SDI Group Ltd is a leading specialist in the provision of systems and solutions to the retail, e-tail, wholesale, fulfilment and e-commerce industries for all aspects of distribution centre materials handling. SDI’s expertise spans sortation systems, conveyors, automated storage and retrieval systems (ASRS), warehouse & equipment services, software systems and warehouse controls, maintenance solutions and consultancy. As both consultants and systems integrators, SDI is able to provide clients with a total logistics solution package which includes materials handling consulting, as well as design, engineering, fabrication, installation and integration services. SDI continues to innovate. On the heels of the new T1000s SDI-trolley they made for ASDA at the end of 2012, they have made further developments in sortation technology, with sales of a pusher sorter (PTU) to No-Limit in Poland, a Bombay Sorter unit and a tilt-tray-sorter to Diagma in France and a Bag sorter system to Netrada in Germany. Peter Schlüpmann, Managing Director of SDI Group Germany, spoke to Warehouse & Logistics News.

Warehouse & Logistics News – First of all, Peter, can you run through the different products and services that SDI Group provides?

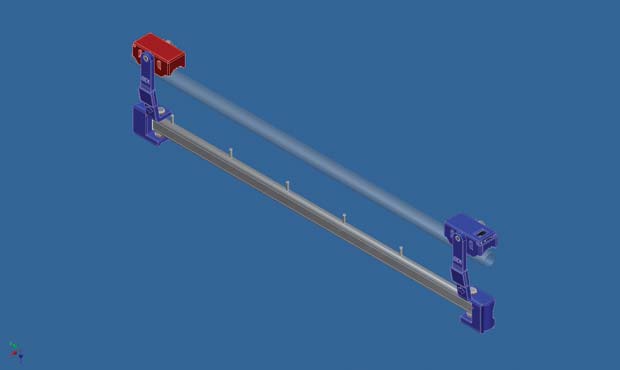

We are known as an integrator, integrating our own conveyor technology with that of other suppliers. We integrate and plan logistics centres: we provide overhead conveyors, flat goods conveyors, and bombay sorters. We’re the only people in the market for vertical and horizontal sortation. In the flat goods sortation world, we have two new sorters that have been released onto the market, a Bombay sorter with much reduced noise and a push out tray (PTU) sorter which does just that, push out items on a tray. By market standards it’s a low budget conveyor, offering a high capacity for a modest cost. The PTU will be on show at IMHX. We’ve also developed a new overhead conveyor with roller adaptors, which can handle items on hangers or in bags. This flexibility is very important for the e-commerce business, combining hangers with flat items. The unit is known in Europe as the ‘Mona Lisa’. Incidentally, we also have a component known as ‘L-VIS’, which as you can imagine we call ‘Elvis’ after Mr. Presley. It appeals to our American customers, and our US office is near Las Vegas, but that’s another story!

WLN – How do you sum up the SDI proposition?

We’re the market leader in the retail sector for overhead sortation systems, providing solutions tailored to clients’ needs.

WLN – As MD of SDI Germany, what is your role in the business day to day? Are you directly involved in developing solutions for customers?

I’m responsible for sales and admin and development of the German market, and work with our team on client projects. My background is in logistics, and I head up the planning for our business.

WLN – As a business you’re involved in retail, wholesale, fulfilment and e-commerce. How do you service the different industry sectors – do you have different teams for each one?

We have just the one team across the different parts of the business. The common thread is that all our solutions are for retail operations of different kinds.

WLN – When was SDI Group founded? Who owns it now?

SDI was founded in the 1970s. It is privately held.

WLN – Where is your global head office?

We have two divisions, one in the US, in Pacoima, California, covering the Americas and Australasia, and one in Royston, Hertfordshire, covering Europe. Our IMHX effort is coming out of the Royston office.

WLN – Are you personally involved in the UK business?

I’m not directly involved in it from day to day, but we are part of the European team, and if a UK customer needs our input we team up with them to provide it.

WLN – How does your UK business differ from your business in other countries?

In terms of our pipeline and order book, there’s plenty of business coming through. Customers in the UK are investing in new logistics facilities and extensions: it’s not as strong as it was before the financial crisis, but it’s still happening.

WLN – How do you service UK clients? Do you have a UK office and dedicated team looking after the UK?

We cover the UK from the Royston office, our strongest unit in Europe. We have a big service division in the UK, in excess of 75 people and a very strong maintenance side.

WLN – What sets SDI apart from other materials handling solutions providers? Why buy a materials handling solution from you?

