The EDEKA Center Grünbauer in Weiden has been testing the automated supermarket shelf SRS (Shelf Replenishment System) provided by Witron Logistik + Informatik GmbH, Parkstein since mid-August. The SRS is a unique system designed to automatically replenish the sales front (shelf) within a retail store. At EDEKA, WITRON’s SRS is replenishing a 10 meter long section of shelf used to display an assortment of dry goods.

The EDEKA Center Grünbauer in Weiden has been testing the automated supermarket shelf SRS (Shelf Replenishment System) provided by Witron Logistik + Informatik GmbH, Parkstein since mid-August. The SRS is a unique system designed to automatically replenish the sales front (shelf) within a retail store. At EDEKA, WITRON’s SRS is replenishing a 10 meter long section of shelf used to display an assortment of dry goods.

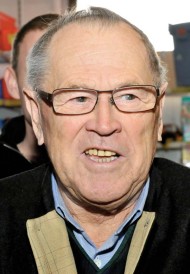

“Due to intensive cooperation with retail experts and rack suppliers, the test system developed in the WITRON Technology Center in Parkstein is now mature enough in view of design, functionality, and security for everyday practical use”, explains WITRON owner Walter Winkler. “With the integration of the SRS shelf into the supermarket, we will now be able to gain additional important knowledge for the next steps – with regards to functionality, consumer purchasing behavior, availability, and efficiency”, continues Winkler. “Moreover, we can incorporate the experiences gained in the supermarket directly into our logistics design for distribution centers”.

With the pilot installation in Weiden, both the operator of the E-Center, Klaus Grünbauer, and also the think tank around Walter Winkler, see a significant step in putting the system to the “acid test” in real operation. The EDEKA regional company (Nordbayern, Sachsen, Thüringen) responsible for the Weiden store showed great interest in the realization of this pilot project.

Interest in this technology was generated by studies that show 50% of retail supply chain costs occur at the store itself and there is still great improvement potential. Any increase in service level provides clear benefits to the consumer, and higher customer satisfaction leads to greater market share for the retailer.

“And this is where the patented SRS System of WITRON will really make a difference – a sustainable optimization of all logistics processes in the store”, is one of the reasons for the development of this innovation according to Walter Winkler.

With SRS, the retail store shelves are automatically replenished by shuttles. The shuttle quietly transports goods from the back room of the store into a replenishment aisle which is integrated inside the sales rack. The shuttle is loaded in a replenishment area of the supermarket, which is located outside the sales floor and cannot be seen by the customer. The SRS shelf and the replenishment area are connected through a network directly integrated in the roof above the sales floor. Thus it is possible that one shuttle supplies several shelves at the same time. The number of shuttles used depends on the size of the supermarket and the number of racks. In terms of IT, the SRS is connected to the ERP System of the supermarket. The SRS always knows the entire shelf inventory based on regular scanning, and it determines the optimum replenishment volume and replenishment time for each article. It is also possible to integrate electronic pricing with SRS, controlled through the ERP System via radio-frequency. Based on the technology used, all articles for sale are carefully carried and pushed during the replenishment process.

“With the SRS-supported replenishment of the store shelves, there are no more gaps in the shelves. All articles are permanently available and properly and clearly arranged in the front part of the sales shelf. Replenishment takes place directly into the sales front of the shelf – at the right time with the right quantity. This process is completely quiet, and it goes unnoticed by the customer while he or she makes their purchase. With system-controlled shelf replenishment, access to the store shelves is no longer blocked by employees filling up the shelves and aisles are no longer blocked by roll containers. Even on peak days with high customer frequency, shelves are always filled and all articles are easily accessible. Supermarket employees also benefit from SRS. Instead of having to replenish the shelves using un-ergonomic work procedures, they are now able to use their time for additional customer support. “Moreover, the time spent for inventory work is significantly reduced”, explains Walter Winkler one of the benefits compared to a conventional work procedure.

“With the SRS-supported replenishment of the store shelves, there are no more gaps in the shelves. All articles are permanently available and properly and clearly arranged in the front part of the sales shelf. Replenishment takes place directly into the sales front of the shelf – at the right time with the right quantity. This process is completely quiet, and it goes unnoticed by the customer while he or she makes their purchase. With system-controlled shelf replenishment, access to the store shelves is no longer blocked by employees filling up the shelves and aisles are no longer blocked by roll containers. Even on peak days with high customer frequency, shelves are always filled and all articles are easily accessible. Supermarket employees also benefit from SRS. Instead of having to replenish the shelves using un-ergonomic work procedures, they are now able to use their time for additional customer support. “Moreover, the time spent for inventory work is significantly reduced”, explains Walter Winkler one of the benefits compared to a conventional work procedure.

Klaus Grünbauer, director of the Weiden store, and Walter Winkler look with optimism towards the future. According to Mr. Gruenbauer, “the SRS shelf was immediately accepted by the consumer. Based on the pilot system, benefits for the customer and our business are clearly visible. State-of-the-art technology makes shopping at our store an experience. I look forward to actively supporting the further development of the solution”, the positive feedback from Klaus Grünbauer. According to Walter Winkler, WITRON is also looking forward with great excitement at the potential of SRS. “We are currently concentrating on this pilot installation, and we are focused on exploring opportunities to optimize the design even further based on lessons learned in real operation.

WITRON Logistik + Informatik GmbH

Frau Cornelia Troglauer, Marketing

Tel. +49/(0)9602/600-227

Email: marketing@witron.de

Comments are closed.