Established by Fritz Schaefer in Germany in 1937, SSI Schaefer is a fully family-owned business, Headquartered in Neunkirchen, Germany, with a global reach including more than 55 subsidiaries worldwide and some 9,000 employees.

Business Development & Marketing Manager

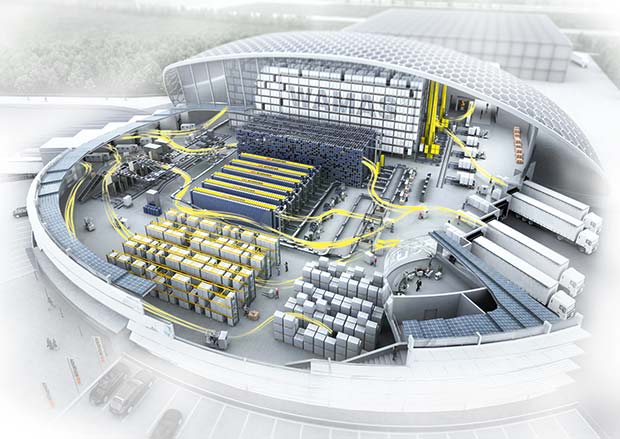

The early years of the business revolved around the manufacture of steel products and the company is now a major global player in technology and an award-winning provider of automated materials handling equipment and integrated storage solutions, with products ranging from plastic totes to high bay pallet warehouses and warehouse management software.

The organisation offers expertise in the design, build, installation and maintenance of major, and often bespoke, production and distribution centre operations across a broad spectrum of commercial and industrial sectors.

Mike Alibone, Business Development & Marketing Manager at SSI Schaefer, spoke to Warehouse & Logistics News.

WLN – What are your best-known products and services?

SSI Schaefer has a long history in the supply of storage equipment. For more than 75 years we have been actively involved in developing systems which enable us to provide our customers with solutions specifically tailored to the storage of both unique and generic products. Our core products are based on simple pallet racking and shelving storage systems and metal and plastic containers. Over the past 17 years we have also been supplying solutions which automate the storage and retrieval of products within these systems – specifically conveyors, pallet and miniload cranes, shuttles, automatic picking, and AGVs. We have also extended our product portfolio to include warehouse management and control software and integration of other system-related products. Robotics is now playing an increasingly important role in our solutions provision.

WLN –Which market sectors and countries are your customers in? Which ones are growing fastest?

We operate across a wide variety of market sectors, ranging from frozen food and pharma distribution to hanging garment retail and the automotive aftermarket. Our solutions are implemented in manufacturing & production facilities and distribution centres in developed countries across the globe. With growth of online ordering, retail/e-retail is probably represents the fastest growth area.

![]() WLN –Who are your major customers and what do you do for them?

WLN –Who are your major customers and what do you do for them?

Warehouse systems for Sainsburys, Wiggle and Oxford’s Bodleian Library are some examples of recent major customer projects. These projects all involve the installation of pallet racking and shelving, some of which is serviced by automated pallet cranes. There are also elements of carton live storage, conveyors and controls with integrated peripheral equipment such as printers and label applicators.

WLN – How do your products benefit your customers’ businesses?

Our solutions are designed to make the most effective use of available space, while at the same time lowering operating costs through the reduction of labour and the introduction of power-saving systems.

WLN – Why should customers choose you as their main supplier in your area?

We are financially independent and committed to long-term solutions for our customers. We are unique insomuch as we provide single source solutions from our own production, which guarantees perfectly-matched, high quality components that are up to date with the latest technological standards. As general contractor we project manage system installations to the highest standards of safety and quality.

WLN – What’s business been like in the past year? How have conditions changed over this period and how have you reacted?

Business has remained buoyant, with substantial new and ongoing project work continuing to fuel our growth plans. At a global level, the company has made several acquisitions to increase and enhance our product and solutions capability.

WLN – What were the business highlights for you in the last 12 months?

Always difficult to answer specifically, as in most instances our big contract customers do not like to broadcast too much about systems from us which give them a competitive advantage. Suffice to say that news of our most cutting edge solutions adopted by some of the larger retail organisations will emerge in due course.

WLN – How have you fine-tuned your offering in the last 12 months and why?

As well as investing in more efficient manufacturing processes we have made enhancements to our IT systems, extended our Customer Services and introduced some new pieces to our sales toolkit.

WLN –What recent enhancements have you made in customer service?

Our customer service team continues to grow, providing greater coverage and even better response times for our customers. We have also introduced SSI Augmented Support – the first multi-functional, mobile, real-time video communication system that provides everything necessary for efficient maintenance and repair work. The system is highly flexible and user-friendly, and as a consequence it improves the working processes in many areas while also saving on time and costs.

WLN – What new products have you brought out?

WLN – What new products have you brought out?

Following the recent development of our autoguided transport systems these have become a popular choice for operations requiring flexible transport within the warehouse, distribution centre or production site – environments in which traditional conveyor systems may not be suitable. The AGV fleet from SSI Schaefer features a diverse range of solutions for large and small load carriers that are capable of creating a logistics network to connect disparate areas. These trackless AGVs have sophisticated built-in sensors which detect human presence in the vicinity of their operating areas and will momentarily shut down to avoid potentially fatal collisions.

WLN – What factors do you see affecting your business in the coming year? How will you turn these into opportunities?

The forthcoming year is likely to be laced with uncertainty as far as our potential clients are concerned. At the risk of using ‘the B word’, we continue to experience mixed reactions to the Brexit decision of 2016, with some customers holding off decisions on new facilities and systems until a clearer trading picture emerges. Others appear to remain unconcerned and continue to plan for growth. The anticipated post-Brexit labour shortage may well force companies to consider, or reconsider, the benefits of automation. We are ready to help and advise.

WLN – Are you planning to branch into any new areas, target new customers and take on more people?

Our customer base is as diverse as our product portfolio, which enables us already to offer solutions to almost all areas of industry. As an organisation in the UK we are continually growing – particularly as we complete more installations which become reliant upon our providing an ongoing support and maintenance service.

WLN – Are you investing in new premises and extra staff? What about staff development and training?

To accommodate our continuing business growth, in September 2017 we moved our Midlands-based operation into a brand new building, a much larger premises on the business park which has witnessed four similar upward moves over the last 16 years. In addition to external training, all SSI Schaefer employees undertake our own, intensive company training course which covers a broad scope of topics, ranging from product knowledge through business protocol to health and safety.

WLN – Are you involved in any major trade shows or other industry events over the next year?

Yes, as early as February we will be exhibiting at Southern Manufacturing & Electronics at Farnborough as well as hosting our own and attending and speaking at several supply chain events.

WLN –What big news from SSI Schaefer can our readers look forward to seeing in Warehouse & Logistics News in 2018?

Nothing we can reveal at this point in time, so watch this space!

WLN – And finally, if you had to sum up your company in a tweet what would it be?

SSI Schaefer is the most powerful solutions provider of materials handling products and systems worldwide.

SSI SCHAEFER LTD

01264 386600

Comments are closed.