Loadhog products are designed and manufactured to eliminate single use packaging, helping supply chains save time, money and waste, while increasing efficiency and sustainability. They do this in 3 steps; eliminating unnecessary waste, circulating to avoid waste and designing waste into innovative packaging solutions.

Eliminating unnecessary waste:

Eliminating unnecessary waste:

If we don’t start to rethink plastic, there will be more plastic in the ocean than fish (by weight) by 2050. Recycling plastics and reusing materials within packaging helps to eliminate the unnecessary waste generated by supply chains, as roughly 40% of all plastic produced is single use plastic packaging.

Loadhog are brightening up your supply chain with recycled plastics. As a sustainably minded company, Loadhog, has made the decision to ensure that recycled material is used across its product range.

A large proportion of Loadhog’s products already include at least 30% recycled material, and with them now removing 100% standard virgin products wherever possible, the company is pushing towards a more sustainable future.

Loadhog, returnable packaging expert, has released its brand new recycled material colour range, offering a wide range of bright colours, as well as the standard black and grey.

The new repro material has been tried and tested against 100% virgin containers and has proven to be stronger and more durable.

The advantages of increased sustainability and lowered carbon emissions are what create an impact on companies’ environmental targets. Increasing the adoption of recycled material used within the industry creates sustainable packaging solutions that more and more businesses are looking for.

Circulating to avoid waste:

Plastic brings many benefits. It’s strong, durable and secure. All traits that work well within packaging.

However, there are some challenging single use plastic items that need to be eliminated to achieve the desired circular economy.

With companies now putting sustainability at the forefront of their business models, the circular economy is becoming the norm. Reusable containers have 88% less CO2 emissions than single use cardboard boxes, and this isn’t the only benefit Loadhog’s returnable packaging can bring to businesses and their supply chains.

By designing out waste and keeping materials in use, Loadhog solutions regenerate rather than degrade natural systems, powerfully contributing towards the environment.

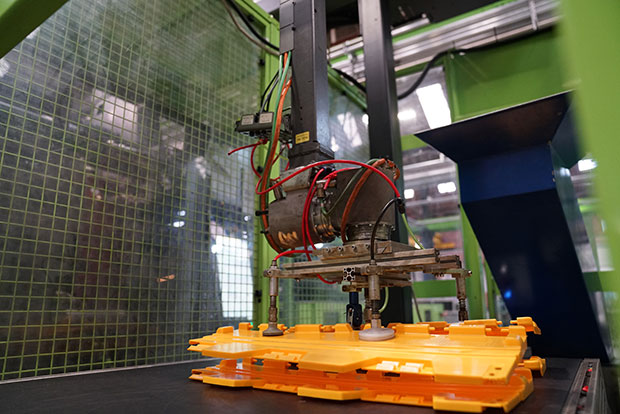

Loadhog designs its products to be used and reused right from the initial idea, with a ‘no waste’ outcome in mind. The reusable packaging solutions are manufactured using recycled materials from the start when injection moulded to reusing plastics at the end of a product’s life span.

By using Loadhog packaging, and moving your supply chain from linear to circular, it creates opportunities from the outset, including improved efficiency, cost saving, and increased sustainability.

Designing waste into innovative packaging solutions:

Loadhog designs and innovates its products to ensure that the plastics they use are reusable, recyclable and repairable. Their expert design team has years of experience in innovation; from designing returnable packaging solutions for supply chains, to creating new innovative products to meet specific customer and market needs.

As well as the existing product line, Loadhog can design and manufacture products to meet specific needs of the customer. For example, if the customer is already using returnable packaging but has problems with breakages or usability, Loadhog’s design team will adapt, change and implement solutions to meet the customers’ requirements, while solving their problems.

Loadhog were already designing and manufacturing Attached Lid Containers when a popular UK clothing retailer approached them with problems with their existing containers. They challenged Loadhog to fix the problems they were having and worked in conjunction with the design team to find the following solutions:

-Adding a ribbed base for stiffness and noise reduction

-Using alternative material to avoid breakages on impact

-Adding the lid tessellation of a Helios

-Innovating the hinge pin security to prevent pull through

-Stepped wall design that mirrors and works with existing containers

The retailer also challenged an automation feature, which Loadhog proposed the specific collar design. From this came the Artemis, an addition to the ALC range. The Artemis enabled the retailer to be more efficient, reduce waste and increase security.

Loadhog brings extra value by learning, understanding and developing a product that will increase efficiency and usability within a customer’s supply chain.

Loadhog Ltd

t: 0114 2800 800

Comments are closed.