Two questions again this month, the first looks at the need to fit pallet stop bars or grid panelling between an existing standard double run of racking. Our second question involves the legality of using only one bolt to secure the front racking leg.

Two questions again this month, the first looks at the need to fit pallet stop bars or grid panelling between an existing standard double run of racking. Our second question involves the legality of using only one bolt to secure the front racking leg.

Fitting pallet stop bars or grid panelling

Q. We currently use reach trucks in a pallet / picking warehouse. The height of the racking is 6000 mm. and the aisle width is 3000 mm. We pick from low level at all locations.

Following an inspection we have been informed that we need to fit pallet stops on the back of each row of racking, or grid panelling between each double row of racking. The reason given for this statement is that it will reduce the threat of product being pushed from one row of the racking onto the other row, thus causing product to fall into the aisle.

We have some doubts about conforming with this request as we believe it may lead to operators using the stops as a brake and causing problems with the loads inflicted on the structure. Can you please advise?

A. We know of no requirement in any Code of Practice in this country or elsewhere to fit grid panelling between rows of racking in a pallet / order picking environment. This is sometimes done if there is a particular possibility of goods falling off high level pallets and injuring order pickers or other that might be working unprotected at lower levels. We would have expected your risk assessment for the operation to have considered this and come to a conclusion on the matter. Unstable pallet loads are not suitable for storage on racking in any event.

With regard to the use of pallet stops, SEMA codes of practice specifically recommend against the use of pallet back stops of any sort on the grounds that they encourage incorrect operation of aisle equipment.

The published FEM (European) Code, while not so adamant on the use of stops, does raise the issue that if they are fitted then it will be necessary to stipulate the likely forces to be absorbed by the structure as a result of the truck operators using them in place of a brake. The racking must then be designed to accommodate these extra forces, which will be of a significant magnitude. It is unlikely that stops could be fitted to an existing installation, as the existing racking would be unable to absorb these extra forces.

If the spacing between the back to back racking has been correctly specified there should be sufficient space in the flue between the racks that it should not be possible to incorrectly place a pallet in one aisle and dislodge a pallet in the adjacent aisle. Normally even if the front face of the pallet is level with the front face of the beam, which a good operator would not do, this should still not dislodge a pallet in the adjacent aisle.

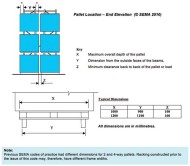

We would refer you to the SEMA Code of Practice – Use of Static Pallet Racking, which sets out the recommendations on clearances for different sizes and types of pallets in this type of installation. (see diagram)

Only one bolt, is this Safe?

Q. I have just taken charge of a warehouse and have noticed there is only one bolt in the front racking leg, the racking leg supports 8000kg at an height of 9 meters. Is this correct or will I need to place a second bolt in the upright lag.

A. Unfortunately we would need rather more information than you have provided in order to make a definite statement and can only offer the following generalities for the moment.

Some manufacturers of racking including major brands such as Link 51 and Dexion will design racking with both single and double bolted base plates depending upon the required loading capacity of the upright. (Double bolted will usually carry slightly more load than single bolted). Other manufacturers HiLo for example will always double bolt so the strict answer to your query is that ‘it all depends.’

If you can tell us who manufactured the racking it is possible that we can give you more advice but presumably if you knew this you would have approached that supplier direct’ If you do not know the manufacturer but can send us a digital photograph of the rack concerned we are happy to look at it and give you what advice we can.

SEMA is delighted to be working with WLN on the storage Question and Answer Column. On the WLN website is a list of previously published columns.

SEMA is delighted to be working with WLN on the storage Question and Answer Column. On the WLN website is a list of previously published columns.

Please note that SEMA Users Club members also have access to a comprehensive range of additional storage related questions and answers.

SEMA Technical Enquiries

If you have a query send it to us and we will do our best to have it answered by one of our technical experts.

SEMA Rack Safety Awareness and Inspection Courses

SEMA runs a one-day safety course on Rack Safety Awareness and Inspection. These courses are aimed at end users, giving an in-depth look at the need for inspections, how to conduct an assessment and what actions to take when this is completed.

SEMA Approved Rack Inspectors Qualification

This qualification is aimed at professionals who conduct rack surveys as an integral and significant part of their duties. It involves delegates in undertaking an in-depth SEMA Course, together with an examination and practical assessment. CPD will be an important part of the qualification, demonstrating to end users that SEMA Approved Inspectors maintain a high professional standard.

SEMA Publications

SEMA publishes a number of documents – all of which are available from our Office. For further information visit, www.sema.org.uk. and click ‘Codes of Practice’.

SEMA USERS Club

SEMA runs a USERS Club designed to be of benefit to purchasers and users of storage equipment. Members receive newsletters, access to specialised events and discounted rates on publications and codes of practice.

For more information, go to www.sema.org.uk

Comments are closed.