Warehouse & Logistics News is proud to bring you the thirty-seventh instalment in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world.

Warehouse & Logistics News is proud to bring you the thirty-seventh instalment in our exclusive series on the history of the fork lift truck, the machine that over the decades has revolutionised the face of materials handling around the world.

Our writer is James Brindley, an acknowledged authority on fork lift trucks. James’s distinguished career has involved engineering and management roles with BT Rolatruc and serving as a Director of the Fork Lift Truck Association, before he set up the National Fork Truck Heritage Centre in 2004 as Britain’s first such collection open to the public.

The Heritage Centre continues to need your support in 2009, and if you or your company would like to help in any way, you can contact James on the number below. Now sit back and enjoy the latest part of this fascinating series.

Episode 37: 1961: Soviets in space, Hyster in reach truck breakthrough

More news from 1961 included Britain making its first formal application to join the E.E.C., and once again the Russians having space all to themselves in the form of Major Yuri Gargarin orbiting the earth as the crew of the first manned spaceship.

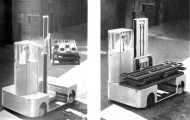

Back on earth again, Hyster-Ransomes launched the R.25.A compact reach truck at a price of £1,750 including battery and charger. The manufacturer, in their sales literature, made the most of the scissor action reach mechanism, which eliminated the use of chains (a reference here perhaps to the Lansing Bagnall reach models.) The feature was a double acting hydraulic ram, which operated a pantograph in a 27-inch advance and retraction movement. The benefit to the customer was explained as a high efficiency transfer of motion drawing a minimum amount of current from the battery and giving protection from misalignment of the mast assembly in the mainframe. The control frame, which also housed the drive motor and stabiliser wheel, was centrally pivoted with the mainframe. Any movement was damped out by a rubber bush at either side of the truck, ensuring four-wheel contact with the ground was maintained.

Back on earth again, Hyster-Ransomes launched the R.25.A compact reach truck at a price of £1,750 including battery and charger. The manufacturer, in their sales literature, made the most of the scissor action reach mechanism, which eliminated the use of chains (a reference here perhaps to the Lansing Bagnall reach models.) The feature was a double acting hydraulic ram, which operated a pantograph in a 27-inch advance and retraction movement. The benefit to the customer was explained as a high efficiency transfer of motion drawing a minimum amount of current from the battery and giving protection from misalignment of the mast assembly in the mainframe. The control frame, which also housed the drive motor and stabiliser wheel, was centrally pivoted with the mainframe. Any movement was damped out by a rubber bush at either side of the truck, ensuring four-wheel contact with the ground was maintained.

During July, fork lift truck handling was introduced into the Coventry City Fire Brigade’s training schedule. Training, supplied by Coventry Climax Engines Ltd at one of their factories, would teach the firemen all aspects of forklift driving and operation. Coventry City Fire Chiefs said that many of the fires that broke out in factories could be limited in their spread, if combustible materials in the area of outbreak were quickly removed. It was found that often fork lift trucks had been available but since fires are invariably discovered outside working hours the operators had not been there, with the result that the trucks have stood idle at times of urgent need. With this tuition the Chiefs were confident that the trained men would be able to move bulk material away from the danger source when no regular operator was available.

The latest product to be released by Cleco Electric Industries was the dual side loading forklift truck. It was designed to accommodate the normal functions of reach truck and counterbalance with all the benefits of a side loading truck and the ability to compete with jobs normally associated with an overhead crane. Loads could be handled from one side and lifted and turned to load on the opposite side. Lifting capacities were from 1-5 tons in 1 ton increments, and the company stated that larger capacities were available. Normal power was produced by two 30 Volt batteries, mounted one at each end of the machine but if required there was a diesel alternative. Another feature of note was the facility to raise and lower the ground clearance of the truck from a maximum 4.5 inches down to 0.5 inch without the need for stabilising jacks. This was achieved through a hydraulically operated mechanism coupled to the suspension system of the wheels at each end. This enabled the truck to handle standard reversible pallets at ground level with the machine on level or uneven floor surfaces. The operator could select power assisted, two or four wheel steering depending upon whether on the road or in a confined space.

The latest product to be released by Cleco Electric Industries was the dual side loading forklift truck. It was designed to accommodate the normal functions of reach truck and counterbalance with all the benefits of a side loading truck and the ability to compete with jobs normally associated with an overhead crane. Loads could be handled from one side and lifted and turned to load on the opposite side. Lifting capacities were from 1-5 tons in 1 ton increments, and the company stated that larger capacities were available. Normal power was produced by two 30 Volt batteries, mounted one at each end of the machine but if required there was a diesel alternative. Another feature of note was the facility to raise and lower the ground clearance of the truck from a maximum 4.5 inches down to 0.5 inch without the need for stabilising jacks. This was achieved through a hydraulically operated mechanism coupled to the suspension system of the wheels at each end. This enabled the truck to handle standard reversible pallets at ground level with the machine on level or uneven floor surfaces. The operator could select power assisted, two or four wheel steering depending upon whether on the road or in a confined space.

By James Brindley, Director, National Fork Truck Heritage Centre

If you would like to support the National Fork Truck Heritage Centre, please call James Brindley on 0780 195 4167

Comments are closed.