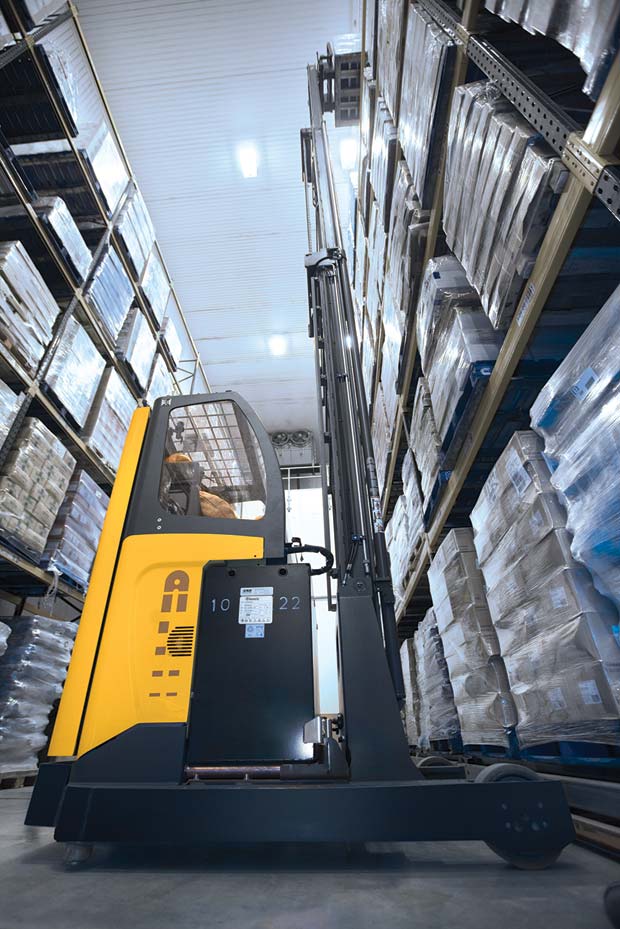

Atlet provide handling equipment designed to meet the demands of distribution and production environments. In order to meet these demands we manufacture product ranging from light duty powered pallet trucks through to heavyweight counterbalance machines and all in between. We supply equipment to specialist sectors as well, including the frozen food distribution sector and food production. The demands of UK distribution are generally for high-performance, multi-shifting hardware that is robust enough to cope with an arduous working environment, and Atlet perform extremely well in this situation.

WLN – What new trucks are you offering these days?

In early 2012 we introduced a new reach truck range, capable of lifting heavier loads higher. We also introduced a lighter capacity truck at entry level, for use in the manufacturing industry. In terms of products in the pipeline, we’ve got a new multidirectional truck for long load handling and a new generation man down narrow aisle truck, just around the corner. We will also be introducing a new generation of medium and high-level order pickers in the next 12-18 months.

WLN – How are you set up to service customers in the UK?

WLN – How are you set up to service customers in the UK?

Atlet have a direct sales and service operation which is co-ordinated from our head office in Thame in Oxfordshire. All of our sales and service personnel operate from home and provide excellent national coverage. Service support is one of the primary advantages of running Atlet equipment, and the unique manner in which we structure our service organisation provides excellent uptime and first visit fix performance for our customer’s equipment.

WLN – Do you sell through dealers and distributors?

Atlet are very much a direct sales organisation.

WLN – Do you operate independently of the Nissan dealer network?

Yes, we do. Despite being part of the same group, the Atlet offer to the marketplace focuses very much on multi-truck user operations who need to improve the efficiency of their storage and handling. Our heritage and future is based in this market sector.

WLN – Do you sell against them?

Theoretically yes, but in practice our paths don’t cross very often. The Nissan dealer group provides localised support predominantly to counterbalance users.

WLN – How would you sum up your market position?

We’re predominantly warehouse truck suppliers. Historically we weren’t involved with counterbalance trucks, but following the introduction of the Atlet Balance, we have experienced growth in this sector. Many people looking at Atlet from the outside share the opinion that we are a dedicated supplier to the distribution sector, which is true, but we now feature in manufacturing environments more than ever before. The good news is that we are able to apply space-saving and handling efficiencies in manufacturing environments as much as we are in distribution.

WLN – Do you have a different offer for the individual industry sectors?

In the warehousing and distribution sector, the emphasis has been on high reaching lift trucks, very heavy loads and frequent movements. Atlet’s always been active in this area, and our core business has been the supply of reach trucks. To meet customer demand, we have now produced reach trucks that can place 1250 kg loads up to 12.1 metres in free roaming operations. In the narrow aisle sector warehousing is going higher, but it’s only suitable for particular applications, typically high-density storage of selected products, with a consistent throughput. The key point is that people and trucks can’t pass each other in narrow aisles, and in the grocery environment you need the flexibility to have lots of people working in lots of aisles at once on a mixture of goods, which you can’t do with narrow aisle.

WLN – How do you differentiate yourselves from other truck suppliers?