We are unique in our part of the market. There are some really big logistics sites with an investment in materials handling of over £100m. Some vendors provide cranes but don’t supply sorters and overhead conveyors, which is where we come in.

WLN – Can you tell us how your consultancy service works?

We get a lot of our leads through consultancy. We talk to big customers like DHL and TNT. The market is driven by initial consultation, especially in Germany.

WLN – Do you get involved in designing brand new warehouses, or are you generally called in after the buildings have been put up?

It works both ways – sometimes customers, especially smaller ones, call us in before they commit to anything in terms of buildings.

WLN – What size companies, in what industry sectors, stand to benefit most from your solutions?

Some 90% of our business is in the garment industry and retail. Our projects vary widely in throughput and speed, which depends on the technology involved and the customer.

WLN – What exactly is the T1000s Trolley that you developed for ASDA?

The T1000s SDI-trolley was a product that we originally sourced from the US SDI business. We redesigned it with a new heavy trolley, new conveyors and line conveyors, and tailored it to ASDA’s specification. It’s extremely successful: in some areas productivity is up 300%.

WLN – Are you offering it to other retailers?

Yes, we are offering it to other customers. We have recently finalised a new contract with a large fashion retailer in the UK, where the new trolley will be installed.

WLN – Are you showing the T1000s SDI-trolley at IMHX?

The L-VIS garment hanging system will be on show at IMHX.

WLN – Can you tell us about the new sortation developments you have made in recent months?

The developments referred to in the introduction have all been in response to customer requests. SDI is known to have good capability: we have a big production area and our own plastic moulding machine. Customers always want special requirements, and we have wide experience in various areas.

The bag sorter we provided for Netrada that you mentioned in the introduction came about because the competition had developed a system along those lines but with e-commerce growing in Europe as it is, it wasn’t sufficient for the customer’s requirements.

WLN – It sounds like these news systems were developed to meet the needs of specific customers. Are you offering similar technology to other people?

Yes, we are. It’s relatively easy to adapt our systems for other customers: they’re not just designed for one company. Hence we’ve offered the ASDA system to another large fashion retailer. A lot of our business involves convincing customers to replace their old system with ours.

WLN – Let’s talk about IMHX. Are you going to be at the show yourself? Who else from SDI will be on the stand?

Yes, I will be. All country managers and key members of our European team will be there, including Gordon Smith, our CEO.

WLN – What solutions will you be demonstrating at IMHX?

We’ll be exhibiting our Pusher Tray Sorter (PTU) and a Garment Hanging demo sorter: a smaller loop and overhead sorter for hanging garments and large car components.

WLN – What new products and developments will you be showing at IMHX?

If customers at the show are interested, we’re happy to talk about other areas in which we can help. We have plenty of case studies that show our modular approach; detailing all new developments.

WLN – How important are shows like IMHX to your company and its strategy?

Trade shows are a big part of our strategy, and hugely important to us globally. We were present at 12 big shows last year across the world.

WLN – The big question: why should a busy professional from the logistics industry take a day out of the office to visit your stand?

They should come to us first because they can see our new products and second because we’re well known in our business and if they’re planning to invest in a new system, they should at least see us before they commit to anything.

WLN – With the growth of home shopping, will your offerings for customers in these areas be on show at IMHX?

Yes, they will be. It’s the same situation across Europe, high streets are not growing: the new turnover is in the Internet business. We are specialists in e-commerce fulfillment, as the Netrada solution demonstrated.

WLN – Looking at the wider picture, what do you see as the biggest pressures on users of your systems?

As I see it, the biggest pressure is the need for people to change the way they think about logistics. Traditional retailing is fine, with its huge volumes, but Internet business and the smaller orders involved call for a different approach, which is a driver for future logistics solutions, which leaves the door open to handle products in other categories and different volumes.

WLN – How are you helping customers address these pressures?

Our systems are very flexible – for instance, our flat goods sorter doesn’t care if the business is retail or e-commerce. Flexible overhead solutions are developing fast. We follow the market trend for a mix of new and old sortation technology, and offer a combination of both, providing new solutions for the new marketplace.

WLN – Finally, where do you see the market for materials handling systems like yours, and SDI Group as a business going from here?

WLN – Finally, where do you see the market for materials handling systems like yours, and SDI Group as a business going from here?

The market has improved in the last year after the financial crash. In Germany especially, there’s a really good market with a strong order pipeline. Our customers love our new solutions, and we have found plenty of good ways to integrate them into existing systems. As a company we are well prepared for the continuing growth of Internet shopping, and have a strong proposition to offer our customers.

Tel: 01763 244299

email: info.uk@sdigroup.com

Comments are closed.