The first question this month looks at what previous experience and qualifications are needed to become a SEMA Approved Rack Inspector. Our second question looks at the safety aspect of removing parts of racking to facilitate the storage of larger items and how this may affect performance.

SARI, what’s involved?

Q We are looking at the long term benefits of having one of our employees becoming a SEMA approved racking inspector. What pre qualifications are required to do the training and what is the definition of storage equipment and does office storage racking need to be inspected by a SARI inspector?

A. As far as pre qualifications are concerned there are two things we look for:

1) The candidate should be able to demonstrate that they can write a technical report in good English so that a non-technical client would be able to understand what was being said and to comprehend the reasoning behind what was being recommended.

2) The candidate should ideally have some experience of racking and racking inspections. While the course covers the required area, the skills of observation are not something that can be taught in a classroom and we know from experience that people who have not done such work before coming on the course will inevitably struggle.

To some the cost of the course will represent a significant investment and accomplishment is dependent on candidates passing both a written examination and a practical assessment, so success is not guaranteed. We try to ensure that those accepted on the course realise that this is not an easy qualification to obtain and that it does require some considerable effort and knowledge that will have been gained through experience.

As far as shelving is concerned this is the grey area between racking which definitely does need inspection and office furniture which doesn’t, although we have seen some serious incidents with “office furniture” which may have been prevented by a regular inspection. This boils down to a risk assessment of the individual work place on a case by case basis.

There is no legal requirement that a SARI inspector should be used for any inspection. The requirement is that an inspection should be done by a ‘competent person’ and the SARI scheme is recognised as one of the better ways of demonstrating that a person has that level of competence.

Removing parts

Removing parts

Q Following an installation by a client, which included bolting the racking to the floor, the users of the racking have removed the bottom rail. Can you please advise if this would be an acceptable practice or would removal of this rail compromise the structural integrity of the racking.

A. We presume that you are talking about the bottom-most beam level (which looks to be about 150mm above the floor).

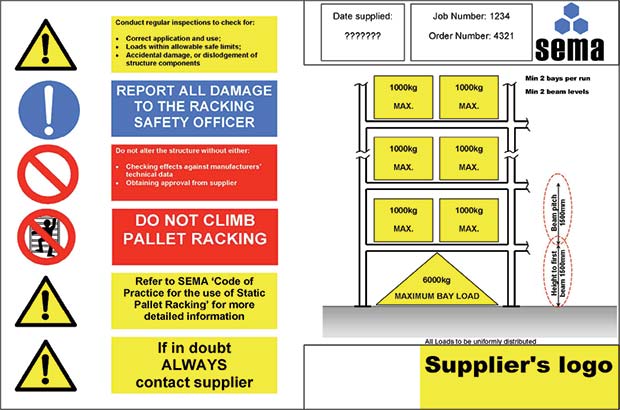

The racking should have a load notice on it somewhere which should look something similar to the one shown.

This arrangement of load sign is given in the SEMA code of practice for load signs http://www.sema.org.uk/codes of practice and is similar to that recommended in EN15635 and as given in figure 48 of the HSE publication HSG76 http://www.hse.gov.uk/warehousing & storage. This is an example and there are some items on it that should answer your question.

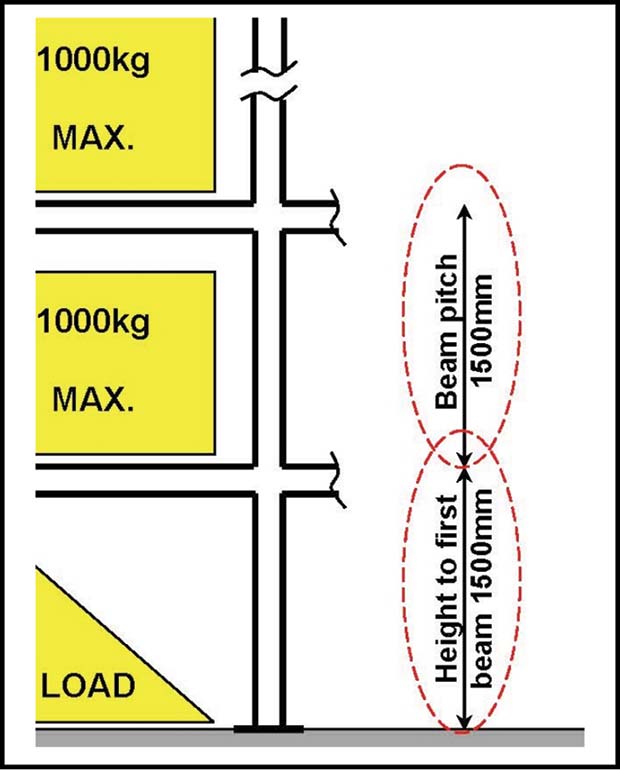

I have highlighted (with red dashed ovals) the height to the first beam level and the dimension from the first to second beam level.

This data is a key part of the rack design and the information shown here should match the actual configuration on site. If the actual dimensions are greater than those given on the load sign then the rack may be under-designed and unsafe, similarly if beams have been removed (thereby increasing the design dimensions) then the rack may be under-designed and unsafe. In such circumstances your client should refer to the equipment supplier, as recommended in the box on the bottom right corner of the sign, to have the design of the modified configuration checked.

If the racking does not have a load sign fitted then your client should contact the equipment supplier to get one fitted as soon as possible. The load sign is a key piece of safety equipment and is one of the things that an EHO or HSE inspector will check should they visit site.

SEMA is delighted to be working with WLN on the storage Q and A Column. On the WLN website is a list of previously published columns which we hope you find useful.

Comments are closed.