WLN – How do you differentiate yourselves from other truck suppliers?

Our main point of difference, and our theme at every touchpoint, is our active interest in improving the efficiency of the customers’ storage and materials handling efficiency. We don’t train our salesmen simply to sell hardware, but to deliver materials handling solutions and expertise in how storage can enhance pick performance, and achieve the perfect balance between the best storage and pick speed.

WLN – How do you compare with other suppliers in terms of service?

The primary KPI for our service side is First Visit Fix rate. A key factor is that all our trucks share a very condensed number of unique parts – around 4,500, which is low compared to other truck suppliers, and of these 4,500 components only 20% are frequently used, which means our service engineers can carry them all on a visit.

WLN – Why would a warehouse manager turn to a fork lift supplier for guidance on storage systems?

It’s a fair question! Normally fork lift companies are concerned about hardware USPs, but we make a point of understanding the customer’s needs and the pressures they face. Only by doing this are we able to put forward equipment that is part of an overall solution designed to improve the customers operation.

WLN – Other forklift companies offer something similar. How far do you take your commitment to improving storage efficiency?

WLN – Other forklift companies offer something similar. How far do you take your commitment to improving storage efficiency?

All our salespeople are trained in storage concepts, and have access to the Atlet Logistics Analyser (ALA), which create 3D layouts of the proposed warehouse layout to simulate truck operations and provide performance forecasts. They can generate a ‘QuickSim’ – quick simulation – during a call, which as you can imagine can be very valuable input for a company that is hoping to improve storage capacity or throughput speed.

WLN – How else does Atlet help customers improve their materials handling efficiency?

We also offer a range of battery changeover systems, which we design, build and install. For multi-shifting applications, efficiency in battery change can save significant time and money throughout a year. 15 years ago Atlet chose to take all battery room design in-house in order to ensure we have a unique offer to our customers.

WLN – How did Atlet get involved in this secondary area?

We felt the mainstream battery suppliers were simply seeing battery management as a necessary function, rather than an area for improvement.

Improved battery management is part of the benefit of getting an Atlet fleet, and further justification for our claim of helping improve performance. Other battery changing systems in the open market often require a person on the spot to change batteries over; with our battery change systems, the fork lift driver can change their own reach truck batteries with no manual handling, in a quarter of the time it takes using a more mainstream system. For a fleet of as few as four reach trucks, that means no queuing and no paying wages to a dedicated member of staff and a cost justifiable payback.

WLN – There are a number of specialist independent battery management companies out there. What do you offer that they don’t?

We provide a complete turnkey solution that is entirely managed in-house. We are able to design, manufacture and install battery rooms of any size, but one of our areas of distinction is our ability to adapt to unusual space availability. We have provided installation solutions in some extremely unlikely warehouses.

WLN – Are you members of any of the UK materials handling equipment trade associations?

Atlet are members of the FSDF, UKWA, FTA and BITA.

WLN – Are you involved in developing industry standards for industrial trucks and related equipment?

We have representation on the BITA floor standards committee, not only because of our VNA demands but also because reach truck lift heights are now reaching such a point that floor flatness has to be considered for some of these as well.

WLN – With the growing emphasis on workplace safety, do you offer warehouse safety advice for customers?

We offer a risk assessment checklist that can be downloaded from our website, which has been very popular.

WLN – What is the outlook for the different sectors in the UK industrial truck market?

There certainly seems to be a large amount of consolidation taking place, and I would expect that this will continue. Our interest is to ensure that despite being part of a global international business, Atlet are able to differentiate themselves from our competitors by maintaining our materials handling approach heritage.

WLN – You’re not exhibiting at IMHX this time round. Why not?

IMHX is undoubtedly a well-organised and high-profile exhibition; the reason we have chosen not to attend is primarily because our involvement with our market extends beyond the presentation of shiny trucks. We want to do things differently in order to improve our offer to our customers, and this starts by not following the herd when it comes to exhibition marketing.

WLN – Where do you see Atlet going from here?

WLN – Where do you see Atlet going from here?

In a relatively mature market place, increased market share has to come at the expense of our competitors whilst continuing to protect our customer base. Customer retention for Atlet is extremely high (long may this continue), so my new business development team can focus on eroding our competitors’ presence in the market. Over the next six to 12 months UniCarriers will be stating their case with some extremely aggressive plans. As part of this we’ll be contacting all our primary prospects and contacts during March with reminding them we’re here and our trucks and services are available all year round, and making people aware that we have a great truck range supported by the Atlet Logistics Analyser (ALA) and our battery changing service, which delivers improved battery uptime.

The underlying message from Atlet is that the spirit and culture of our business is still the same as it was when the Jacobsson family ran it – we’re not just selling fork lift trucks, we’re here to improve the efficiency of the customer’s materials handling. We have no ambition to become a me-too contender: everything comes down to the fact that we are different from the rest of the market, and we do things the Atlet way.

Atlet Ltd

Tel: 01844 215501

Comments are closed.