Racking of differing heights and how this should be treated forms the basis of our first question this month. Then we look at the correct way to restore a warehouse floor after storage racking has been removed.

The Highs and Lows of Racking

Q. One of our warehouses has just had their racking moved. However, on some aisles the heights of the bays are lower than others. This is causing problems with the new fleet of FLT trucks and we have been experiencing racking damage. How can we check the carrying capacity of the rack and where do we get that information from?

A. You say the height of the bays has changed on some aisles. We are not entirely sure what you mean by this but assume that you mean that the height of some beams (the horizontal members upon which you place the pallets) has changed and is now unacceptable for your new trucks. You plan to move these beams (presumably raising them) so that your new trucks do not hit the rack.

All racking should have a load notice in order that it can be used safely and the following is a link to the SEMA web-site – www.sema.org.uk/guides.asp

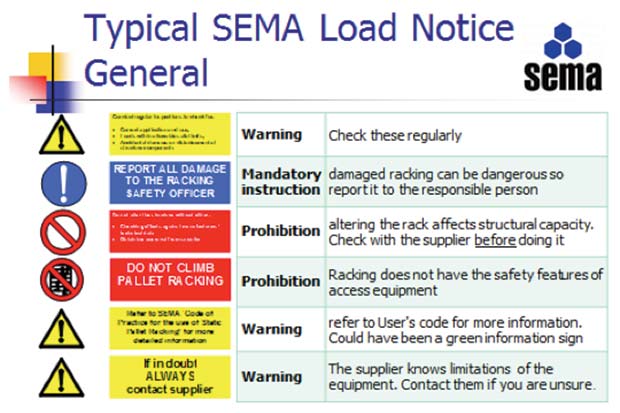

Below we have extracted some of the information that you should have on your SEMA load notices. This gives the general warnings and safety information relevant to racking.

The drawings below show these general warnings along with a short explanation of their purpose. One of the warnings given on the load notice relates to alterations to the structure.

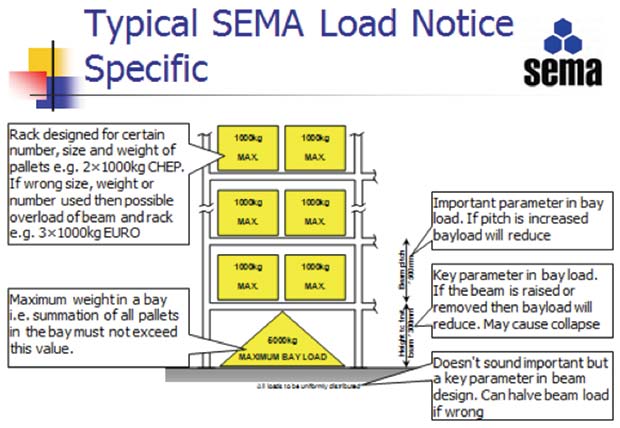

Elsewhere on the load notice you should see something similar to the following (again the text in the boxes is an explanation of what the information means)

The height between levels and height to first level should be given. The rack should comply with these dimensions.

If the information given on the load notice and the actual situation are different then the load notice is no longer valid new load notices should be obtained based on the actual situation. This should normally be obtained from the OEM.

The safe working load (SWL) of pallet racking depends upon many factors such as the configuration of the rack, the “duty” of the members, quality of installation, etc. etc. and is normally derived by the racking manufacturer using codes of practice and structural engineering theory augmented by testing. SEMA does not hold load data for the various suppliers of racking and you should approach the equipment supplier for this data. Contact information is available on the SEMA website www.sema.org.uk/about_mem.asp.

It may be found that some OEM’s will refuse to provide you with load data as they will not take responsibility for a product which; might not be their manufacture, may not have been refurbished in accordance with their quality requirements, may have been re-worked using incompatible components, may not have been installed correctly etc. etc. Some OEM’s may insist upon carrying out a survey before they will provide new load data (such a service would normally be chargeable).

If the OEM cannot supply load data there are a number of Consultants who may be able to provide you with load data and/or supply safe load data signs. (www.sema.org.uk/page.asp?) although, once again, they may be unwilling to provide data for a product where the provenance is unclear. Such a service would normally be chargeable.

Restoring the floor

Q. We are vacating a warehouse we have rented for three years and are removing the racking. The owner of the premises has said we need to get the bolts out of the ground and make good the floor or he will have to get someone to do the work and back charge us. We have contacted a few racking companies who we deal with and they say they use an angle grinder to level the surface, so nothing is left proud and the floor is left smooth. We plan to do this and then screed over and touch up with paint, would SEMA consider this to be the correct course of action?

A. We are not aware of any guidance on this subject. The general subject of remediation is normally covered in the tenancy agreement between your company and the building owner and you should refer to this document.

It is sometimes possible to remove mechanical type floor anchors although this is rather time consuming. If they have been installed by an experienced team it is possible that the holes into the floor will have been drilled deeper than necessary at installation to allow the fixings to be tapped fully into the floor when no longer required. Unfortunately this does not always happen. Removing chemical anchors (or mechanical anchors that have been glued into place) is very difficult without doing severe damage to the floor. The normal approach is to grind off or saw off with a reciprocating saw the protruding anchors possibly followed by resealing the hole with a two pack epoxy resin and/or painting the floor.

Whilst it may not help you just now there are some anchors which have a bolt (instead of a stud) that screws in to a fitment in the slab (similar in principle to the plastic wall plug used in domestic DIY); with this type the bolt can be removed (leaving the fitment embedded in the slab) so that the only remediation necessary is to grout up the hole. Similarly there are types of floor fixing similar to a ‘coach bolt’ where a hardened thread on the bolt screws in the side wall of the hole in the concrete. This fixing can be removed in totality however the hole then needs filling with epoxy resin or similar material.

A date for your diary

The 2015 SEMA Safety Conference is on Thursday, 5 November; at the National Motorcycle Museum, Solihull. For full details contact SEMA at enquiry@sema.org.uk

SEMA Rack Safety Awareness and Inspection Courses

SEMA runs a one-day safety course on Rack Safety Awareness and Inspection. These courses are aimed at end users, giving an in-depth look at the need for inspections, how to conduct an assessment and what actions to take when this is completed.

SEMA Approved Rack Inspectors Qualification

Aimed at professionals who conduct rack surveys as an integral and significant part of their duties. It involves delegates in undertaking an in-depth SEMA Course, together with an examination and practical assessment.

SEMA Publications

SEMA has 26 publications in stock – Codes of Practice, ‘Guides’ and European documents – all available from our Offices.

SEMA USERS Club

Designed to be of benefit to purchasers and users of storage equipment. Members receive newsletters, access to specialised events and discounted rates on publications and codes of practice.

Comments are closed.