Located in Monaghan, Ireland, Combilift’s materials handling portfolio combines the world-leading Combilift range of multidirectional forklifts, sideloaders and the Aisle-Master range of AC electric and LP Gas powered articulated VNA forklifts. Robert Moffett and Martin McVicar established Combilift Ltd in 1998, and it grew quickly to become the global leader in the long-load handling market. Today Combilift’s products can be found in over 70 markets worldwide.

Martin McVicar, Managing Director of Combilift Ltd, spoke to Warehouse & Logistics News.

Martin McVicar, Managing Director of Combilift Ltd, spoke to Warehouse & Logistics News.

Warehouse & Logistics News – Martin, as Managing Director, what is your role in the company day to day? Are you directly involved in developing the product range? What about talking to customers and winning orders?

I take an active and hands on role in the day-to-day running of the company. Initially an engineer by profession, I liaise closely with our design engineers and R&D department concerning product development and regulations. My genuine passion for getting our products out into the global marketplace means I spend a fair amount of time travelling to identify new markets and customers around the world. We receive a lot of visits at the factory from customers and dealers, which we actively encourage, and the feedback we get from this is invaluable. Anyone who knows me will testify to the fact that I am definitely not a “desk bound” MD! My motto is: “Customers do not beat a path to our door; we need to go to the customers.”

WLN – Aisle-Master and Combilift are two separate propositions. Can you explain each of them?

Although different when it comes to the targeted end users, both brands share the common characteristics of space saving operation, multi-functionality and versatile indoor/ outdoor operation. As customers nowadays want more from their equipment, this is one of the keys to the success of both product ranges. The Combilift is highly manoeuvrable and can replace a variety of other types of forklifts for safer, more cost effective and efficient handling of long and bulky loads. Its 4-way ability enables even extreme loads to be transported in confined spaces, which leads to substantial space savings and greatly enhanced productivity. The Aisle-Master Very Narrow Aisle forklift is a versatile VNA articulated forklift that works in extremely narrow aisles, enabling a dramatic reduction of working aisle widths in the warehouse. It can do the work of both reach and counterbalance forklifts. Both brands have a proven track record of enabling much improved productivity.

WLN – Who would be the typical customer for an Aisle-Master, and who would you recommend buys a Combilift? Do you have separate sales and technical teams?

It all depends on the application and size of load to be handled. As a rule, palletised operations are obviously best served by the narrow aisle articulated trucks, so many of our Aisle-Master customers are in the 3PL, pharmaceutical and food and drink sectors. If you are looking at moving 3m, 8m or even 20m loads of metal, PVC or timber however, you will need the long load capabilities of a Combilift. If an operation is dealing with a combination of palletised and long loads then the counterbalance design 4-way Combi-CB may be the solution. Our sales teams are trained specialists in both brands, enabling them to pinpoint the ideal model and specification for any given application.

WLN – With Combilift’s savings on storage space and Aisle-masters reducing working aisle space, do you offer customers a warehouse planning service?

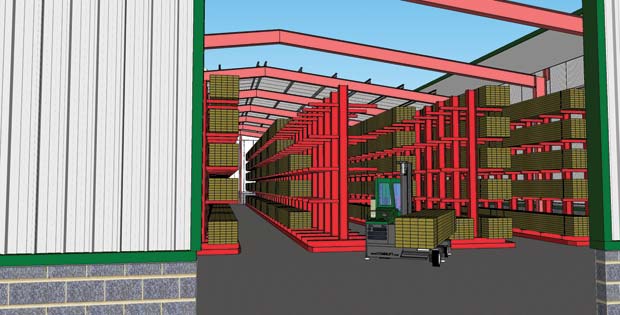

Yes we do, and our team of warehouse design engineers has been doing this for many years now. It has always been my premise that we do not just sell forklifts but offer complete warehouse solutions and this service, free of charge and with no obligation, has been invaluable for many customers around the globe. A more recent development is 3-D warehouse simulation so potential and current customers can see in real time what benefits we can offer when it comes to optimum use of space.

