As on-the spot vehicle enforcement weight checks rise and awareness of the risk of axle overloading increases, remaining within weight restrictions is an increasingly sensitive area for all fleet managers and operators. With this in mind, RDS Technology will be exhibiting the Axlog Alpha overload warning indicator at the Food and Drink Logistics Show 2010.

As on-the spot vehicle enforcement weight checks rise and awareness of the risk of axle overloading increases, remaining within weight restrictions is an increasingly sensitive area for all fleet managers and operators. With this in mind, RDS Technology will be exhibiting the Axlog Alpha overload warning indicator at the Food and Drink Logistics Show 2010.

Suitable for all vehicles with conventional steel suspension or vehicles with air suspension i.e RCVs, the Axlog Alpha system displays the individual gross axle load and gross vehicle weight, helping operators avoid overloads and the heavy fines and points that can come with being prosecuted.

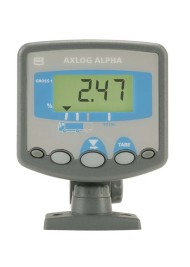

Already a success across many local councils and fleet contractors, the Axlog Alpha is a simple to use and cost-effective means of increasing vehicle safety on the roads and decreasing wear and tear and fuel costs. Weight limits are programmed during installation. The head unit, mounted in the driver’s cab, has an illuminated 4-digit LCD display, 2 active front panel switches for all functions and an internal audible alarm. An external alarm is optional.

Also on show will be the Liftalert, Liftlog 100 and the new Liftlog 100+. These systems offer load monitoring and weighing functions with an internal alarm to warn when load threshold is approached and at the overload point. The Liftlog 100+ offers a totalising feature, making it ideal for applications where multiple pallets are to be check-weighed or loading storage systems where weight limits are to be adhered to.

Negating the need to travel to a floor-mounted platform scale often sited in a remote part of the warehouse, the Liftlog range provides a time efficient means of check weighing.

Negating the need to travel to a floor-mounted platform scale often sited in a remote part of the warehouse, the Liftlog range provides a time efficient means of check weighing.

RDS Business Development Manager, Mark Evans, said, “The current relevance of our weighing and overload warning systems for forklifts and road vehicles will ensure a visit to our stand at the Food and Drinks Logistics Show is particularly beneficial.”

For more information on how on-board weighing and data handling be used to help improve your operations, visit RDS on stand Y004 or visit: www.rdstec.com.

Comments are closed.