Jonathan Bennett Chairman of the SEMA Distributor Group (SDG) has noticed a distinct change in attitudes towards rack maintenance from end users of storage systems. He says; “Since compulsory independent auditing of SDG members was introduced in 2014, we have seen the market become much more discerning. As the multichannel approach to distribution continues to advance, these businesses need to know that not too far from their UKwide operations, there’s an SDG company that has the correct level of knowledge on storage design and qualified labour who can offer on-site support, typically at 24 hours’ notice.

“Our own business services the blue chip sector including major DIY retailers and supermarkets and we acknowledge that there’s a need to operate UK-wide. So, that’s where the SEMA Distributor Group comes into its own, as collectively, our group network has extensive geographical reach.

“Our own business services the blue chip sector including major DIY retailers and supermarkets and we acknowledge that there’s a need to operate UK-wide. So, that’s where the SEMA Distributor Group comes into its own, as collectively, our group network has extensive geographical reach.

“Everyone recognises the level of reassurance that the Gas Safe or NICEIC contractor delivers. In our industry, the Sema Distributor Companies operate on a similar principle. Our standards are set externally, we are independently audited regularly and, for 2017, quality measures are set to rise. It’s all about accountability and almost daily, I see the SDC logo requested on more and more tender lists. We now receive calls from companies who have first researched the SEMA website looking for an approved supplier.”

The SEMA Distributor Group was launched in September 2011 to bring together distributor members of the storage industry who wanted to collectively raise standards. It is part of SEMA, the British Trade Association of the Storage Equipment Industry. In addition to SEMA Distributor Companies (SDCs), SEMA has 165 members, including UK manufacturers, over 100 qualified SEMA Approved Racking Inspectors (SARIs), SEMA Approved Installations Companies (SAICs) and over 5,000 qualified installers who have been trained under the SEMA Equipment Installers’ Registration Scheme (SEIRS). Its courses are approved by RoSPA and the CSCS.

Safe storage follows a cyclical approach; safe manufacture offering full traceability of product. Whether the design is undertaken by the manufacturer or the SDC, it must meet SEMA’s strict codes of practice. The system is then installed by SEIRS qualified labour.

Regular onsite maintenance is the ongoing critical element of operating a safe storage regime. Companies who don’t operate a structured approach to rack inspection and repair may risk invalidating their commercial insurance policy.

Many SDCs employ an in-house SARI who, when he or she undertakes an inspection, provides a report and a traffic light system indicates actions required and over what timescale. A Red risk indicates serious damage immediate offloading of the rack is required with repairs using the OEM components required, in line with SEMA’s Code of Practice. Amber damage requires ‘timely action’ and normally within a four-week period. Green requires surveillance where defined damage limits are not exceeded as per the SEMA Code of Practice for the Use of Static Racking (available from the SEMA website).

Another SDC member, Elizabeth Porter believes that while many of the “big boys” operate within the requirements of PUWER and do meet the Employer’s Duty of Care, there are many medium sized businesses that could benefit from the expert support offered by an SDG company. She says; “Most companies wouldn’t chance not having an up to date Electrical Safety Report but the risk of an electrical fire is probably minimal in comparison to the likelihood of a racking collapse where FLTs can often cause damage to uprights day in and day out. A collapse will most likely have a domino effect which effectively kills the business, as there’s probably a loss of 50% of storage space, and damage to stock, not to mention the loss of reputation. The professional help of an SDG is only a phone call away.”

Jonathan Bennett sums up: “Ever wish someone else had done the leg work on health and safety, use of trained labour and correct storage design so you can sign on the dotted line? Our message to end issuers is that before instructing a storage distribution company, ask to see a current SDC Audit Certificate as proof that the correct health and safety standards are in place, they use only trained labour, storage is correctly designed and the firm carries appropriate insurance.”

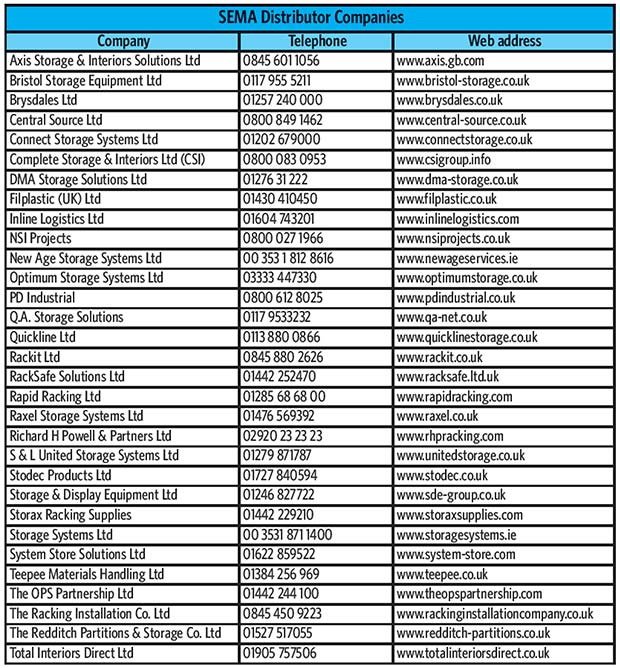

The group comprises some thirty members who are entitled to display the SDC logo as a measure of distinction. The SDC audit was the first scheme of its type for the storage industry.

A short video on the benefits of choosing a SEMA Distributor Company and a list of regional members is available at http://bit.ly/SDCfilm If you’d like to find out more about becoming a member, call the SEMA office on 0121 601 6359 or visit sema.org.uk

SEMA

Tel: 0121 601 6359

Comments are closed.