Dematic presents the Dematic PackMyRide automation system, the world’s first fully automated solution concept for parcel loading. Currently, the Subsystem is being tested in a pilot project at one of the newest distribution centres of project partner DPD in Nagold. There, the system picks up packages from an existing intralogistics system and moves them to mobile racks via a rack feeder device. The racks are designed in a way that allows Dematic’s Automated Guided Vehicles (AGVs) to fully automatically transport them into the delivery vehicle. This will not only reduce the physical work of the delivery drivers, but will also add value by significantly reducing the time required for loading vehicles. It is expected that up to 80 percent of the package range can be handled by the system.

“With Dematic PackMyRide, we’re revolutionising parcel loading for the last mile by introducing the world’s first automated solution concept in this segment,” says Dr. Daniel Jarr, Project Lead for Dematic PackMyRide. With the automation system, several delivery tours can be loaded simultaneously, offering significantly higher productivity and efficiency in parcel handling. “Our innovative solution concept not only provides ergonomic relief for drivers, but also saves a great deal of time, which benefits the delivery company along the value chain,” says Jarr.

Thomas Steverding, Senior Group Manager for Process & Development at DPD Germany, explains why the parcel service provider readily participated in this project: “While our parcel sorter systems are already highly automated, at the end of the process the packages for the last mile are still handled completely manually. For the first time, Dematic’s innovative concept shows how we can support and relieve the human workforce at this point. We are very pleased to test this promising development.”

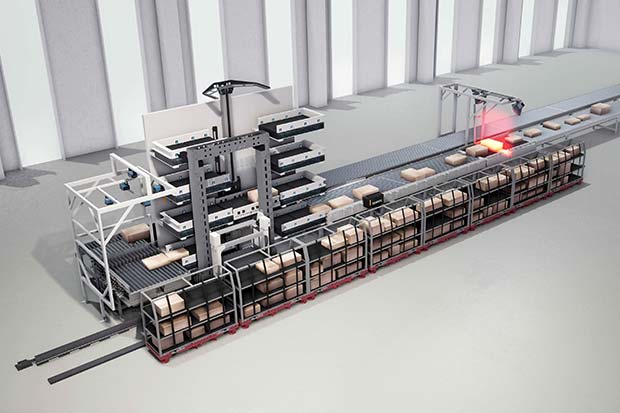

The system is currently being tested in a distribution centre of development partner DPD. Dematic PackMyRide receives the packages from the intralogistics system and transports them to a scanning unit, where volume, weight and barcode data are verified for optimal sorting. In the Dematic Sequencing Tower, the packages are then stored temporarily to pass them in the desired order to a pusher unit. At this point, the system differentiates between two types of packages. Jarr explains: “If something is wrong with the package, it will be redirected to a manual line.” Otherwise, the package is loaded onto a rack feeder that moves along lined up mobile racks and places the packages at the pre-calculated location. When a rack is fully loaded, it can easily be removed from the system and transported to the delivery vehicle manually. As an alternative, Dematic provides automatic transport with its AGV-Systems.

DEMATIC

Comments are closed.