As the saying goes “efficiency is intelligent laziness”. As confidence continues to grow within industry, business owners across the UK are taking the security afforded by busier operations as an opportunity to look for intelligent ways to improve the flow of goods into, through and out of their facilities.

Improving the productivity of loading points within distribution facilities is highly topical for operational management, with designs firmly set on increasing loading capacity and flexibility. In purpose built sheds, ‘expensive’ equipment is increasingly sought-after; with decision makers attempting to design out operational barriers by focusing on the wider impact of their choices. Rather than simply the upfront price, it is the unseen costs associated with traffic backlogs and operational failures that are increasingly influencing the decision.

Improving the productivity of loading points within distribution facilities is highly topical for operational management, with designs firmly set on increasing loading capacity and flexibility. In purpose built sheds, ‘expensive’ equipment is increasingly sought-after; with decision makers attempting to design out operational barriers by focusing on the wider impact of their choices. Rather than simply the upfront price, it is the unseen costs associated with traffic backlogs and operational failures that are increasingly influencing the decision.

Modern loading bay solutions appear to be considered a worthwhile investment where operators can demonstrate their ability to eliminate operational complexity, health and safety risks or significant energy losses.

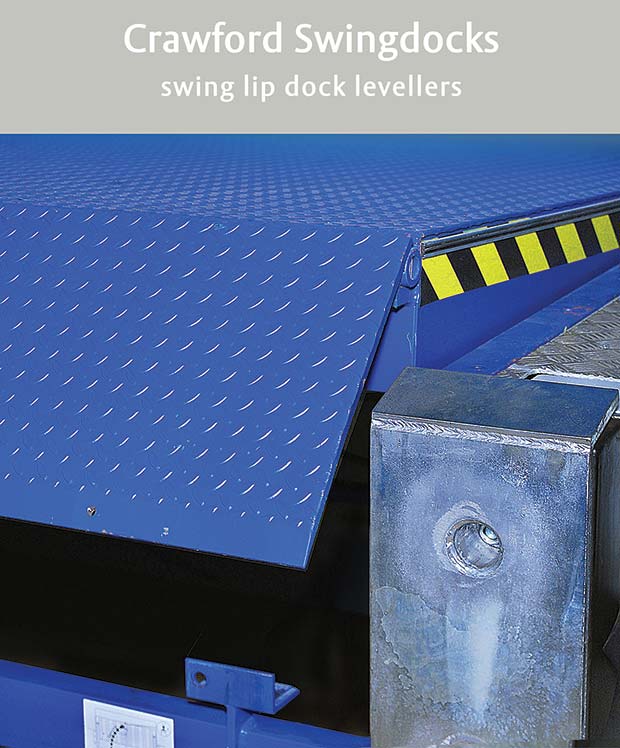

The uptake of telescopic lip dock levellers for end-user driven developments is testament to a change in thinking. The gravitation towards telescopic by those companies using the equipment every day, indicates that a higher initial price doesn’t necessarily dictate demand. Electro-hydraulically extendable telescopic lip levellers are easier to manoeuvre than the swing-lip alternative, and more economic with trailer bed space, too.

The most significant benefit of telescopic lip levellers is the flexibility afforded to operatives on the bay. As opposed to the fixed length lip of a swing leveller, a telescopic lip is extended by the operator meaning a safe connection can be ensured without the need to leave large spaces around trailer doors.

Adhering to EU legislation, the length of the leveller can be varied to ensure loading gradients stay within the required eight percent decreed by health and safety.

Allan Stockdale, Sales Director – Industrial Doors & Docking Solutions for ASSA ABLOY Entrance Systems said: “Crawford TeleDock levellers are designed to meet key industry challenges; they are highly efficient because they are easy to operate, safe and flexible enough to meet almost any loading challenge.”

Comprehensive service and maintenance plans are perhaps the most underappreciated route to efficiency. An out of service loading bay, at any stage of the manufacturing or distribution process, creates a bottleneck for the whole operation, and downtime is the ultimate efficiency drain. ASSA ABLOY Entrance Systems service network comprises over 100 skilled engineers across the UK and Ireland, offering 24-7-365 access to the UK’s largest dedicated door maintenance programme.

If efficiency really is “intelligent laziness” then any system that makes strategic loading easier or more intuitive can claim to fit the bill. Where telescopic lip dock levellers are concerned however, it could be argued there is an equally strong claim to both.

Comments are closed.