WLN – To what extent can you provide customised versions of your different trucks?

Our byword from the start has been customised handling solutions. Collaboration with the customer in the initial consultation process means that almost every Combilift that leaves the factory has been customised to meet individual requirements, whether this means a tailor-made mast, platform size, longer or shorter forks, smaller, larger or higher cabs and so on. As we sell around the world and therefore in very differing climates, we are also experienced in adapting our products to cope with the rigours of extreme heat or cold. Aisle-Master users on the whole seem to need a lesser degree of customisation since most pallets have the same dimensions but of course we offer this when required.

WLN – Focusing on the Aisle-Master range first of all, what different Aisle-Master models are available? Which are the biggest selling models? How has the Aisle-Master range developed since it became wholly part of Combilift?

There are a number of different chassis widths, ranging from the narrow chassis 15E model which was developed when we took over the Aisle-Master brand, to the standard SE model and the wider WHE Model, and load capacities from 1.5 to 2.5 tonnes are available. Lift heights now go up to an impressive 15m, and we offer AC electric and LPG power. We offer many options such as lift pre-height selector, fork camera and so on. We also introduced the fully enclosed cold store cab in 2102, which has increased productivity and driver comfort in what is an exacting working environment. The production of the electric powered Aisle-Master now far exceeds our LPG production.

WLN – Aisle-Master’s 85% sales increase year on year between 2010 and 2011 was pretty spectacular. How has growth been in recent months?

Aisle-Master sales growth continues at more than 50% and we are now producing 1 unit every 2 hours. The 85% figure was due to the introduction of new products and the fact that we were able to use our original network of Combilift dealers around the world to drive sales. Having a global presence enabled us to withstand slumps in some markets and capitalise on growth in others.

WLN – Combilift is also famous for its continual development of new models. What different models are available? Which Combilift models have been the biggest sellers, and in which applications?

If I were to list all the available models there would be no more space for any further questions! In a nutshell our range comprises the core C series with capacities from 2.5 to 25t, 4-way sideloaders, stand on models for operation in even narrower aisles, the XL large cab range with high ground clearance, the Combi-CB mentioned above, the rough terrain RT range and the Straddle Carrier (Combi-SC) for handling containers and over sized and heavy loads.

WLN – Which are your ‘biggest’ machines overall, in terms of lifting capacity?

The two giants of our range are the Combi-SC, which can lift and move loads of up to 50t from ground level and load them on and off HGV’s, and the C25000, which is the only four way forklift capable of handling 25t loads. The SC eliminates the need for cranes and has a much lower own weight and therefore ground pressure compared with any other piece of equipment capable of handling such capacities. It is a very cost effective solution for oversized products, and we have had exceptionally good sales of this since its launch. Although it was originally designed for container handling, 75% of sales are to other operations – handling steel and prefabricated modules for example.

WLN – What’s your smallest VNA machine?

The narrow chassis Aisle-Master 15E model is a 1.5t capacity truck with a chassis width of just 1030mm, ideal for operation with lighter loads which require extremely narrow operational aisles. If you want to see our new smallest VNA machine visit us at IMHX.

WLN – Do you lease and rent your trucks? Do you sell refurbished ex-hire trucks? Do you supply trucks in the UK direct or through distributor? Who are your current dealers in the UK?

Combilift continues to work through a wide network of dealerships which is too numerous to name individually. More and more dealers are choosing the Aisle-Master as their articulated truck of choice due to its reputation for extremely reliable operation, its build quality and low maintenance costs. We have recently put together a Combilift finance package with very attractive lease rates for our dealers and customers to avail themselves of.

WLN – Which are your main industry sectors in the UK for Aisle-Master and Combilift?

WLN – Which are your main industry sectors in the UK for Aisle-Master and Combilift?

Any company that wants to rationalise handling and storage, save space, improve productivity and save on multiple fleet costs is an ideal candidate for our products, and as such we have customers in almost any sector you can think of – from the more “mainstream” industries such as timber, plastics, steel and aluminium, food and drink, manufacturing and engineering, 3pl and so on, to more niche areas such as car salvage yards (Combilift) and vehicle dismantling centres (Aisle-Master.)

