Two questions this month on the correct use and storage of pallets, the first looks at spacing and the use of back stops and the second asks about restrictions when using Euro pallets on 1200mm wide racking.

Should Back stops be used as a safety precaution

Q. I am working with a company who have recently had their racking replaced to provide a 200mm clearance between the backs of the racking but there are concerns about the possibility of pallets being pushed off the racking behind. The company have suggested relying on training operators to put pallets away correctly to avoid this occurrence i.e. having a 30mm overhang at the front.

I believe this relies too heavily on the operator to get it right every time. Should the Company install backstops or wire mesh to prevent contact between the backs of pallets?

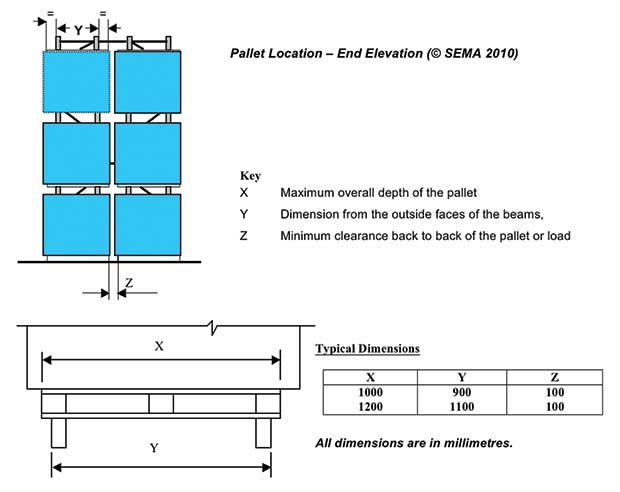

A. It is correct that the pallet overhang at the front and rear beams should be equal with the recommended clearance between the back to back pallets being 100mm with 50mm overhang at both front and rear. This should be sufficient to avoid rear impacts.

It is difficult to comment on a specific site without a detailed knowledge of the operation and racking configuration. The SEMA Code for the Use of Static Pallet Racking (free download from the SEMA web site) confirms that SEMA do not recommend the use of these components however it gives guidance on what it is necessary to consider if they are being considered.

The published FEM (European) Code, while not so resolute on recommending against the use of back stops, does raise the question that if they are fitted then it would be necessary to stipulate the likely forces to be absorbed by the structure including the possibility of truck operators using them in place of a brake. The racking should then be designed to accommodate these extra forces, which could be of a significant magnitude. It is unlikely that stops could be retro fitted to an installation, as the existing racking would be unable to absorb these extra forces and possibly the clearance between the back to back racks would not be sufficient to allow them to be inserted.

If the spacing between the back to back racking has been correctly specified there should be sufficient space in the flue between the racks that it should not be possible to incorrectly place a pallet in one aisle and dislodge a pallet in the adjacent aisle.

Even if the front face of the pallet is level with the front face of the beam, which a good operator would not do, this should still not dislodge a pallet in the next aisle.

Use of Euro pallets on 1200 mm wide racking

Q. Could you please advise us if there are any restrictions and / or legal implications to putting Euro pallets onto 1200mm wide racking?

A. Assuming you are using standard 800mm x 1200mm euro pallets located with the 800 mm face to the aisle then placing them in this orientation should present no problem as the bottom boards of the pallet span between the support beams and 3 pallets per 2700mm pallet support beam is quite a common application. If the pallets are located such that the 1200 mm face is to the aisle then there is no bottom board spanning between the support beams and this is a problem.

The SEMA recommendations are that for a pallet supported in the 1200mm direction the pallet racking end frame should be 1100mm. This will allow a 50mm overhang of the pallet at front and back support beams which permits a reasonable amount of operator error in pallet placement, which will inevitably occur. If you are using 1200mm frames to support 1200mm pallets then the operators will have to place the pallets flush with the front face of the rack to ensure that the pallet is located on the back beam. Pallets themselves have a manufacturing tolerance – so you could have a situation where an operator places a pallet that is say 12mm undersize such that it overhangs the front beam by 15mm due to placement inaccuracy. In such circumstances you could find the rear of the pallet only supported by 12mm on the rear beam which is not a lot if accidental impacts and movement are then considered.

If this is the case you would appear to have two options. The first would be to have the frame depth changed which would involve stripping down the racking and substituting replacement frame bracing to give you a 1100mm frame as recommended. The second option would be to provide two pallet support bars per pallet spanning between front and back beams located under the bottom boards of each pallet. This would in effect prevent the pallet from falling off the rear beam and would have the advantage that stripping down the racking would not be necessary. Most racking suppliers will provide pallet support beams as part of their standard range to allow varying sized pallets to be accommodated.

Comments are closed.