WLN – Seeing your products in action is key to understanding their benefits and wanting to use them in a business. Do you have videos available on the Internet and social media showing how your trucks work?

There is a wide selection of videos on our website and dozens more easily accessible on YouTube which give an instant insight into the versatility and manoeuvrability of our product range. We have not yet explored the benefit of using Social Media in our business.

WLN – I understand you are sponsoring a new FLTA Award for dealerships. Can you tell us more about that?

It is the new Customer Focus Award, which we initiated in appreciation of the invaluable contribution made by the industry’s dealerships. Their groundwork in the field with customers, analysis of specific requirements and problem solving that they offer is a crucial link in the chain when it comes to getting new solution products into the marketplace.

WLN – Talking of sponsoring awards, have either Aisle-Master or Combilift won any prizes?

2012 was quite a year for Combilift. We started off in style by winning the Innovation award for the Combi-RT at the FLTA awards in February as well as scooping the one off “winner of winners” trophy for the Combi-CB, which was a great honour. In November Combilift was named the Best Overall Exporter to Germany in the Irish Exporter to Germany Awards, organised by Enterprise Ireland and the German-Irish Chamber of Industry and Commerce.

WLN – In a highly competitive fork lift truck industry, what sets Combilift apart? Why buy a Combilift or Aisle-Master from you?

Over the years we have carved out a reputation for innovative products, and we offer a degree of customisation and a range of specialist solutions that is unmatched by any other manufacturer. We deliberately set out to make clever but simply engineered products, which are reliable, robust workhorses that are easy to maintain. Although we are more than happy to embrace new technology we do so only when it has a marked positive effect and not just for the sake of it. Repeat orders from major names across numerous industry sectors who operate large fleets of our products underline the quality and long life operation of our range.

WLN – I gather Combilift celebrated the delivery of its 10,000th truck in 2009. What’s the latest figure?

We have manufactured over 18,000 units now since production began – and the first ever Combilift that was sold to a builders’ provider in Monaghan is still going strong, by the way!

WLN – Your growth rate and success is pretty much unparalleled in this industry in recent years. What’s your secret?

The main aim has been consistent: we want continued growth, and we have achieved this by investing 8%-9% of our turnover annually in R&D and developing at least one new model each year since we established the company. Customer feedback has also played a major role in this, so when we launch a new model we know that we have customers out there waiting for it. We are not afraid to move in new directions when it comes to geographical as well as industry sector markets. Our strategy is to double our turnover in the coming five years. We’ll keep our other secrets to ourselves!

WLN – What new products and developments will you be showing at IMHX?

You will probably know by now that Combilift is very reticent about giving too much detail on new products in advance – you’ll have to wait until the show opens! All I will say is that we have recently focused on developing models at the smaller end of the scale following on from the recent accent on new larger machinery. We do plan to launch three new models at IMHX.

WLN – The big question: why should a busy professional from the logistics industry take a day out of the office to visit your stand?

Although you can watch videos and get all manner of information from websites and the Internet, I still believe that the personal interaction that you get at trade fairs is invaluable for forging business relationships. Our show stands incorporate a great mix of new products that people can experience close up, highly experienced sales and engineering professionals, as well as entertainment and Irish hospitality that cannot be replicated electronically, on the phone or in a meeting.

WLN – Finally, will you be celebrating Combilift’s fifteenth anniversary at some point in 2013?

WLN – Finally, will you be celebrating Combilift’s fifteenth anniversary at some point in 2013?

We will be marking 15 years in business at some of the major events we are attending this year around the world. Visitors to the hospitality area at IMHX will be able to take a look at displays illustrating the milestones in our (short!) history so far. Rather than just thinking of this year as an Anniversary, we like to think we have been lifting the material handling innovation bar for 15 years now.

Tel: + 353 (0)47 80500

email: info@combilift.com

Comments are closed.